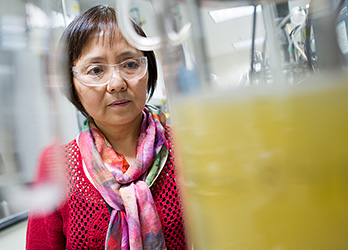

Enzyme and Microbial Development

NREL's enzyme and microbial development researchers improve the performance of enzymes and microbes for fuels and chemicals production from a variety of biomass feedstocks.

In the process, we employ physical chemistry, biochemistry, computational modeling, and synthetic biology.

Featured Publications

Revealing Nature's Cellulase Diversity: The hyperactive CelA from Caldicellulosiruptor bescii, Science (2013)

How Does Plant Cell Wall Nanoscale Architecture Correlate With Enzymatic Digestibility?, Science (2012)

Biomass Recalcitrance: Engineering Plants and Enzymes for Biofuels Production, Science (2007)

View all NREL enzyme and microbe development publications

Capabilities

Feedstocks

We test multiple biomass feedstocks with the standard and exploratory process of pretreatment, enzyme hydrolysis, and microbial conversion.

Microbes

Our microbial menagerie spans from hyperthermophilic bacteria to industrial filamentous fungi and yeast, as well as unique eukaryotic cellulose degraders such as social amoebae and aquatic crustaceans.

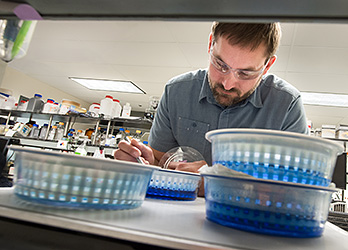

Biochemistry

Leveraging our expertise in protein structure/function, physical chemistry, enzyme kinetics, discovery, crystallography, and characterization, we engineer enzymes both for biomass hydrolysis and metabolic pathway improvement.

Bio-Products

We combine metabolic pathway engineering with chemical catalysis to generate a variety of biofuels, biochemicals, and bio-materials.

Systems Biology

We use molecular biology, protein characterization, proteomics, and HTP screening to improve enzyme function and metabolic flux as well as create new metabolic pathways. We also improve feedstocks through engineering cell wall components and expressing enzymes in muro to enable more efficient hydrolysis.

Research Team

Principal Investigators

John O. Baker

Daehwan Chung

Larry Taylor

Todd Vander Wall

Qi Xu

John Michael Yarbrough

Chien-Yuan Lin

Rouran Zhang

Todd Shollenberger

Related and Integrated Programs

Microbial Development and Metabolic Engineering

Collaborators

BioEnergy Sciences Center

C3Bio

Novozymes

Oak Ridge National Laboratory

Purdue University

University of Colorado, Boulder

Weizmann Research Institute

Share