Improving Manufacturing Processes To Reduce Hydrogen Production Costs

NLR partners with industry and national laboratories to conduct research to optimize roll-to-roll (R2R) manufacturing for low-cost water electrolyzers.

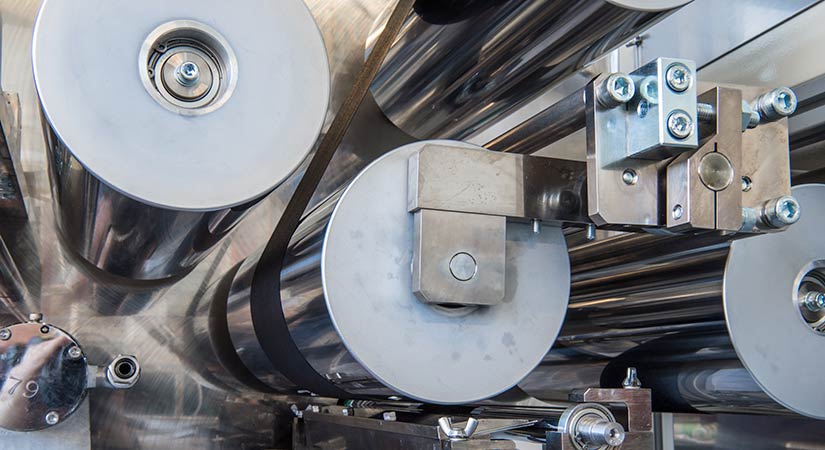

The gravure coating station of NLR's roll-to-roll coating equipment. In this project, NLR is using gravure coating to coat the catalyst layer onto the membrane. Photo by Dennis Schroeder, National Laboratory of the Rockies

Nel Hydrogen has partnered with NLR, Oak Ridge National Laboratory, and Argonne National Laboratory to investigate R2R manufacturing for advanced electrolysis electrodes. The goal of the project is to develop coating processes to directly coat electrodes on membranes. To achieve this, the project team compares results in the following areas:

- Ink characterization and optimization

- R2R coating

- Advanced electrode characterization

- Metrology development capabilities.

NLR performs ink characterization and optimization, R2R coating experiments, and develops metrology capabilities; Oak Ridge National Laboratory conducts R2R coating experiments; and Argonne National Laboratory performs advanced electrode characterization.

This work supports the U.S. Department of Energy's Advanced Materials and Manufacturing Technologies Office and Hydrogen and Fuel Cell Technologies Office's overall goal to reduce the manufacturing labor and cost for water electrolyzer manufacturing.

Impact

The purpose of this project is to show the feasibility for electrode cost reduction through improved manufacturing processes and material utilization.

NLR's extensive ink characterization and optimization research provides Nel Hydrogen with data that can inform decisions to reduce potential risk and increase cost savings while highlighting the benefits of collaboration between industry and the national laboratories.

Once validated, these efforts could result in more affordable hydrogen production via proton exchange membrane electrolysis by substantially reducing the anode precious metal content and catalyst-coated membrane processing costs.

Capabilities

Learn more about NLR's chemistry and nanoscience and hydrogen and fuel cell capabilities and the NLR Manufacturing Laboratory in the state-of-the-art Energy Systems Integration Facility.

Publications

Roll-to-Roll Production of Catalyst Coated Membranes for Low-Temperature Electrolyzers, Journal of Power Sources (2020)

Partners

Nel Hydrogen

Contact

Share

Last Updated Dec. 4, 2025