The Leading Edge: March 2021 Wind Energy Newsletter

In this edition of The Leading Edge, gearboxes receive a tune-up, turbine blades get a second wind, and wind energy plays a role in a circular economy for the coming energy transition.

News Stories

Research Strengthens Reliability as Wind Power Shifts into High Gear

Some of the most vital and heavily used components of wind turbines—which account for as much as 11% of overall wind turbine costs—are gearboxes. Gearboxes convert low-speed blade rotations to the high speeds required by most generators for electricity generation. Keeping these gearboxes in operating condition is essential to efficient and cost-effective wind power plant operation.

New tools from NREL make it possible to predict individual component reliability for the entire wind plant, reduce operation and maintenance costs through early design decisions, and take maintenance measures to extend gearbox life spans.

Beyond Technical Potential: NREL Explores the Challenges of Siting Wind in a Low-Carbon Future

In two related research efforts using detailed geospatial and power-sector modeling, NREL analysts determined that siting restrictions can have measurable impact on the technical potential for wind and future U.S. wind development, as well as electricity prices, emissions, and broader power system impacts.

NREL analysts used the Renewable Energy Potential Model to simulate setbacks between wind turbines and civil infrastructure, including every building, road, railway, transmission line, and radar tower in the country. Results point to the need for more integrated planning to balance local deployment decisions with new national decarbonization goals.

To learn more, read the full article and join NREL analysts Anthony Lopez and Trieu Mai for a free NREL Wind Energy Science Leadership Series Webinar: Siting Wind in a Low-Carbon Future from 9 to 10:15 a.m. Mountain Time on Thursday, April 8. Learn more about the webinar and how to register.

NREL Research Identifies Motivations, Methods for Achieving a Circular Economy for Wind Energy

Large wind turbine blades made from sturdy composite materials can be difficult to recycle. While numerous alternatives have been put forth to recycle and reuse these materials, little research has centered on the motivations that underly the creation of a circular economy for wind energy. Recent NREL research helps uncover these motivations and points to several process alternatives to recover material and energy from wind turbine blades.

NREL Discusses Circular Economy with High-Profile Partners in Fourth Partner Forum

NREL's fourth-annual Partner Forum focused on solutions to enable a circular economy for energy materials, including wind. The forum showcased NREL's stable of leading experts and opened its virtual doors to partners, extending invitations to companies from around the world to collaborate in designing a future replete with renewable energy solutions to the energy challenges of today.

Department of Energy's Advanced Manufacturing Office Funds Next-Gen Turbine Blades and More

Utility-scale wind turbine blade design and production has remained relatively unchanged over the past 25 years. An NREL-led project aims to take business into the next-generation with the help of a recently announced funding award from the U.S. Department of Energy's (DOE's) Advanced Manufacturing Office.

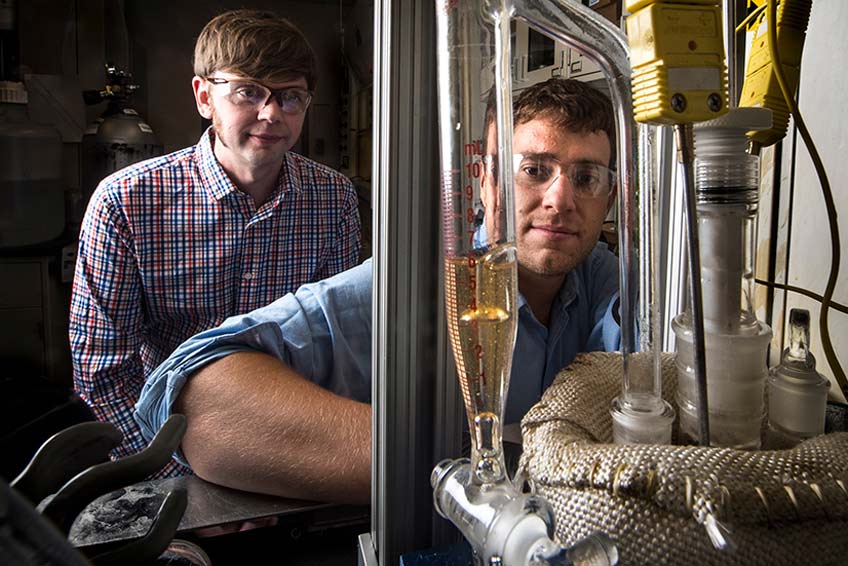

CoMET Aids Researchers and Partners in Reaching the Stars—and the Market

NREL's advanced thermoplastic resin system for wind turbine blades captured an R&D 100 Special Recognition: Market Disruptor Award. These prestigious awards honor pioneering advancements in science and technology. How did this concept progress from idea to award-winning innovation? It all began at NREL's Composites Manufacturing Education and Technology Facility, or CoMET, for short.

