Katie Gaston

Researcher IV-Chemical Engineering

Katherine.Gaston@nrel.gov

303-384-6273

https://orcid.org/0000-0002-1162-0905

https://orcid.org/0000-0002-1162-0905

Google Scholar

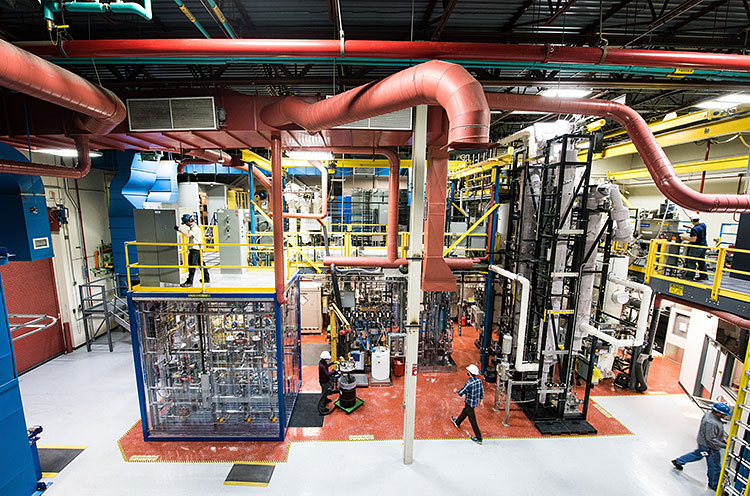

NREL’s Thermal and Catalytic Process Development Unit can process 1/2 ton per day of biomass via fast pyrolysis or steam gasification. The new catalytic riser reactor system can be used for ex situ vapor-phase upgrading or steam reforming with continuous catalyst regeneration. Get more information about NREL’s Thermochemical Processes.

Research Interests

-

Biomass fast pyrolysis including catalytic upgrading

-

Biomass gasification and catalytic gas cleanup

-

Fluidized beds and circulating fluidized beds

-

Unit operations associated with thermochemical and catalytic conversion of biomass

-

Pilot plant design, operations, and optimization

Affiliated Research Programs

-

Computational Modeling (Collaborator)

-

Feedstock-Conversion Interface Consortium (Contributor)

-

Heterogeneous Catalysis for Thermochemical Conversion (Collaborator)

-

Thermochemical Conversion Techno-Economic Analysis (Collaborator)

-

Thermochemical Process Integration, Scale-Up, and Piloting (Contributor)

Areas of Expertise

Katherine has worked as a chemical process and controls engineer in the Thermal and Catalytic Process Development Unit at the National Renewable Energy Laboratory (NREL) since 2007, focusing on safe, pilot-scale research of various technologies that enable renewable biomass to be converted to liquid fuels and chemicals. Her expertise includes:

-

Pilot-scale process design, installation, and startup

-

Design, installation, and programming of instrumentation and control systems

-

Pilot-plant experiment planning and operations

-

Data analysis and reporting

-

Process optimization

-

Process equipment design

-

Process safety management, management of change, process hazard analysis (PHA) and hazard and operability analysis (HAZOP), and layers of protection with regard to engineering controls

Education

- BChE, University of Delaware, 1997

Professional Experience

-

Chemical Process & Controls Engineer, NREL, 2007–present

-

Controls Engineer, Applied Control Engineering, 2000–2006

-

Process Engineer, National Starch and Chemical, 1997–1999

Featured Publications

-

"Pilot Scale Production of Mixed Alcohols from Wood," Industrial & Engineering Chemistry Research (2014)

-

"Biomass pyrolysis and gasification of varying particle sizes in a fluidized-bed reactor," Energy & Fuels (2011)

-

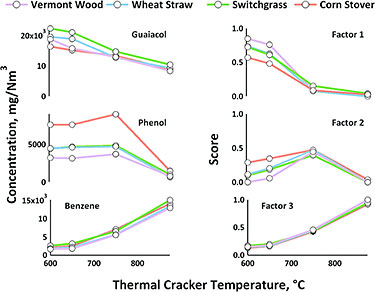

"Pilot-Scale Gasification of Corn Stover, Switchgrass, Wheat Straw, and Wood: 1. Parametric Study and Comparison with Literature," Industrial & Engineering Chemistry Research (2010)

-

"Pilot-Scale Gasification of Corn Stover, Switchgrass, Wheat Straw, and Wood: 2. Identification of Global Chemistry Using Multivariate Curve Resolution Techniques," Industrial & Engineering Chemistry Research (2009)

Please contact me with research questions, ideas for collaborations, and questions about projects related to my research interests at NREL. Please do NOT contact me directly for jobs—see instead information on NREL's Director's Postdoctoral Fellowship program or on NREL Careers in general.

Share