Biogas Upgrading and Waste-to-Energy

NREL's waste-to-energy research seeks pathways to use waste feedstock to recover energy and produce fuels and chemicals.

We focus on resource assessment, techno-economic analysis, and the research and development required for upgrading biogas to fuels and high-value coproducts.

Featured Publications

Using Waste CO2 to Increase Ethanol Production from Corn Ethanol Biorefineries: Techno-Economic Analysis, Applied Energy (2020)

Upgrading Brown Grease for the Production of Biofuel Intermediates, Bioresource Technology Reports (2020)

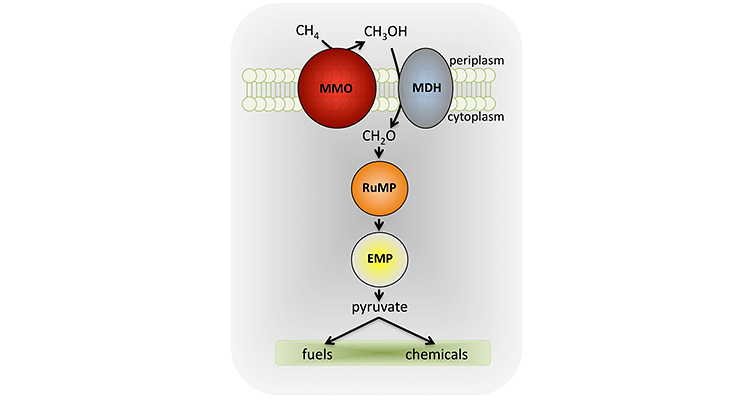

Muconic Acid Production from Methane Using Rationally-Engineered Methanotrophic Biocatalysts, Green Chemistry (2019)

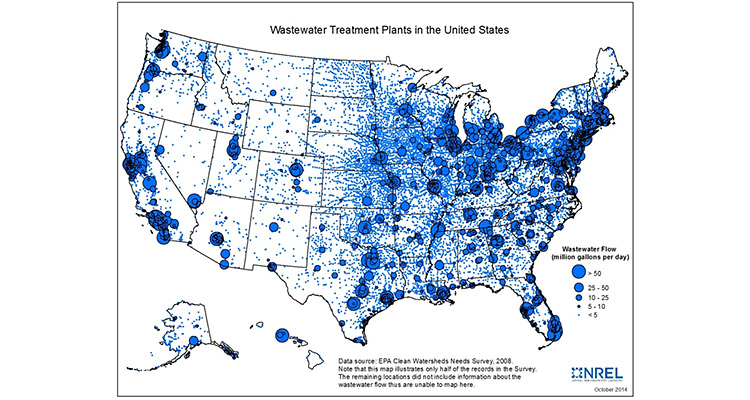

Wet Waste-to-Energy Resources in the United States, Resources, Conservation and Recycling (2018)

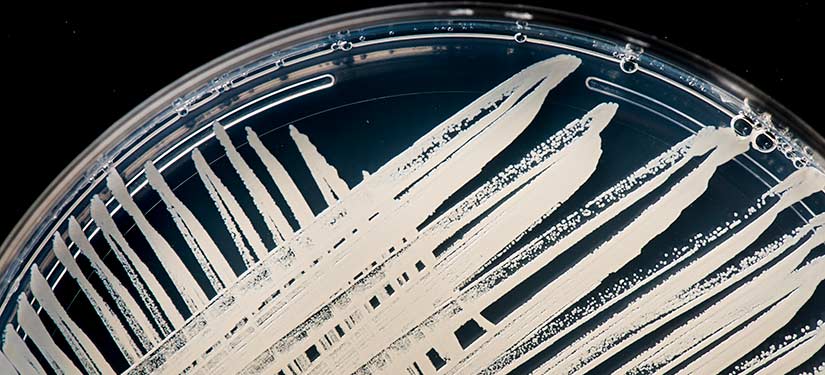

Biogas Biocatalysis: Methanotrophic Bacterial Cultivation, Metabolite Profiling, and Bioconversion to Lactic Acid, Frontiers in Microbiology (2018)

View all NREL biogas upgrading and waste-to-energy publications.

Waste-to-Energy Technical Assistance

To help advance waste to energy technologies, we offer technical assistance for local governments.

