Geothermal Manufacturing and Supply Chain Analysis

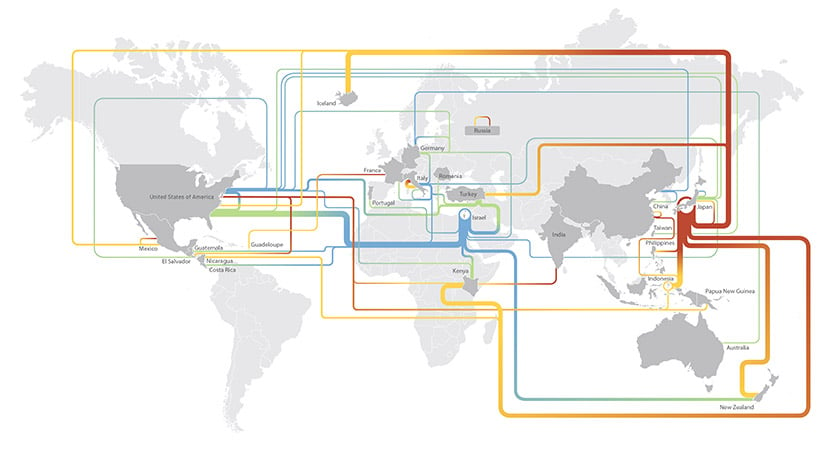

NLR conducts manufacturing and supply chain analysis for geothermal energy technologies, including cost analysis, supply chain mapping, and manufacturing location assessment.

NLR analyzes energy industry trends; cost, price, and performance trends; market and policy drivers; and future outlooks to identify opportunities and challenges to manufacturing. NLR analyses enable geothermal energy and cross-technology insights that affect manufacturing cost and location decisions. These analyses can identify potential for increased domestic manufacturing of geothermal technologies in the United States.

Capabilities

- Identification of current and prospective global supply chains and trade flows of materials and components necessary for the manufacture of geothermal energy technologies

- Detailed manufacturing costs analysis, including the total costs of products manufactured in the United States relative to regions around the world

- Determination of the drivers of costs and the sensitivity of those drivers to technical and market inputs

- Identification of qualitative factors—such as intellectual property ownership and protection, opportunities for automation and advanced manufacturing, supporting infrastructure impacts, and trade restrictions—and their role in determining the location of new manufacturing facilities

- Manufacturing techno-economic analysis

Manufacturing Cost Analysis

NLR analysts develop bottom-up manufacturing cost models that consider materials, manufacturing steps and equipment, and assembly of subcomponents. The models include the machining cost of key and high-value components in geothermal power plant turbines—such as turbine blades, impellers, and shafts—by using Design for Manufacture and Assembly software. We produce detailed projected costs based on the volume of materials needed, the machines and process steps, machine setup time, and tooling. The manufacturing cost is not limited to the power plant turbine component; it can also be applied to other important components, such as heat exchangers, air-cooled condensers, and even high-temperature drilling tools.

Manufacturing Techno-Economic Analysis

NLR's discounted cash flow is a detailed financial model that provides the framework for deriving the minimum price for each product. Within the discounted cash flow, we can account for several considerations for manufacturing, such as capital cost; fixed operating costs (labor, depreciation, inflation and taxes, insurance, and rent); typical sales, general, and administrative expenses; and typical design and engineering cost.

NLR's U.S. capital assets pricing model is used to derive these debt and equity ratios and weight them by their relative contribution to the overall capital structure of the firm to estimate weighted average cost of capital values.

Publications

2018 Research Highlight in Manufacturing Analysis: Global Value Chain and Manufacturing Analysis on Geothermal Power Plant Turbines, NLR Brochure (2018)

Global Value Chain and Manufacturing Analysis on Geothermal Power Plant Turbines, NLR Technical Report (2018)

View all NLR publications about geothermal research.

Contact

Share

Last Updated Dec. 7, 2025