Plastic Packaging Recycling and Energy Manufacturing

NLR's research into plastic packaging recycling addresses challenges commonly associated with conventional materials and manufacturing, including reducing waste and improving U.S. manufacturing competitiveness.

With help from industry experts, NLR forges the way for new energy initiatives and technologies to improve the energy efficiency of materials manufacturing.

Multilayer plastic packaging is a highly engineered material with significant recycling challenges. Through the scalable, high-shear catalytic depolymerization of plastic packaging, NLR's work enables the recycling and upcycling of this challenging packaging material to enhance recycling processes and make U.S. manufacturing more cost-effective.

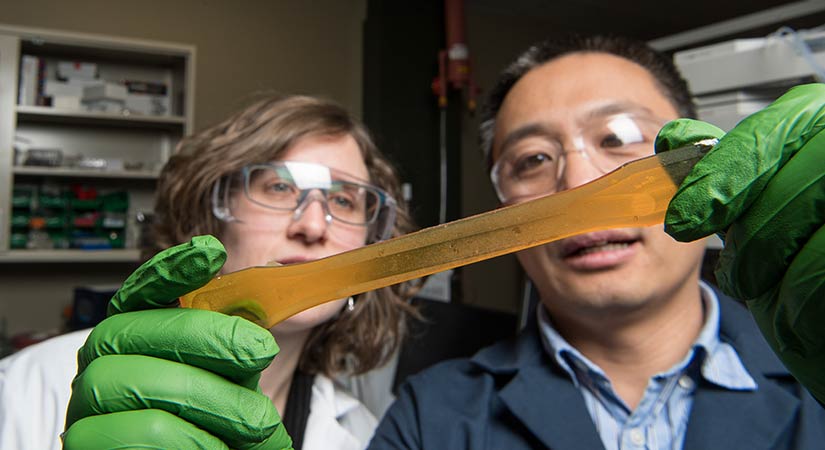

NLR analyzes the chemical composition and material characteristics of unprocessed and recycled multilayer plastics.

Partners

This work began with the Reducing EMbodied-Energy and Decreasing Emissions Institute (known as the REMADE Institute), a U.S. Department of Energy initiative made up of leading universities, corporations, and national labs. The national research consortium enables early-stage applied R&D to reduce energy and carbon emissions linked with industrial-scale materials production and processing. NLR has partnered with the University of Mass-Lowell's Department of Plastics Engineering to leverage facilities and technical expertise in materials deconstruction to pursue this research effort.

Learn more about the REMADE Institute.

Impact

By addressing knowledge gaps to mitigate technical and economic barriers associated with plastic packaging materials manufacturing critical to keeping U.S. manufacturing competitive, this project will significantly reduce material consumption and energy waste.

Insights from this project are:

- Providing understanding of structural changes that occur during film deconstruction

- Optimizing materials production and recycling processes

- Laying the foundation for future plastics recycling studies for multilayer films and other challenging materials.

Capabilities

NLR is home to the Magnetic Resonance Facility, which provides liquid and solid-state analysis capabilities for a variety of biomass, photovoltaic, and materials characterization applications across NLR. In addition to laboratory support, NLR provides technical input on depolymerization methods, guidance on application or downstream processing of the product stream, and recommendations on process improvements.

Analytical Techniques

NLR provides analytical expertise to evaluate the material and chemical characteristics of the recycled multiplayer plastics, including polymer structural analysis through solid state nuclear magnetic resonance spectroscopy and small molecule characterization to indicate material deconstruction.

Share

Last Updated Dec. 5, 2025