Thermochemical Process Integration, Scale-Up, and Piloting

Our mission is to integrate, scale-up, and demonstrate biomass conversion technologies developed at the laboratory scale to an industrially relevant pilot scale.

Variety of Pathways

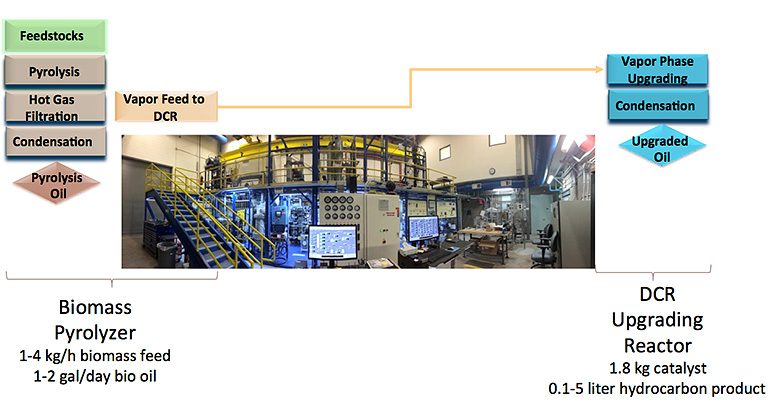

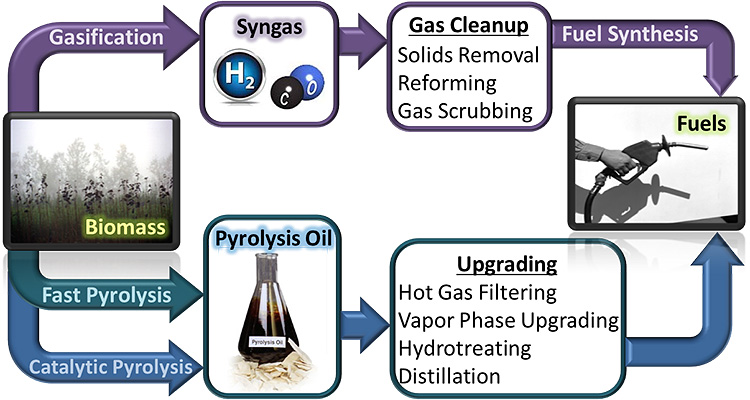

Our pilot-scale systems are capable of testing multiple biomass-to-fuels and chemical pathways including gasification, fast pyrolysis, catalytic fast pyrolysis, and vapor phase upgrading. Our systems are flexible, allowing for modifications based on new technologies and research areas. To learn more about our systems, see Thermal and Catalytic Process Development Unit.

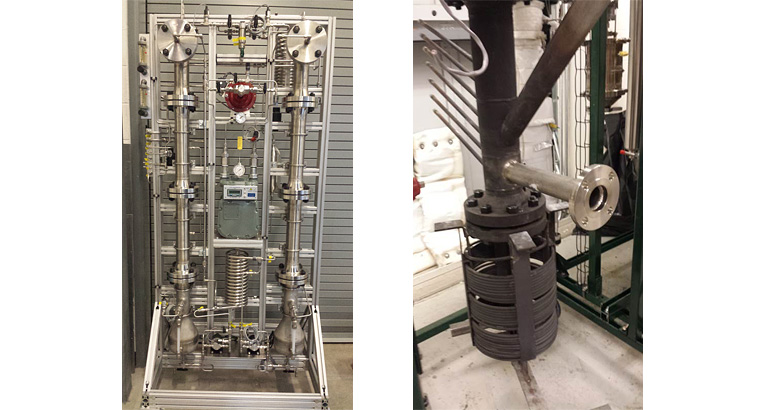

Engineering and Scaled Design

Our engineers work with researchers, consultants, and partners to design reactors and other unit operations to overcome scaling effects and provide innovative solutions. Using our pilot-scale facilities, we can install and test the designs under real operating conditions.

Technology Demonstrations

We demonstrate the current state-of-technology at the pilot scale and provide operational data for use in techno-economic analysis. In 2017, we will demonstrate three thermochemical pathways: (1) syngas upgrading to high-octane fuels and fuel additives, (2) fast pyrolysis followed by hydrotreating, and (3) pyrolysis vapor phase upgrading.

Technology Integration

We work closely with the lab-scale researchers to integrate their work together and provide real-world testing conditions for their feedstock, catalyst, and other discoveries. Data collected from pilot-scale testing is then provided back to the lab-scale research to inform future developments.

Research Team

Principal Investigators

Stuart Black

Ray Hansen

Matt Oliver

Kellene Orton

Scott Palmer

Brady Peterson

Marc Pomeroy

Mike Sprague

Alex Stanton

Rebecca Jackson

Related and Integrated Programs

Collaborators

BP

Equilibrium Catalysts

Idaho National Laboratory

Johnson Matthey

Nexceris

Pacific Northwest National Laboratory

Particulate Solid Research Inc.

Springs Fabrication

WR Grace

Zeton

Share