Algal Biofuels Techno-Economic Analysis

To promote an understanding of the challenges and opportunities unique to microalgae, NREL's Algae Techno-Economic Analysis group focuses on techno-economic analysis (TEA) for the production and conversion of algal biomass into biofuels and coproducts.

We help research technologies that will enable the production of cost-competitive hydrocarbon fuels and products from algal biomass in support of the goals of the U.S. Department of Energy's (DOE's) Bioenergy Technologies Office. Our conceptual designs provide insights into research priorities and key challenges with respect to process improvement, scale-up, and integration, and help to quantify the success criteria for continued algae research. The outcome of TEA modeling provides projected economics and algal biomass/fuel selling prices attributed to a hypothetical commercial-scale facility, and establishes benchmarks to assess the state of technology based on current research performance.

Featured Publications

Process Design and Economics for the Production of Algal Biomass: Algal Biomass Production in Open Pond Systems and Processing through Dewatering for Downstream Conversion, NREL Technical Report (2016)

The Potentials and Challenges of Algae Based Biofuels: A Review of the Techno-Economic, Life Cycle, and Resource Assessment Modeling, Bioresource Technology (2015)

Acid-catalyzed algal biomass pretreatment for integrated lipid and carbohydrate-based biofuels production, Green Chemistry (2015)

Process Design and Economics for the Conversion of Algal Biomass to Biofuels: Algal Biomass Fractionation to Lipid- and Carbohydrate-Derived Fuel Products, NREL Technical Report (2014)

Renewable Diesel from Algal Lipids: An Integrated Baseline for Cost, Emissions, and Resource Potential from a Harmonized Model, NREL/Argonne/PNNL Technical Report (2012)

View all NREL algal biofuels techno-economic analysis publications .

Capabilities

Techno-economic analyses are performed to determine the potential economic viability of process technologies in the research and development stage. Evaluating the production costs of a given process technology, based on current performance and targets established for process improvements though research efforts, allows the analysis team to assess the potential economic feasibility of a process configuration. Results of these analyses are useful in determining which emerging technologies have the highest potential for near-, mid-, and long-term deployment success.

Conceptual process designs and detailed process models developed for TEA under this project allow the analysis team to evaluate aspects of process technology development like production costs, product qualities, heat integration, process optimization, and scale-up. The analysis team also assists the research efforts by helping establish technical targets for the research programs and quantifying the economic impact from research achievements. This helps direct research in the most impactful directions, with a goal of maturing towards commercial deployment. Sustainability metrics associated with the conversion processes are also tracked.

Within the Algae TEA project, there are currently two primary process areas of focus considered through TEA modeling, namely production of algal biomass and conversion of algal biomass to fuels via "combined algal processing."

Algal Biomass Production Analysis

Production of fuels from microalgae has received renewed interest over recent years, due to the potential for achieving favorably high fuel yields from algal biomass (due in turn to potentially high carbon and energy content of algal biomass compared to terrestrial feedstocks), as well as high biomass yields from an acre of land (due in turn to potentially high photosynthetic efficiency of algal biomass), while exhibiting flexibility to grow on low-value land and water that does not need to compete with food or other biomass resources. However, algal processes also face unique challenges attributed to the aquatic nature of the biomass "farming" and processing logistics, as well as inherent seasonality fluctuations in biomass cultivation. The TEA work conducted under this project focuses on understanding these unique challenges and opportunities for microalgae, grounded in technical and financial constraints imposed by TEA.

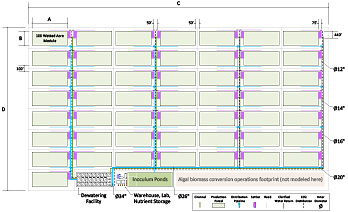

During this part of the analysis process, we focus on "algae farm" cultivation and processing logistics for the production of algal biomass and subsequent concentration to desirable levels for downstream conversion. This includes considerations for CO2 and nutrient sourcing/delivery, inoculation, primary cultivation, and dewatering. Historically TEA has considered cultivation in both open pond and closed photobioreactor systems. Isolating the TEA modeling efforts to this portion of the full process provides valuable insights as to key cost drivers and areas for potential improvement attributed to the production of algal biomass, which typically is the overwhelming cost driver in a fully-integrated "farm-to-fuel" processing supply chain due to both costly production systems and to lower downstream costs/high yields for subsequent biomass conversion to fuels.

Algal Biomass Conversion Analysis

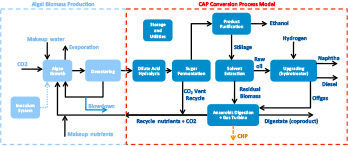

Our team analyzes the efficacy and research and development opportunities for a method of converting algal biomass referred to as the combined algal processing (CAP) pathway. In the process, dewatered (~20% solids) biomass is subjected to dilute acid pretreatment to non-destructively fractionate algal biomass by hydrolyzing carbohydrates into monomeric sugars, and to make the material amenable to downstream lipid extraction of the wet biomass without the need for energy-intensive drying. Liberated sugars may be fermented into a wide variety of products, including ethanol or hydrocarbon fuels, or chemical products such as organic acids, diols, or other hydrocarbons. Lipids are extracted to high yields using a solvent, and protein may be utilized in a number of ways including anaerobic digestion (for reuse of nutrients and heat/power production), sale as animal or fish feed, or further conversion to fuels or chemical replacements.

Rigorous TEA analysis of this portion of the process is important because, while less of a cost driver than upstream production of algal biomass, conversion of algal biomass via the CAP process is sensitive to biomass composition (carbohydrates, lipids, proteins, and other constituents), which may vary dramatically between algal strains, cultivation systems, and harvesting practices. As such, the CAP processing configuration and unit operations may be optimized to best capture the potential value of the given algal biomass for production of fuels and coproducts, to ultimately identify paths towards economic viability.

Research Team

Principal Investigators

Engineers

Related and Integrated Programs

Bioenergy Sustainability Analysis

Collaborators

Argonne National Laboratory

Idaho National Laboratory

Pacific Northwest National Laboratory

Share