Battery Recycling Supply Chain Analysis

NLR's lithium-ion (Li-ion) battery recycling supply chain research explores opportunities to strengthen and secure U.S. supply chains with detailed assessments, benchmarking, and analyses to identify gaps and ensure manufacturing resiliency.

Featured Tool

Growing demand for Li-ion batteries is increasing demand for raw materials—such as cobalt, nickel, and lithium—that are not domestically produced or refined in sufficient quantities. Li-ion battery recycling is one opportunity to enable supply chain resilience in the U.S and globally.

The intersection of different markets, operations, and policies will impact global electrification efforts. To understand more about this challenge, NLR researchers developed the LIBRA: Lithium-Ion Battery Resource Assessment Model.

Key Impacts

NLR's analysis experts have been instrumental in understanding how the growing electric vehicle (EV) market will impact the Li-ion battery recycling supply chain. NLR's research has informed numerous projects and policies that lay the groundwork for the battery recycling infrastructure of the future.

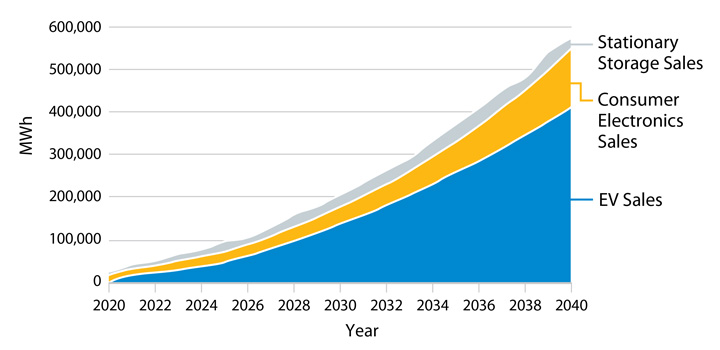

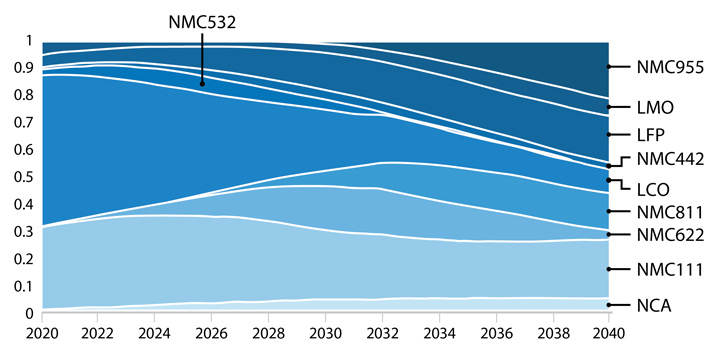

(Left) Early LIBRA analysis evaluated the total U.S. annual Li-ion battery sales by battery factor to emphasize the scope of impact EV sales will have on the market. (Right) LIBRA estimated how the distribution of battery chemistries used in Li-ion batteries would evolve over time to show how recycling might change over time.

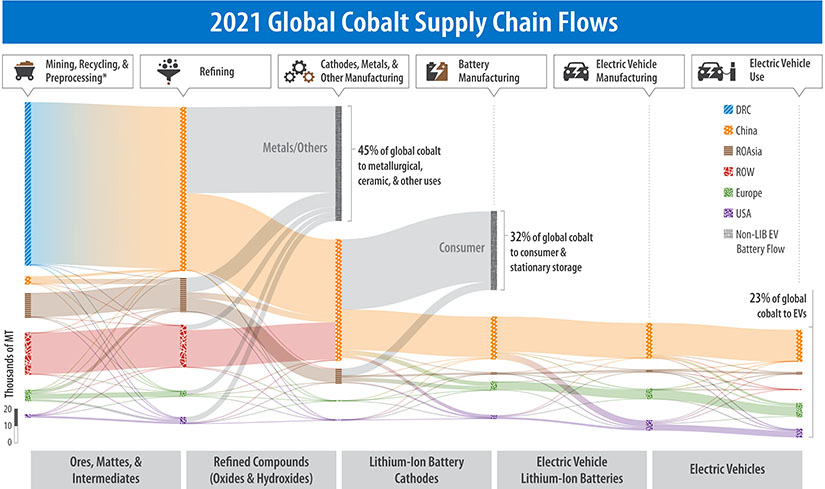

NLR researchers continue to track the global flow of different critical materials used in today's energy systems. This data, mapped for cobalt in the graphic below, illustrates the movement of different materials throughout the Li-ion battery supply chain, from mineral extraction to EV application. This emphasizes the importance of expanding domestic mineral sources and highlights how Li-ion battery recycling would help bridge a critical gap in domestic access to battery materials.

This graphic illustrates the flow of cobaltthrough the Democratic Republic of Congo

(DRC), China, Europe, the rest of Asia (ROAsia), the rest of the world (ROW), and

non-Li-ion EV battery flow. This data comes from NLR Analysis, USGS 2022 Mineral

Commodity Summaries, International Trade Centre, and the Battery Material Manufacturing

database “Global Cobalt Outlook 2020–2030.”

*Mining, Recycling, and Preprocessing products includes ores, naturally occurring

solids containing cobalt, and mattes and intermediates (30–100% cobalt).

Featured Projects

NLR researchers recently used LIBRA to estimate how recycling scrap material from consumer battery and cathode manufacturing would impact the raw material supply for new manufacturing. Manufacturing scrap materials will dominate the Li-ion battery waste stream until 2040 when end-of-life batteries from EVs become available for recycling, kick-starting the recycling industry and closing the materials gap for manufacturing.

This analysis demonstrates that manufacturing scrap and end-of-life batteries can be a substantial source of raw materials for domestic manufacturing, offering greater supply chain resiliency for U.S. battery manufacturers.

NLR researchers used LIBRA to evaluate the impact and importance of battery chemistry and sorting in the recycling supply chain. Commercially available Li-ion batteries include a range of different chemistries, and these findings show that automated sorting can help recyclers selectively process batteries based on the material makeup.

In this study, LIBRA emphasized how automated sorting will be particularly impactful for cobalt recovery before 2035, before low-cobalt battery designs become more popular in the marketplace. At $23 per pound for cobalt in 2021, targeting high-cobalt chemistries can help incentive investments by making Li-ion battery recycling more profitable.

Publications

Impact of Automated Battery Sorting for Mineral Recovery from Lithium-Ion Battery Recycling in the United States, Resources, Conservation, and Recycling (2023)

Battery Energy Storage Scenario Analyses Using the Lithium-Ion Battery Resource Assessment (LIBRA) Model, NLR Technical Report (2023)

Economics and Challenges of Li-Ion Battery Recycling from End-of-Life Vehicles, Procedia Manufacturing (2019)

Contact

Share

Last Updated Dec. 7, 2025