Biomass Deconstruction and Pretreatment

Our mission is to transform lignocellulose into intermediate streams with low toxicity, high sugar concentrations, and utilizable lignin for biological and thermochemical upgrading to fuels and products with minimal waste generation and material and energy use.

Chemical Deconstruction

We develop alkali, acid, and oxidative-based chemical deconstruction processes that result in intermediate streams tailored to specific biochemical and catalytic upgrading strategies.

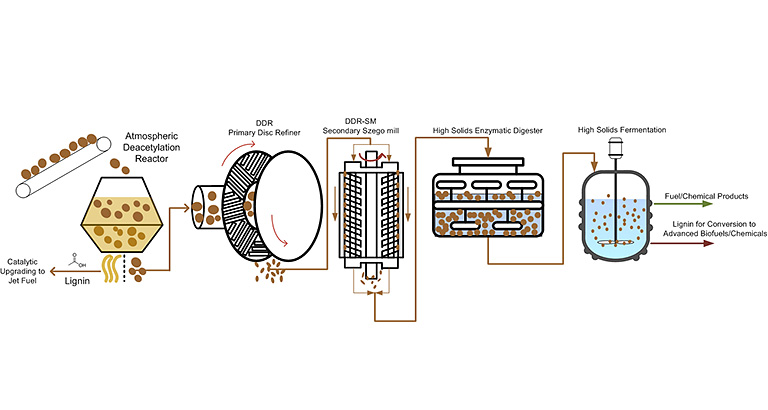

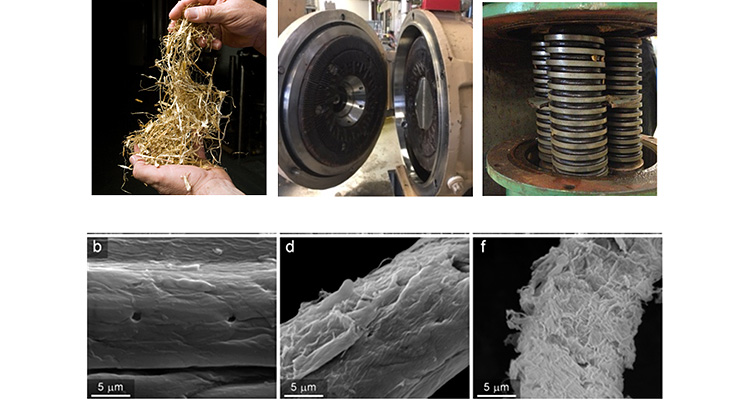

Mechanical Deconstruction

Integrated chemical and mechanical deconstruction strategies, such as the NREL deacetylation and mechanical refining (DMR) process, result in low-toxicity, high-concentration sugar streams and native-like lignin following enzymatic hydrolysis.

Enzymatic Deconstruction

After chemical and/or mechanical deconstruction, an enzymatic hydrolysis is performed to convert biomass polysaccharides into their monomeric sub-units for biological fermentation and/or catalytic upgrading.

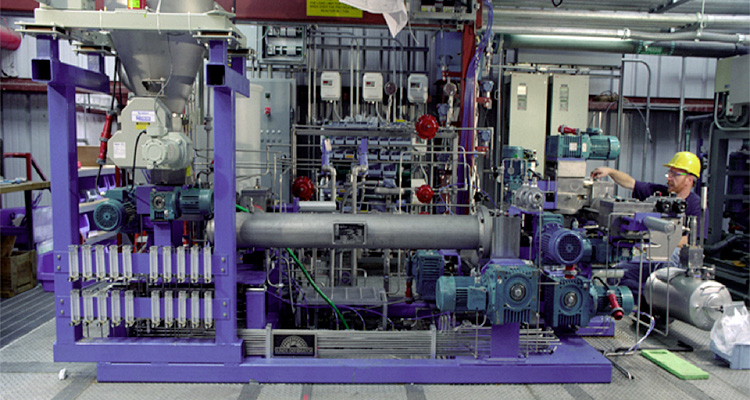

Equipment and Capabilities

The majority of the pretreatment and biomass deconstruction equipment is located in the NREL Integrated Biorefinery Research Facility (IBRF).

Research Team

Principal Investigators

Lintao Bu

Rui Katahira

Ali Mohagheghi

Kailee Potter

Holly Smith

Larry Taylor

Thieny Trinh

Nate Crawford

Bill Bray

Wes Hjelm

Bob Lyons

Leslee Pohlee

Related and Integrated Programs

Biochemical Conversion Techno-Economic Analysis

Biochemical Process Development and Integration

Biological and Catalytic Conversion of Sugars and Lignin

Collaborators

Abengoa

ADM

Amyris

Cargill

Codexis

DSM

DuPont

Ecopetrol

Green Earth Institute

Idaho National Laboratory

JGC

MBG

Novozymes

North Carolina State University

Pacific Northwest National Laboratory

Poet

Toyota

University of North Dakota

Virent

Washington State University

Share