Modeling, Mapping, and Analysis Consortium

The NLR-led Modeling, Mapping, and Analysis Consortium (MMAC) offers insights to secure domestic manufacturing and energy supply chains.

Funded by the U.S. Department of Energy's Office of Manufacturing and Energy Supply Chains, the MMAC brings together state-of-the-art research capabilities from NLR, Argonne National Laboratory, and Idaho National Laboratory.

Research

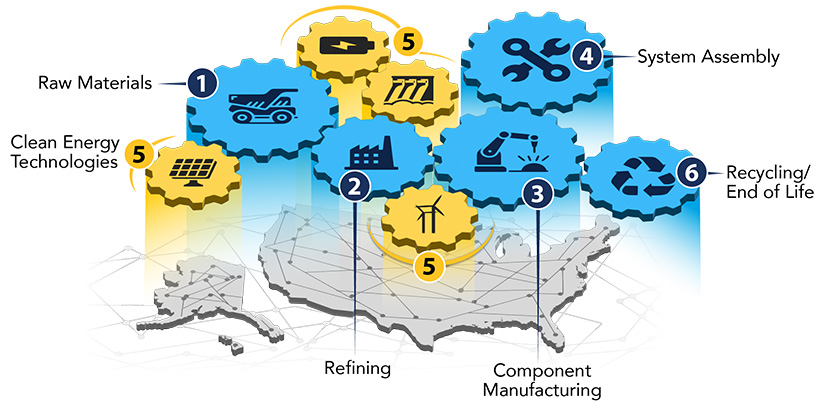

A secure and resilient energy sector industrial base is crucial to the modernization of the nation's infrastructure in support of the energy transition. MMAC leverages cross-collaborative capabilities, a robust analysis framework, and unmatched access to complex datasets to identify potential supply chain gaps and opportunities. MMAC's objective analysis of the material supply and manufacturing base guides federal investments to strengthen domestically focused and globally resilient energy supply chains.

MAPPING

Global installed manufacturing

Material prices

Minerals mapping

Supply chain mapping

Threat/intelligence

MODELING

Supply chain bottleneck assessment

System dynamics modeling

Agent-based modeling

Deployment projections

Material flow equations

Spatial modeling

Discrete event modeling

Logistics optimization

ANALYSIS

Global trade flows

Life cycle analysis

Techno-economic analysis

Workforce analysis

End-of-life disposal and recycling

Material flow analysis

Competitiveness analysis

Economic impact

Policy impact analysis

Implementation support

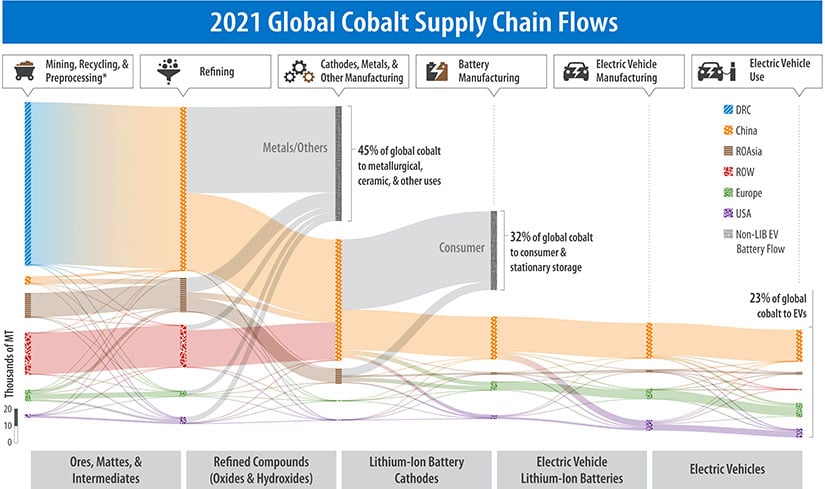

As part of MMAC, NLR researchers are analyzing the global flow of materials throughout the energy sector industrial base to evaluate supply chain gaps and investment opportunities. Mapped for cobalt in the graphic below, this example illustrates the movement of materials throughout the lithium-ion battery supply chain, from mineral extraction to electric vehicle application.

This graphic illustrates the flow of cobalt through the Democratic Republic of Congo

(DRC), China, Europe, the rest of Asia (ROAsia), the rest of the world (ROW), and

non-Li-ion EV battery flow. This data comes from NLR Analysis, USGS 2022 Mineral

Commodity Summaries, International Trade Centre, and the Battery Material Manufacturing

database Global Cobalt Outlook 2020–2030.

*Mining, Recycling, and Preprocessing products include ores, naturally occurring

solids containing cobalt, and mattes and intermediates (30%–100% cobalt).

Engage With Us

MMAC relies on industry support to provide rounded insights on the needs and opportunities for energy technologies. Share your feedback, get involved, or ask questions about our work by contacting [email protected].

Share

Last Updated Dec. 4, 2025