Strategic and Market Analysis

NREL works to develop analytical tools, methodologies, and systematic studies to understand the potential impact and critical barriers of the emerging bioeconomy.

Featured Publications

Lignin Valorization: Improving Lignin Processing in the Biorefinery, Science (2014)

The Feasibility of Producing and Using Biomass-Based Diesel and Jet Fuel in the United States, NREL Technical Report (2013)

Catalytic Upgrading of Sugars to Hydrocarbons Technology Pathway, NREL/PNNL Technical Report (2013)

View all NREL market and strategic analysis publications.

Capabilities

Market Assessment for Bioproducts Development

Production of chemicals from biomass offers a promising opportunity to reduce the U.S. dependence on imported oil, and to improve the overall economics and sustainability of an integrated biorefinery. Recent analysis projects the market share of bio-based chemicals in the global chemical industry to increase from 2% in 2008 to 22% by 2025, and the market potential for bio-based chemicals will reach $19.7 billion by 2016.

Given the increased momentum towards the deployment and scale-up of bioproducts, NREL is working to:

- Summarize near-term potential opportunities for growth in biomass-derived products.

- Identify the production leaders who are actively scaling up these chemical production routes.

- Review the consumers and market champions who are supporting these efforts.

- Understand the key drivers and challenges to moving biomass-derived chemicals to market.

- Evaluate the impact that the scale-up of chemical strategies will have on accelerating the production of biofuels.

Economics and Sustainability of Bio-Derived Jet Fuel

Aviation or jet fuel, a petroleum-based fuel used to power aircraft, has stricter quality requirements than fuels used in road transport. Biomass-derived jet (bio-jet) fuel has become a key element in the aviation industry's strategy to reduce operating costs and environmental impacts.

NREL's bioenergy analysis team is working with researchers from the oil-refining industry, the aviation industry, government, biofuel companies, agricultural organizations, and academia to develop a commercially viable and sustainable process that produces a renewable jet fuel with low production costs and low greenhouse gas emissions. This work is an example of our recent efforts in comparative techno-economic analysis.

Our analysis considers a wide range of conversion strategies from biochemical, thermochemical, and hybrid approaches for the production of jet fuel. We are evaluating both the current state of technology to target cases, as well as first-of-a kind plant estimates for these emerging technologies, and are identifying key data gaps and cost drivers critical for the success of these emerging pathways.

Refinery Integration of Bio-Derived Intermediates

NREL has developed first-of-its-kind process models and economic assessments of the co-processing of biomass-derived intermediates within an existing petroleum refinery. By leveraging existing refinery infrastructure, our goal is to drive down the cost of a standalone biorefinery by reducing both capital and operating costs. However, integration of biomass-derived intermediates is challenging. This work strives to understand the economic incentives, technical risks, and key data gaps that need to be addressed from a refiners perspective.

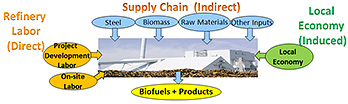

Jobs and Economic Development

Growth in the biofuels industry could create jobs not only through biorefinery construction, operation, and maintenance but also through feedstock production, processing, and transportation. Capturing the economic and social benefits resulting from the entire supply chain of biofuel production is a vital component to evaluate the sustainability of a new domestic bioenergy industry.

NREL has developed a suite of Jobs and Economic Development Impact (JEDI) models for selected hydrocarbon biofuels (e.g., gasoline and diesel blendstock from biomass via fast pyrolysis), ethanol production pathways from both lignocellulosic biomass and starch, biopower, and petroleum refinery processes. Learn more about and download the JEDI models.

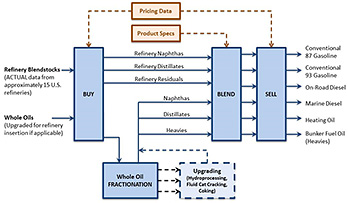

Blending Economics for Bio-Derived Hydrocarbons

The biofuel blending model is a detailed linear programming model that explores the potential for blending biomass-derived intermediates with petroleum-derived intermediates to meet finished fuel specifications. It uses tools that are consistent with the tools utilized by refineries to consider blending strategies to improve profitability. The overall objective of the blending model project is to (1) determine the amount of biomass-derived intermediates that can be blended into a gallon of gasoline and diesel, (2) assess the value of the biomass-derived hydrocarbons as gasoline and diesel blendstocks, and (3) identify the blending constraints for biomass-derived fuels.

Research Team

Principal Investigators

Related and Integrated Programs

Biochemical Conversion Techno-Economic Analysis

Bioenergy Sustainability Analysis

Thermochemical Conversion Techno-Economic Analysis

Collaborators

Argonne National Laboratory

Clean Energy Manufacturing Analysis Center

Oak Ridge National Laboratory

Pacific Northwest National Laboratory

Share