LIBRA Model Guides Development of Sustainable Battery Supply Chain

Imagine the future of clean energy and you might picture mind-boggling inventions, science-fiction settings, and cutting-edge technologies developed at the National Renewable Energy Laboratory (NREL). No matter what the future holds, next-generation technologies will demand large amounts of energy materials, which can sometimes be scarce and difficult to access. Every innovation is incomplete without robust and secure manufacturing supply chains to support their development.

The U.S. Department of Energy (DOE) has emphasized the importance of secure and resilient supply chains to guide the clean energy transition, developing a comprehensive strategy with support from NREL research. Computer models developed at NREL provide detailed assessments, benchmarking, and analyses to identify supply chain gaps and ensure supply chain resiliency.

At the leading edge in the national laboratory system is one such tool—the Lithium-Ion Battery Resource Assessment Model (LIBRA)—which is helping researchers better understand the numerous factors that impact the lithium-ion (Li-ion) battery materials supply chain. Developed at NREL with funding from DOE, LIBRA uses powerful system dynamics modeling to analyze the supply chain and evaluate the economic viability of Li-ion battery manufacturing, reuse, and recycling.

As governments worldwide move to reduce annual carbon emissions through vehicle and grid electrification, Li-ion batteries have emerged as the favored electrochemical energy storage solution, particularly for electric vehicles (EVs). Li-ion batteries offer performance, energy density, cost, and cycle-life benefits. However, electrification efforts are complicated by various intersecting factors, including differences in markets, operations, and policies. In addition, Li-ion batteries may contain critical materials in short supply, such as cobalt, with few natural resources available domestically.

“LIBRA can compile and simplify how various factor changes—such as costs, battery adoption scenarios, and international actions—affect long-term trends in the battery supply chain,” said Maggie Mann, NREL manager of the Mobility Infrastructure and Impacts Analysis group. “Although LIBRA can’t predict the future, this model allows researchers to ask and answer ‘what-if’ questions to gain insights into a complex and rapidly evolving industry. LIBRA offers a detailed and consistent approach to guide research and investments to secure the Li-ion supply chain, optimize recycling processes, and ensure resiliency and sustainability for nationwide grid and vehicle electrification.”

