Biomass Feedstocks

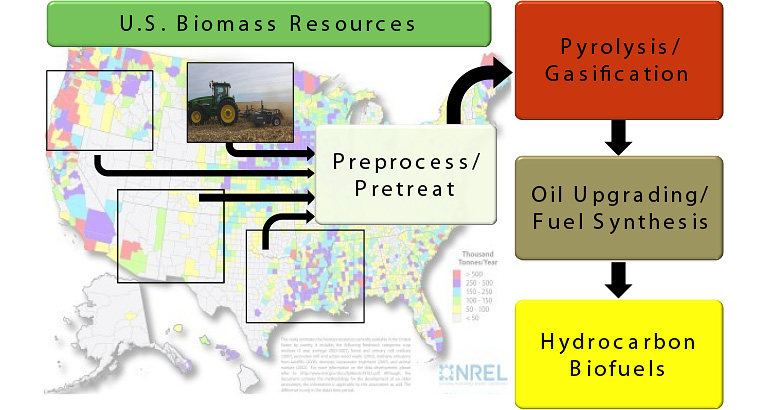

Our mission is to enable the coordinated development of biomass resources and conversion technologies by understanding the field-to-fuel impact of feedstocks on biochemical and thermochemical processes.

View all NREL biomass feedstock publications.

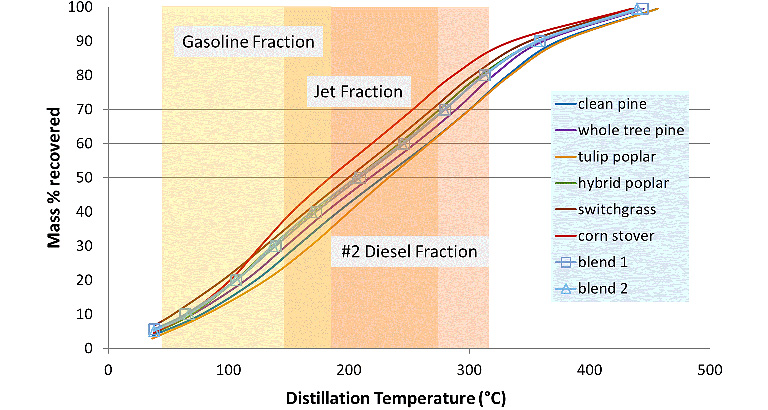

Thermochemical Feedstock Performance Testing

We evaluate the "field-to-fuel" performance of industrially relevant feedstocks and blends in thermochemical processes, such as fast pyrolysis, catalytic fast pyrolysis, and gasification, and assess the impact of various feed preprocessing technologies.

