Geothermal Materials Sciences

NREL’s materials science research for geothermal applications develops materials that enable geothermal wells to last for decades under constant use and in extremely harsh conditions.

Novel Cements

In the field of ceramics, our researchers have developed novel cements that emulate the durable ancient Roman cements of two millennia ago. These cements leverage the high temperatures of the subsurface (and some unique feedstocks) to form crystalline products that behave as a robust matrix with low permeability. The combination of low permeability, thermal resilience, and resistance to chemical attack indicate that this new (old) class of material may be integral in the future of geothermal cementing.

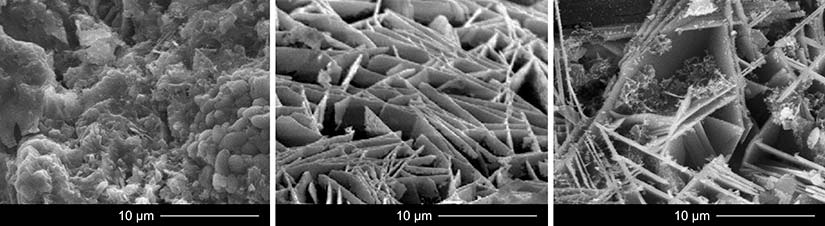

Micrographs of (a) ordinary Portland cement, (b) ancient Roman cement, and (c) cement

developed by NREL researchers.

Casing Materials

Metal casing material is equally important for ensuring leak-free, constant geothermal production. NREL is developing processes to harden mild steel, which will limit the impacts of abrasion. In typical mild steel, scratches can act as a nucleating point for corrosive processes, so limiting abrasion is important for extending the life of inexpensive metal components downhole.

Also important to extending casing lifetime is limiting the steel's exposure to working fluid. NREL researchers are developing novel polymer-oxide composite materials that are extremely chemically stable and effective even above 350°C. The goal is to coat steel components with the chemically resistant composites to make casings that have the strength and cost of steel with the inertness of state-of-the-art alloys. Coupling robust cement backing with hardened and encased steel casings could greatly extend the lifetime of geothermal wells and make them more economically competitive and technically viable.

Capabilities

- X-ray characterization – X-ray diffraction, X-ray fluorescence, and X-ray computed tomography provide insights into crystal structures (in many testing environments that can simulate in situ conditions), elemental composition, and micro-scale pore structure.

- Component and environmental testing – NREL can test and validate lab-scale components for physical (mechanical), chemical, and electronic properties. Most testing can be done at in-situ temperatures and conditions and provide information on long-term performance by leveraging advanced-aging techniques.

- Optical and electron evaluation – NREL's suite of optical and electron microscopes (SEM and TEM) can observe material properties from low magnification (10x) all the way down to crystal structures and atom interactions.

Publications

Thermomechanical Modeling of High-Temperature Bonded Interface Materials, Die-Attach Materials for High-Temperature Applications in Microelectronics Packaging (2019)

Metal-Organic-Inorganic Nanocomposite Thermal Interface Materials with Ultralow Thermal Resistances, ACS Applied Materials and Interfaces (2017)

Reliability of Emerging Bonded Interface Materials for Large-Area Attachments, IEEE Transactions on Components, Packaging, and Manufacturing Technology (2016)

View all NREL publications about geothermal research.

Contact

Share