Thermochemical Conversion Techno-Economic Analysis

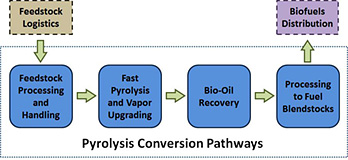

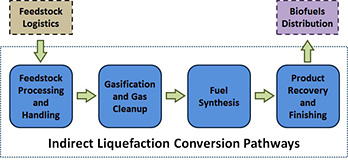

NREL's Thermochemical Conversion Analysis team focuses on the conceptual process design and techno-economic analysis (TEA) for the thermochemical conversion of biomass to fuels and products via direct liquefaction pathways, using pyrolysis or bio-oil intermediates, and indirect liquefaction pathways, using gasification or gaseous intermediates, from lignocellulosic biomass.

The primary objective of the Thermochemical Conversion Analysis effort is to support the Department of Energy Bioenergy Technologies Office's goal to help research technologies that will enable the production of cost-competitive hydrocarbon fuels from biomass. The conceptual process designs, detailed process models, and TEA developed under this project provide insights into the potential economic viability of biomass conversion process technologies currently in the research and development stage.

Featured Publications

Conceptual Process Design and Techno-Economic Assessment of Ex Situ Catalytic Fast Pyrolysis of Biomass: A Fixed Bed Reactor Implementation Scenario for Future Feasibility, Topics in Catalysis (2015)

Conceptual Process Design and Economics for the Production of High-Octane Gasoline Blendstock via Indirect Liquefaction of Biomass through Methanol/Dimethyl Ether Intermediates, Biofuels, Bioproducts and Biorefining (2015)