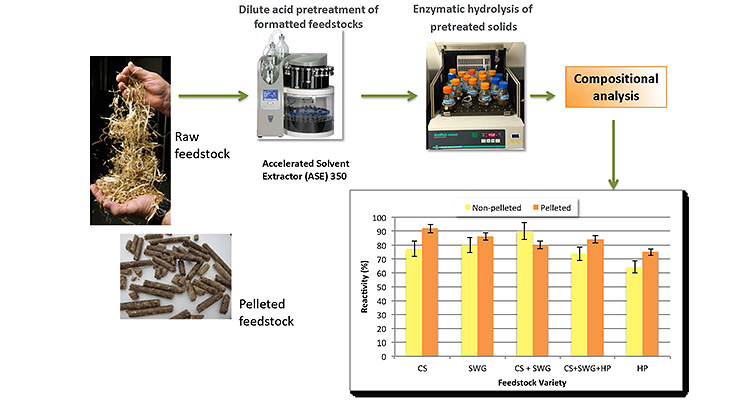

Bioconversion Characterization and Performance Testing

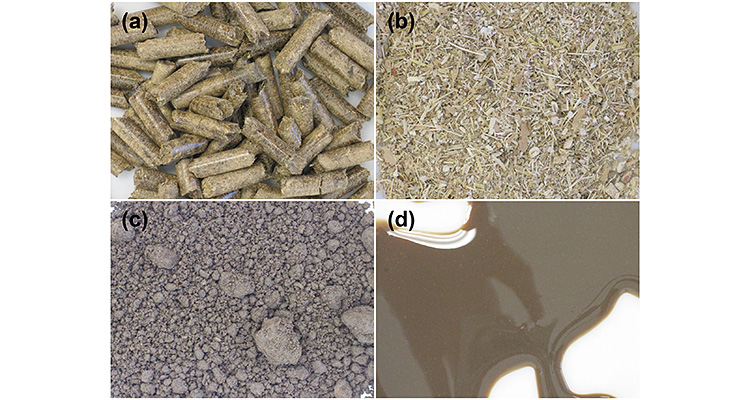

We investigate how various types of native and formatted biomass feedstocks, such as the densified and/or blended feedstocks shown in the image, impact the bioconversion, and ultimately the production, of fuels and chemicals needed for a growing economy.

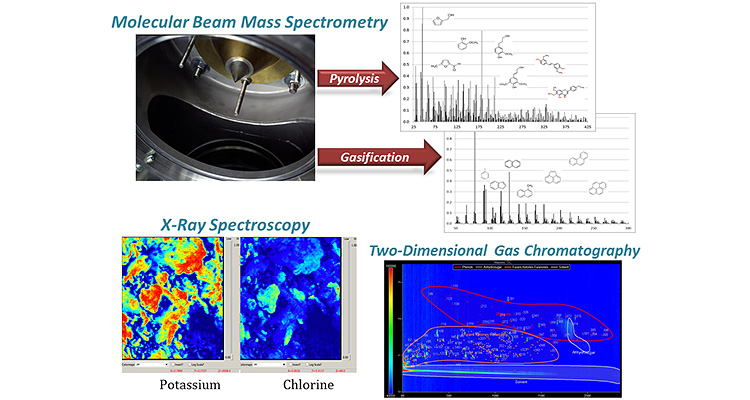

Advanced Feedstock and Product Characterization

We are using advanced analytics to characterize biomass and its thermochemical products, including molecular beam mass spectrometry, x-ray spectroscopy, near-infrared spectroscopy, 2-D gas chromatography, and high-resolution mass spectrometry. Learn more about biomass characterization research at NREL.

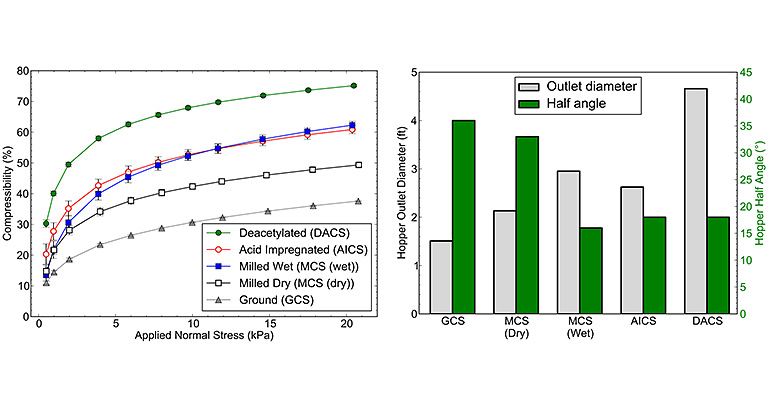

Biomass Rheology and Flowability Characterization

We utilize rheological characterization and granular solids flow testing to better understand how physical, chemical, and biological processing impact biomass feeding and handling throughout the biorefinery.

Research Team

Principal Investigators

Ed Wolfrum

Principal Researcher and Manager, Process and Analytical Engineering Group

Ed.Wolfrum@nrel.gov303-384-7705

Stuart Black

Earl Christensen

Steve Deutch

Nathaniel Crawford

Kellene McKinney

Michele Nolker

Scott Palmer

Braden Peterson

Kailee Potter

Jeff Wolfe

David Lee

Related and Integrated Programs

Biochemical Process Development and Integration

Thermochemical Process Integration, Scale-Up and Piloting

Collaborators

C3Bio

Colorado State University

Energy Technology Centre (Sweden)

Idaho National Laboratory

International Energy Agency

Massachusetts Institute of Technology

North Carolina State University

Pacific Northwest National Laboratory

U.S. Department of Agriculture

Washington State University

The Biomass Feedstocks R&D program acknowledges funding and support from the U.S. Department of Energy's Bioenergy Technologies Office.

Share