Vehicle Thermal Management Models and Tools

NREL's vehicle thermal management modeling tools allow researchers to assess the trade-offs and calculate the potential benefits of thermal design options.

CoolSim HVAC Model

CoolSim provides a transient heating, ventilating, and air conditioning (HVAC) modeling tool in the MATLAB/Simulink environment for both integrated Autonomie and standalone simulation.

This NREL-developed HVAC system model uses a one-dimensional finite-volume formulation to solve energy, momentum, and continuity equations. Models of all the system components—compressor, condenser, expansion device, and evaporator—are included. Both mechanically and electrically driven compressor models are available to users. A mechanical model built in CoolSim was validated to steady-state-component and system data. Results were within 3% of the data.

Download CoolSim standalone typical light-duty vehicle mechanical A/C system and electrical A/C system models. For more information about CoolSim, please email CoolSim@nrel.gov.

Download HVAC ModelA 10 times faster quasi-transient and a 100 times faster mapped-component model have been developed and will be released in the future. Autonomie-integrated versions will also be available soon. Heavy-duty and thermal system models are in development.

While NREL does not provide technical support for CoolSim, we welcome your feedback on the tool. Email your feedback or report any problems to CoolSim@nrel.gov.

CoolCalc

CoolCalc simulates energy used for climate control in truck cabs and assesses the impact of thermal load-reduction technologies. Researchers can calculate the potential benefits of thermal load reduction options in a range of use and weather scenarios. CoolCalc is built on NREL's original OpenStudio development and is a plug-in extension of Trimble's SketchUp software. DOE's EnergyPlus program is used as the heat transfer equation solver.

The tool's graphical user interface makes it possible for industry partners to quickly determine the impact of thermal load-reduction strategies. CoolCalc allows parametric trade-off studies to rapidly evaluate the impact of design factors (such as insulation thickness, material properties, and geometries) on HVAC loads.

For more information on how to become a CoolCalc partner and access the tool download, contact Jason Lustbader.

Truck cab models drawn from computer-aided design geometry using CoolCalc (left and center); a model with computational-fluid-dynamics flow overlay (right) indicating areas of heat absorption and loss. Illustrations by Jason Lustbader, Matt Jeffers, and Larry Chaney, NREL

Vehicle Solar Load Estimator

The Vehicle Solar Load Estimator (VSOLE) software calculates the solar load on a vehicle passenger compartment based on vehicle geometry, vehicle orientation, solar radiation source, and window glazing properties.

VSOLE1.0 is written in MATLAB and features an easy-to-use graphical user interface. The program takes into account the angle of incidence and calculates the transmitted, reflected, and absorbed power based on the radiation source, vehicle geometry, vehicle orientation, and glazing type. All glazing surfaces are assumed to be flat, and to have constant thickness, uniform properties, and regular shape. The calculation of the optical properties as a function of wavelength and angle uses a single-pane approximation for glass. The transmitted, reflected, and absorbed power can be calculated at a specific time, a range of times, or a range of orientations.

Contact Jason Lustbader for additional information and VSOLE download instructions.

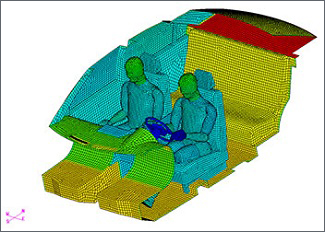

Cabin model used to predict human thermal comfort.

Illustration by Larry Chaney, NREL. Cabin geometry from Halla Visteon Climate Control.

Other Thermal Analysis Tools

Other thermal analysis tools—computational fluid dynamics, thermal radiation, and human thermal comfort software—are used to evaluate the potential effectiveness of strategies to reduce climate control loads.

Using vehicle computer-aided design geometry, computational fluid dynamics meshes are developed. Thermal soak simulations and transient cool down and human comfort simulations are performed. Additionally, one-dimensional lumped capacitance thermal models are used to simulate the performance of refrigerant and fluid systems.

Share