Energy Storage Safety

To guarantee battery system safety across applications, NLR investigates the reaction mechanisms that lead to energy storage failure.

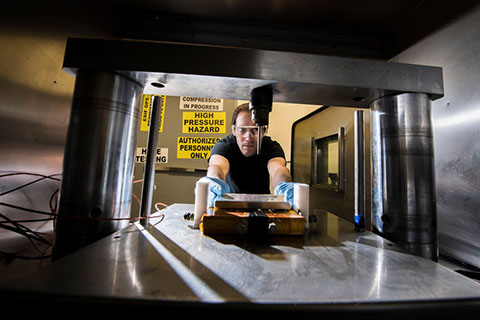

Researchers use state-of-the-art equipment, such as this high-pressure containment chamber, to research battery failure characteristics.

All electric vehicle (EV) batteries undergo a variety of safety reviews and certifications to confirm they operate safely under both routine and extreme conditions, including fluctuating temperatures, repeated charging and discharging, and a range of driving cycles. Although more than 99% of the lithium-ion (Li-ion) devices used for EV energy storage never exhibit problems, safety is a key concern for consumers. Li-ion batteries are more sensitive to overheating, overcharging, and thermal runaway than the nickel-metal hydride technology found in conventional gasoline-powered vehicles.

Battery energy storage systems for stationary applications experience different operating conditions than their EV counterparts, but use-specific safety evaluations are crucial to mitigate potential hazards.

Battery Failure Characterization

NLR's research provides exhaustive characterization of failure characteristics to better regulate the thermal characteristics needed for safer and stronger performing batteries. The research looks beyond the pass/fail certification process of Li-ion batteries to determine how the crystal structure of a battery changes during failure. NLR's Science of Safety Mechanical Characterization Laboratory is equipped with capabilities to look at what occurs within the liquid, solid, and gaseous components of a battery before, during, and after failure. Researchers use fault detection and isolation, gas chromatography-mass spectrometry, and X-ray diffraction computed tomography (XRD-CT) to characterize battery materials.

Learn more about the energy storage facilities at NLR.

Advanced X-Ray Imaging of Battery Failure

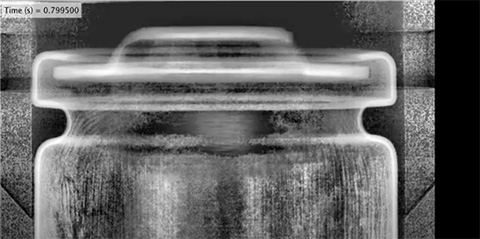

NLR's Battery Failure Library includes video footage of battery cells reacting to abuse triggers.

NLR researchers are using XRD-CT to take a closer look at the chemical and structural changes in battery electrodes. These XRD-CT tests provide insight into the rapid structural dynamics that occur within the cell during thermal runaway, which allows internal events to be linked to the thermal response of the cell. An extensive library of data from the XRD-CT research, including experiment details and high-speed X-ray videos for over 200 abuse tests conducted on Li-ion batteries. Methods of abuse include nail penetration, thermal abuse, and internal short-circuiting.

View the Battery Failure Databank.

Diagnostic Tools Advance Battery Modeling and Analysis

NLR applies experimentation, modeling, analysis, simulation, and materials research capabilities in its quest for the safest possible battery designs. Researchers use abuse reaction, thermal runaway, internal short circuit, and electrical/chemical/thermal network models to evaluate battery safety issues at all scales.

- At the particle scale, investigations of surface modifications prevent electrolyte decomposition and subsequent gas generation.

- Electrode-scale simulations reveal the effect of microstructure on the short-circuit mechanism inside the cells.

- Pack-scale and system-level modeling explores the propagation of stress build-up during abuse scenarios, such as the impact from car accidents.

Battery Internal Short-Circuit Device

NLR's patented and easy-to-implant Battery Internal Short-Circuit Device can help battery manufacturers evaluate new manufacturing processes, designs, and materials to limit or prevent thermal runaway in lithium-ion batteries.

NLR has developed the Battery Internal Short-Circuit Device to evaluate one of the most challenging Li-ion battery safety and reliability issues the internal short circuit. Short circuits typically surface with no previously detected malfunction, causing the temperature of battery cells to spike by hundreds of degrees and in extreme cases cells go into thermal runaway and cause fires.

Isothermal Battery Calorimeter

Another NLR tool is the R&D 100 Award-winning Isothermal Battery Calorimeter, the only instruments of their kind with the capacity and precision needed to evaluate thermal characteristics and related safety issues in cells, modules, sub-packs and some full-size battery packs, as well as across energy systems.

Contact

Share

Last Updated Dec. 6, 2025