On the Radar

Building Better (Highly Flexible) Blades

The past few decades have experienced substantial reductions in the cost of wind energy largely because of increases in rotor size. These bigger rotors lead to low-specific-power wind turbines that can reduce the cost of energy by creating a greater swept area, which helps wind power plants more consistently capture energy and access higher wind speeds at elevated heights.

DOE's Big Adaptive Rotor project seeks to overcome transportation challenges associated with the creation of the giant, land-based wind turbines of the future. The project explores innovations such as highly flexible blades that simultaneously boost wind energy capture while resolving transportation challenges of moving giant wind blades by rail.

Downwind: In Case You Missed It

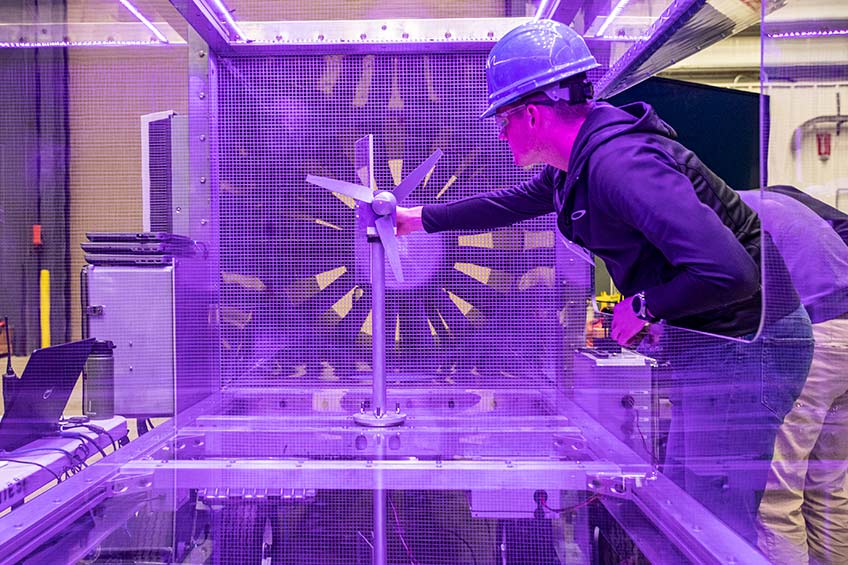

Department of Energy Announces 2022 Collegiate Wind Competition Challengers

DOE announced the 11 teams selected to participate in the 2022 Collegiate Wind Competition, scheduled to take place May 16–19, 2022, at the CLEANPOWER Conference and Exhibition in San Antonio, Texas.

The Collegiate Wind Competition challenges multidisciplinary teams of undergraduate students to develop a wind project plan based on market and siting considerations; raise awareness of wind energy in their local communities; and design, build, and test a model wind turbine against a set of rigorous performance criteria. Participants will integrate academic coursework with hands-on learning, gain valuable wind energy experience, and connect with today's industry leaders while preparing to enter the wind workforce.

Creativity, Persistence, and Passion Drive the Women of Wind Energy

In observance of International Women's Day (Monday, March 8), five women working in diverse wind energy roles at national laboratories funded by DOE's Wind Energy Technologies Office discussed the paths that led them to their work. They also shared their advice for other women interested in working in wind energy and their perspectives on what the wind and renewable energy industries can do to attract and retain female employees.

Publications

Quantifying Sensitivity in Numerical Weather Prediction-Modeled Offshore Wind Speeds through an Ensemble Modeling Approach

NREL authors published an article in Wind Energy, Quantifying Sensitivity in Numerical Weather Prediction‐Modeled Offshore Wind Speeds through an Ensemble Modeling Approach, that proposes best practices for quantifying the of numerical-weather-prediction-modeled wind speeds at hub height. Such practices are needed because of the difficulty of collecting wind observations at hub height—something that is especially true for offshore wind observations. Using an ensemble approach, researchers consider 24 setups to the Weather Research and Forecasting model, finding that standard deviation processes produce more consistent estimates and that model spread increases closer to the surface and on shorter timescales. Such findings provide a basis for further research into ensemble-based wind resource data sets.

Share