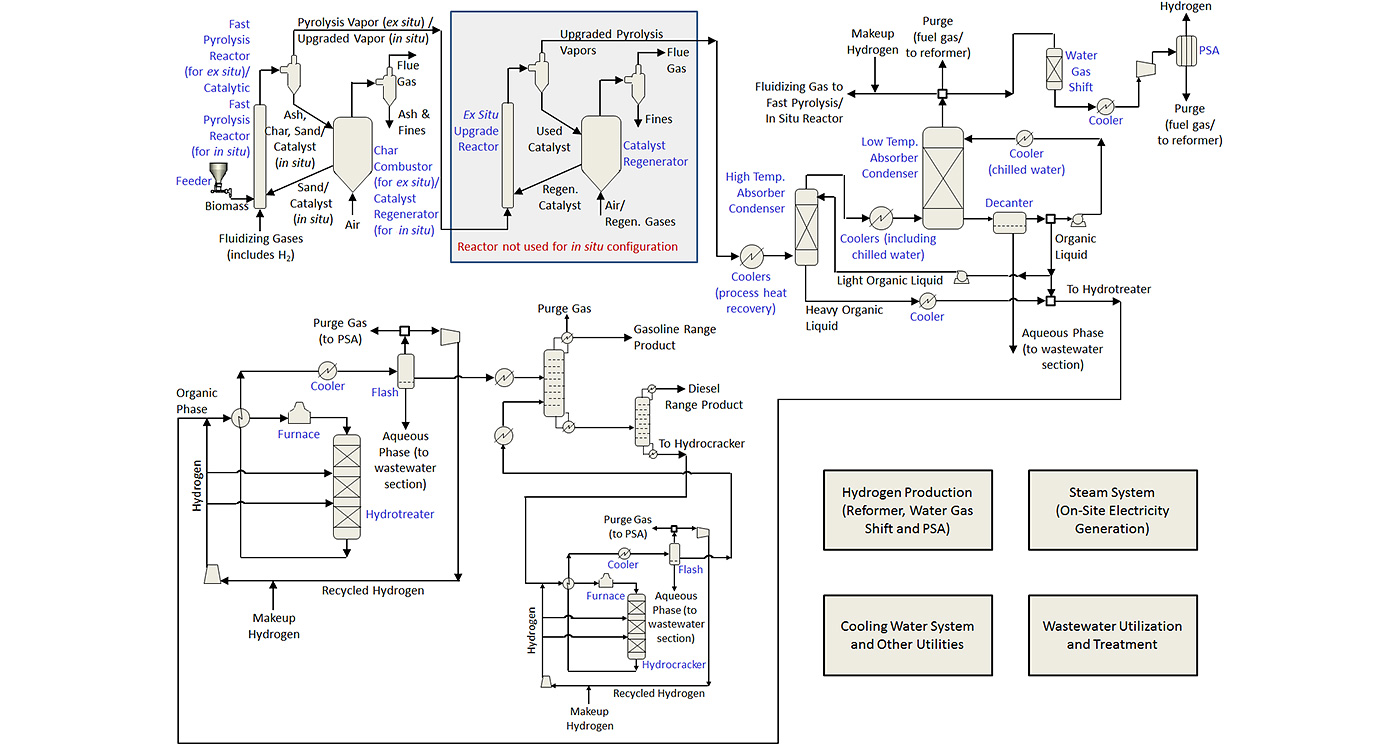

Process Design and Economics for the Conversion of Lignocellulosic Biomass to Hydrocarbon Fuels: Thermochemical Research Pathways with In Situ and Ex Situ Upgrading of Fast Pyrolysis Vapors, NREL/PNNL Technical Report (2015)

Process Design and Economics for the Conversion of Lignocellulosic Biomass to Hydrocarbons via Indirect Liquefaction: Thermochemical Research Pathway to High-Octane Gasoline Blendstock Through Methanol/Dimethyl Ether Intermediates, NREL/PNNL Technical Report (2015)

View all NREL thermochemical conversion techno-economic analysis publications.

Capabilities

Techno-economic analyses are performed to determine the potential economic viability of process technologies in the research and development stage. Evaluating the production costs of a given process technology, based on current performance and targets established for process improvements though research efforts, allows the analysis team to assess the potential economic feasibility of a process configuration. Results of these analyses are useful in determining which emerging technologies have the highest potential for near-, mid-, and long-term deployment success.

Conceptual process designs and detailed process models developed for TEA under this project allow the analysis team to evaluate aspects of process technology development like production costs, product qualities, heat integration, process optimization, and scale-up. The analysis team also assists the research efforts by helping establish technical targets for the research programs and quantifying the economic impact from research achievements. This helps direct research in the most impactful directions, with a goal of maturing towards commercial deployment. Sustainability metrics associated with the conversion processes are also tracked.

Within the Thermochemical Conversion Analysis project, there are currently two primary integrated conversion platforms under development, one based on pyrolysis of biomass to produce an oxygenated bio-oil intermediate (pyrolysis pathway analysis) and one based on the gasification of biomass to synthesis gas intermediate (indirect liquefaction pathway analysis).

Pyrolysis Pathway Analysis

Pyrolysis, direct liquefaction or bio-oil intermediate pathways R&D focuses on developing commercially viable technologies for converting biomass into energy-dense, fungible finished liquid fuels, such as renewable gasoline, jet, and diesel, as well as bioproducts and bioenergy. Current areas of research and analysis at NREL focus on catalyst development, bio-oil yield improvements, hydrodeoxygenation, maximizing production of diesel-range products, product quality relative to target fuels, process integration and optimization, and scale-up from bench to pilot scale.

Indirect Liquefaction Pathway Analysis

Gasification, indirect liquefaction or gaseous intermediates/syngas pathways R&D focuses on developing technology that converts biomass to a gaseous intermediate (e.g., synthesis gas, synthetic natural gas, or other mixed oxygenates) for the production of fuels, chemicals, and power. Current areas of research and analysis at NREL focus on catalyst development, increasing selectivity to desired products, coupling of olefins to produce jet- and/or diesel-range products, generating premium fuel blendstocks, process integration and optimization, and scale-up from bench to pilot scale.

Research Team

Principal Investigators

Engineers

Arpit Bhatt

Yanan Zhang

Related and Integrated Programs

Bioenergy Sustainability Analysis

Share