Energy Storage Thermal Performance

NLR is one of the few laboratories equipped to evaluate the thermal performance of batteries at the materials, cell, module, pack, and system level.

Battery energy storage systems must operate at maximum efficiency, perform at optimal temperatures in a range of conditions and climates, and endure thousands of charging cycles. NLR's Battery Thermal Management Laboratory works closely with industry partners to rigorously evaluate batteries and other energy storage technologies.

NLR is recognized as the nation's leader in battery thermal management research and development due to our unique approach to providing comprehensive thermal evaluation of batteries across material, cell, module, pack, and system levels. NLR's assessments of thermal behavior, capacity, lifespan, and overall performance are factored into full-system battery integrations.

The U.S. Department of Energy, the U.S. Advanced Battery Consortium (USABC), and other industry partners rely on NLR to measure thermal properties of batteries and evaluate the heat transfer effects of cycling on energy storage components and subsystems. Related evaluations performed across NLR laboratories examine what triggers lead to energy storage failure, including reactions to external damage.

Thermal Experimentation and Characterization

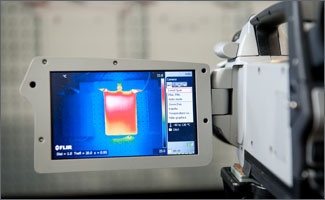

NLR experts measure and analyze the heat generation, efficiency, durability, and heat capacity of energy storage components and systems under specified charge/discharge cycles using the lab's R&D 100 Award-winning Isothermal Battery Calorimeters (IBC), infrared thermography, environmental chambers, battery cyclers, and other equipment in NLR's Battery Thermal Management Laboratory.

NLR's IBCs are the only calorimeters in the world capable of determining heat levels and battery energy efficiency with 98% accuracy, providing precise measurements through complete thermal isolation. In addition, energy storage researchers use differential scanning calorimeters and accelerating rate calorimeters to examine thermal properties more closely at the materials level.

NLR researchers also use thermal imaging to observe temperature distributions and identify potential trouble spots in energy storage cells and modules. The information from thermal imaging is used in model validation and in developing optimal thermal management system designs.

Battery Efficiency

Precise measurement of energy efficiency distinguishing stored energy from waste heat enables vehicle and battery manufacturers to better estimate energy consumption. NLR's infrared imaging thermally maps and pinpoints areas of high heat generation within batteries and across energy storage systems. NLR uses a range of battery cyclers to simulate a full spectrum of profiles based on real-world circumstances.

Battery Durability and Lifespan

Optimization of batteries cycling conditions is used to increase the cycle life of these systems and prolong when they need to be replaced. NLR conducts long-term electrical/thermal performance assessments with established USABC evaluation protocols to assess the life cycle and lifespan of batteries. NLR uses a combination of thermal imaging, cycler-generated simulations, and calorimeter measurements to assess long-term performance and identify improvements with the potential to extend lifespan.

System-Level Design and Modeling

NLR also uses a series of models and analytical tools to assess thermal performance. A 3D thermal-fluid dynamics model helps optimize the performance of energy storage systems with multi-scale modeling of thermal management components, including blowers, pumps, flow channels, and cooling fluids. NLR's energy storage models establish heat generation rate and cooling requirements for various driving, geographic, and seasonal scenarios, which are validated through laboratory measurements.

NLR researchers use the battery system life-predictive model, a systems-level thermal empirical design model, to assess battery:

- Performance, lifespan, and cost trade-offs

- Excess power and energy sizing requirements

- Probability of degradation, including mechanical stress and fracturing

- Warrantees, second uses, and other techno-economic factors.

Contact

Share

Last Updated Dec. 6, 2025