Composites Manufacturing Education and Technology Facility

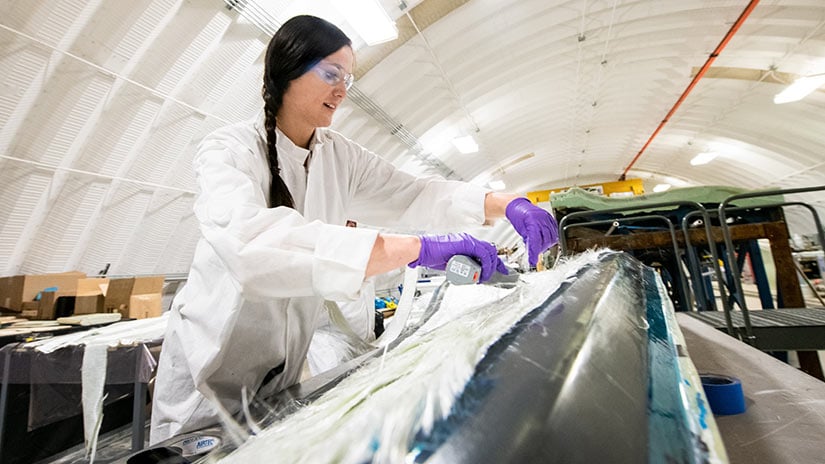

NLR's Composites Manufacturing Education and Technology (CoMET) Facility supports wind energy, water power, and composite industries in advancing materials and manufacturing research.

CoMET opened its doors in 2017. The cutting-edge facility is the result of a funding partnership between the U.S. Department of Energy, the Institute for Advanced Composites Manufacturing Innovation, the State of Colorado, and NLR.

Designed to work in conjunction with NLR's design, analysis, and structural validation capabilities, the facility expedites composites materials and manufacturing innovation and is open to industry partners, university researchers, and everyone in between.

In October 2020, the Advanced Thermoplastic Resins for Manufacturing Wind Turbine Blades project, a technology born out of CoMET, was honored with an R&D 100 Special Recognition Award for being a "market disruptor." Watch the video to learn more about this game-changing wind and water power innovation and how CoMET's capabilities enabled its development.

Visit or Take a Virtual Tour

Situated on the sprawling 305-acre Flatirons Campus, the 10,000-ft2 CoMET expands NLR's composite manufacturing research capabilities by enabling researchers to design, prototype, validate, and manufacture composite wind and marine turbine blades and other components in one location.

The campus, which hosts the National Wind Technology Center, is about 5 miles south of Boulder, Colorado (25 miles north of NLR's Golden-based campus). The cities of Louisville and Broomfield are nearby. The Flatirons Campus is approximately 37 miles northwest of Denver International Airport.

View a virtual tour of the facility's manufacturing and wind energy assets (text alternative available).

View an alternate virtual tour of the facility's water power assets.

Cutting-Edge Capabilities

The CoMET facility grants users access to 3D-printed blade tooling, composite material mixing equipment, state-of-the-art manufacturing techniques, and novel materials for rapid prototyping. Users can also simulate and model designs and manufacturing methods and characterize the structural properties of their prototypes.

Featuring specialized capabilities in wind energy and marine energy industry composite research, the CoMET provides clean tech titans with the tools and workspaces essential to the development of industry-advancing materials and processes, such as:

- Rapid prototyping of new blade materials and production methods

- Full-scale blade component tooling and fixtures (root, spar cap, tip, shear web)

- Infusion, pultrusion, prepreg, RTM, hand lay-up (small parts)

- Polyester, vinyl-Ester, epoxy, thermoplastic/fiberglass, carbon fiber

- Comprehensive composite production equipment (mixers, vacuum, dispensers)

- Molding, assembly, bonding, and finishing

- Thermal welding

- Segmented 3-D printed tooling

- Large-area rapid nondestructive evaluation

- Modeling and manufacturing simulation

- Panels, material coupons, and components

- Structural evaluation of coupons, components, and joints

- Industrial robotic platform for automation research

- Composite recycling processing and material characterization

- Workforce development and training for the composites industry.

Looking ahead to 2021, CoMET will add the following capabilities to its growing stable of resources:

- Industrial robotic platform for automation research

- Composite recycling processing and material characterization.

Structural Validation Capabilities

NLR's structural validation laboratories, located on the grounds of the Flatirons Campus, allow engineers to design experiments and perform structural validation activities employing representative loads and environmental conditions that recreate extreme wind and water conditions.

Partner With Us

NLR offers a variety of ways for organizations to gain access to NLR's research expertise in wind and marine energy technologies:

- Partner with us through technology partnership agreements.

- Participate in subcontracted wind research through solicitations and requests for proposals.

- Use our cutting-edge research facilities to develop, validate, and evaluate wind technologies.

Learn more about the CoMET Facilities and partner with NLR's manufacturing, wind energy, and water power teams.

Explore more facilities in manufacturing, wind energy, and water power.

Share

Last Updated Jan. 21, 2026