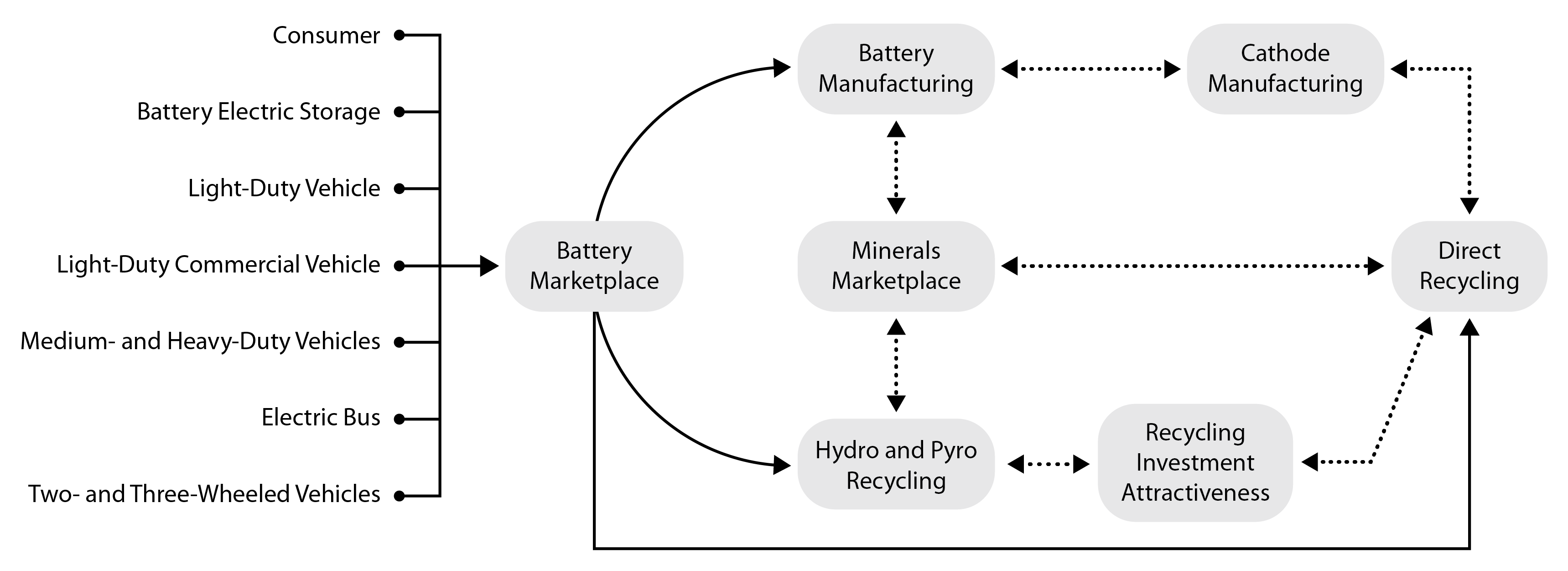

This illustration shows how LIBRA considers a multitude of factors to determine how market demand (left) can impact the battery marketplace and resource availability. Graphic by NREL

LIBRA’s power lies in system dynamics analysis, which tracks the supply and flow of materials and costs over time for Li-ion battery manufacturing and recycling supply chains. The tool also includes advanced feedback loops that inform calculated changes throughout the stages of the supply chain. As a result, LIBRA can provide essential information on material availability to meet rising battery demands and evaluate the buildout of the manufacturing and recycling industries. LIBRA can also evaluate the growing demand for Li-ion batteries due to EV market adoption, helping reduce impacts from global policy actions on the U.S. supply chains.

“LIBRA shows how technological or market changes can affect long-term trends in the battery materials supply chain,” said Dustin Weigl, NREL mobility research analyst. “For example, if we extend the lifetime of EV batteries to reduce the overall environmental impact of Li-ion batteries, how might that lower the availability of recycled materials? There are many factors at play.”

Circular Economy for Energy Materials

A circular economy for energy materials reduces waste and preserves resources by designing materials and products with reuse, recycling, and upcycling in mind from the start.

Focus on Sustainability, Recycling

Time and again, LIBRA has emphasized the importance of Li-ion battery recycling as part of our clean energy future. Developing a robust Li-ion battery recycling industry would help bridge a critical gap in domestic access to battery materials while significantly reducing the environmental impact of EVs. The Li-ion battery recycling industry in the United States is relatively new—yet fortunately, LIBRA is on hand to guide research and investments to optimize recycling processes.

“LIBRA tracks the movement of lithium, cobalt, nickel, and other elements through the supply chain: first as raw materials for cathode manufacturing, into battery manufacturing, installation, and finally retirement—when the battery can be recycled through hydrometallurgy, pyrometallurgy, or direct recycling methods,” Weigl said. “Over the years, LIBRA has provided insights into the economic viability of different recycling methods, even highlighting the regional potential of recycling to offset mineral imports.”

In a recent Resources, Conservation and Recycling journal article, researchers used LIBRA to evaluate the impact and importance of battery chemistry and sorting in the recycling supply chain. Commercially available Li-ion batteries encompass a range of different chemistries, and findings show that automated sorting can help recyclers selectively process batteries based on the material makeup. In particular, recyclers can target high-cobalt chemistries to maximize cobalt recovery, incentivizing recycling investments by making recycling more profitable.

Adaptable, Forward-Thinking Analysis

Currently, LIBRA considers five different EV types, consumer electronics, and stationary grid storage batteries to understand interconnections between battery manufacturers and market demands, including future applications and developments.

“We are constantly updating LIBRA’s model structure and data based on the latest developments within the transportation and recycling industries,” Weigl said. “Technological advancements move quickly, but LIBRA is designed to adapt with next-generation cell chemistries, battery designs, and storage systems.”

Learn more about NREL’s energy storage and sustainable transportation research. And sign up for NREL’s quarterly transportation and mobility research newsletter, Sustainable Mobility Matters, to stay current on the latest news.

Last Updated May 28, 2025