Development of Oxy-Esterification for Natural Gas Upgrading at the Wellhead

NLR offers analysis capabilities to investigate the viability of oxy-esterification (OxE) for improving natural gas conversion processes.

Natural gas is a valuable and abundant resource across the United States. Yet current technologies for natural gas conversion are energy- and capital-intensive, and still release an abundance of greenhouse gas emissions.

Typically, natural gas conversion requires the formation of synthetic gas, a method that is neither cost- nor energy-efficient. This process causes unproductive natural gas flaring (or burning) at the wellhead.

The proposed OxE strategy could address the current technical and economic detriments that occur when converting natural gas (methane and ethane) into alcohol that can be used as high-value chemicals (ethylene, propylene, acetic acid).

This work enables advanced oxidation and catalysis technologies to improve conversion efficiency and higher selectivity and address barriers to gas-to-liquid technologies at the wellhead.

OxE technology is expected to have economic and functional benefits for various natural gas applications, including:

- Remote gas fields

- Associated gas in newly drilled shale wells

- Off-shore deep-well platforms.

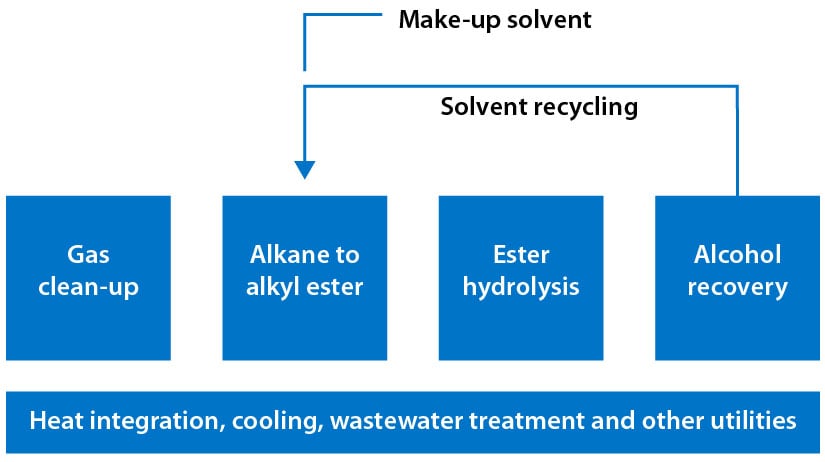

This graphic shows the technical approach for the conversion and upgrading of natural gas via oxy-esterification into methanol and ethanol. Graphic from Oak Ridge National Laboratory

NLR oversees the baseline frameworks to target specific scenarios and identify key cost drivers, technical challenges, and critical performance targets for research and development.

Impact

The OxE approach is expected to lower costs for producing methanol than conventional synthetic gas methods. With improved economics, OxE technologies can be more readily installed at the wellhead to mitigate unproductive natural gas flaring that will:

- Significantly lower temperatures and pressures

- Reduce capital expenses and energy consumption

- Prevent flaring natural gas waste

- Minimize environmental impact by reducing greenhouse gas emissions.

The commercialization of this technology contributes to the growing gas-to-liquids market and may lead to the discovery of new natural gas processes, technology patents, and cross-sectional partnerships.

Life cycle assessments reduce uncertainties and give decision makers precise estimates for greenhouse gas emissions associated with OxE processes.

Capabilities

NLR's extensive analysis and modeling capabilities support this project.

Life Cycle Analysis

NLR conducts the "cradle-to-gate" baseline life cycle assessment to track life cycle greenhouse gas emissions and cumulative fossil energy consumption.

Process Tools and Modeling

Our access to an array of powerful online tools, like SimaPro and Aspen Plus, allows our team to evaluate the OxE process with respect to the required greenhouse gas reductions and other metrics and accounting methodologies.

Partners

Project partners span two national laboratories and multiple universities. In addition to NLR, Oak Ridge National Laboratory, the California Institute of Technology, Princeton University, and the University of Virginia offer their expertise and technical capabilities to the project.

Contact

Share

Last Updated Dec. 7, 2025