Methane Conversion to Liquid Fuels and Chemicals Using a Methanotrophic Biocatalyst

NREL is working to valorize biogas and natural gas through the development of biological methane upgrading strategies, targeting conversion of methane to liquid fuels and chemicals. Research activities for these multi-institutional projects encompass strain development, high-productivity gas fermentation process development, product recovery and upgrading, and techno-economic analysis.

Contact: Michael Guarnieri

Waste Feedstocks

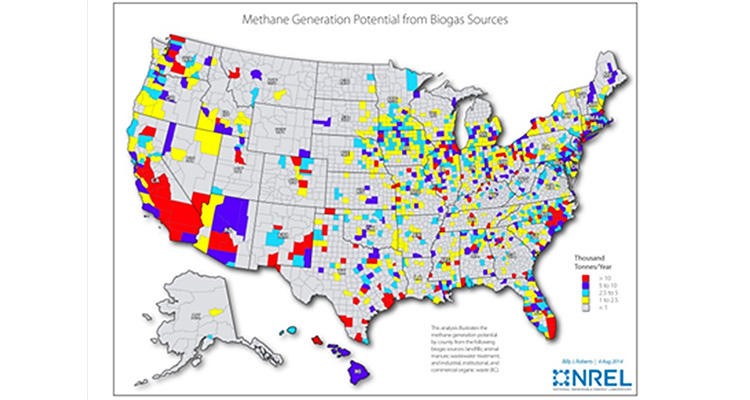

We inventory and analyze waste feedstocks—fats, oils, and greases; municipal solid waste including food waste, plastics, and wood; wastewater sludge; animal manure; biorefinery residues and biogas—and work to address feedstock data gaps, inventory feedstock characteristics, map their geographic distribution, and estimate the market and energy potential from these resources.

Contact: Anelia Milbrandt

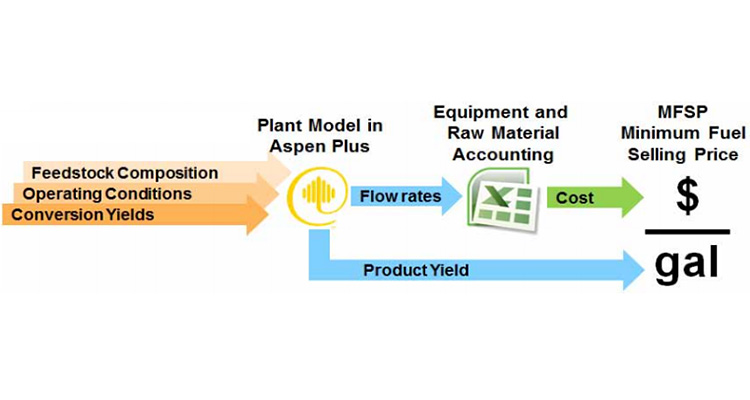

Waste-to-Energy Techno-Economic Analysis

We perform techno-economic analysis for converting waste feedstocks to power, fuels, and bioproducts to compare different conversion pathways for utilizing waste materials, as well as to support the renewable energy mission, provide economic variability, environmental sustainability, and support decision-making at different levels.

Contact: Ling Tao

Waste-to-Energy System Simulation Model

NREL's waste-to-energy system simulation model is designed to develop and analyze scenarios that explore the evolution of the waste-to-energy industry and determine how waste-to-energy fuel technologies may be deployed in such a way that they make a significant contribution to the country's transportation energy.

Contact: Danny Inman

Research Team

Principal Investigators

Engineers

Kevin Harrison

Scientists

Related and Integrated Programs

Waste to Energy Combustion, Gasification, and Anaerobic Digestion On-Site Evaluation

Collaborators

Argonne National Laboratory (Life-Cycle and Sustainability Analysis)

Farmatic Inc.

Johnson Matthey

LanzaTech

Metabolon Inc.

North Carolina State University

Pacific Northwest National Laboratory (Analysis and Sustainability Interface)

San Diego State University

University of North Dakota Energy and Environmental Research Center (EERC) with Lockheed Martin (Strategic Environmental Research and Development Program projects, PI Kim Magrini)

University of Washington

This program is funded in part by the U.S. Department of Energy's Bioenergy Technologies Office.

Share