Fuel Chemical Analysis and Properties Research

NLR studies how molecular structure leads to fuel properties and how these properties impact engine operation efficiency and nitrogen oxide and soot emissions.

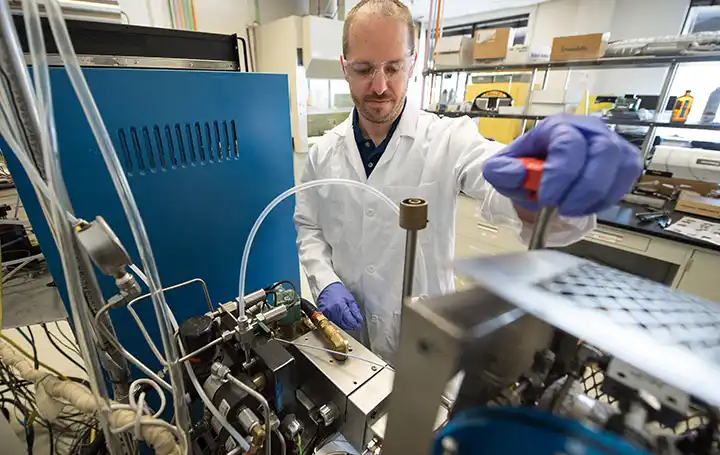

Photo by Joe DelNero, National Laboratory of the Rockies

Through fuel property measurements at engine relevant conditions, fundamental combustion reaction kinetics, and high-fidelity combustion simulations, we provide the crucial connection between fuel properties and molecular structure so fuel producers can target design and production of fuels with the right chemistry for the intended application.

Types of Fuel Chemical Analyses

We evaluate biofuels and conventional fuels for gasoline and diesel engine compatibility as well as for maritime and aviation applications.

- Research octane and motor octane number by an Advanced Fuel Ignition Delay Analyzer

- Reid vapor pressure

- Heat of vaporization (HOV) via a novel in-house method

- Distillation

- Oxidation stability

- Detailed hydrocarbon analysis (DHA)

- Flash point

- Heat of combustion

- Acid number and peroxide content

- Cetane number by an Advanced Fuel Ignition Delay Analyzer

- Cloud point and pour point

- Simulated distillation

- Viscosity, density, and surface tension

- Oxidation stability

- Biodiesel cold soak filter blocking tendency

- Flash point

- Heat of combustion

- Jet fuel speciation (GCxGC time-of-flight mass spectrometer)

- Freezing point

- Simulated distillation

- Cetane number by an Advanced Fuel Ignition Delay Analyzer

- Surface tension at a temperature range of -35°C–400°C and pressure range of 1–80 bar

- Viscosity at a temperature range of -40°C–315°C and pressure range of 1–80 bar

- Density at a temperature range of -10°C–200°C and pressure range of 1–500 bar

- Flash point

- Heat of combustion

See information about our synthetic aviation fuels research.

- Acid number

- Density

- Flash point

- Pour point

- Viscosity

- Fuel blend stability

See information about our marine fuels research.

Advanced Fuel Ignition Delay Analyzer

The research-grade Advanced Fuel Ignition Delay Analyzer (AFIDA), a constant-volume combustion chamber platform for fuel ignition kinetics research, was acquired to expand capabilities in screening small quantities of fuel compound candidates. This equipment significantly increases the range of experimental conditions and throughput to map ignition delay of novel fuel compounds and blends. The AFIDA offers greater experimental flexibility compared to NLR's Ignition Quality Tester (IQT) platform; a high-pressure (1,200- bar) direct-injection system to minimize spray physics effects; and an autosampler carousel to enable automatic operation for experiments with various fuels, pressures, and temperatures.

Detailed Hydrocarbon Analysis

The DHA-derived parameter particulate matter index (PMI) is a widely used metric for ranking the particulate matter formation tendency of gasolines, including gasolines containing biofuels. Particulate matter consists of fine particles that have negative impacts on human health. Particulate matter emissions from cars and trucks are regulated by government agencies worldwide.

PMI is calculated from the DHA, considering the properties of each individual component. NLR's fuel chemistry and engine combustion research has shown that particle formation from biomass-derived oxygenates is not accurately predicted by PMI because some oxygenates have low energy barrier reaction pathways to soot formation.

Additionally, alcohols such as ethanol have a much higher HOV than gasoline, and when blended into gasoline the increased evaporative cooling can cause more particles to form from the aromatic compounds in gasoline under some conditions. The DHA can also be used to calculate the HOV of complex mixtures such as gasoline-ethanol blends. Researchers examine how to predict the distillation curve of gasoline from the DHA as well as other properties.

For more information, read A Review and Perspective on Particulate Matter Indices Linking Fuel Composition to Particulate Emissions, SAE International Journal of Fuels and Lubricants (2022).

Novel Gasoline Heat of Vaporization Measurement Method

NLR has developed a method for measuring HOV as the fuel evaporates using a differential scanning calorimetry/thermogravimetric analysis (DSC/TGA) instrument. The method has been applied to market gasoline samples, as well as blends of alcohols in gasoline, and has been modified to provide the HOV of diesel-boiling range components. Researchers use a high-pressure DSC to provide enthalpy diagrams of jet fuel.

Our combined DSC/TGA and high-pressure DSC capabilities can be used to generate these data, including the heat capacity at constant pressure versus temperature measurements.

Ignition Quality Tester

The IQT is a constant volume combustion vessel that is used to study ignition properties of liquid fuels. In addition to the main combustion unit, the IQT includes temperature controllers and other electronics and a closed-loop cooling system. A high-speed pressure transducer measures chamber pressure to detect fuel ignition. Fuel samples are injected into the combustion chamber through a pintle-type injector nozzle.

Publications

Read about related studies and browse all NLR publications about fuel chemical analysis and properties R&D.

Measurement of Spray Chamber Ignition Delay and Cetane Number for Aviation Turbine Fuels, Energy & Fuels (2025)

Properties and Autoignition Reactivity of Diesel Boiling Range Ethers Produced from Guerbet Alcohols, Fuel Communications (2025)

Fuel Property Evaluation of Biodiesel Containing β-hydroxy FAME from Engineered Microorganisms, Fuel Communications (2024)

Properties That Potentially Limit High Level Blends of Biomass-Based Diesel Fuel, Energy & Fuels (2024)

Designing High-Performance Fuels Through Graph Neural Networks for Predicting Cetane Number of Multicomponent Surrogate Mixtures, SAE Technical Paper (2023)

A Review and Perspective on Particulate Matter Indices Linking Fuel Composition to Particulate Emissions, SAE International Journal of Fuels and Lubricants (2022)

Heat of Vaporization and Species Evolution During Gasoline Evaporation Measured by DSC/TGA/MS for Blends of C1 to C4 Alcohols in Commercial Gasoline Blendstocks, SAE International Powertrains Fuels & Lubricants Meeting (2019)

Contact

Senior Scientist and Manager, Fuels and Combustion Science

Share

Last Updated Dec. 6, 2025