Renewable Energy Is Green, but We Can Make It Greener

NREL’s Code-Based Life Cycle Assessments Confront Environmental Impacts of Renewable Energy Technologies From Cradle to Grave

The U.S. energy transition is gaining speed, accelerated by government renewable energy goals and billions of dollars through the Inflation Reduction Act. As we race toward a greener future, understanding the potential adverse effects of renewable energy technologies before they are deployed has never been more critical.

Dozens of researchers at the National Renewable Energy Laboratory (NREL) have spent decades studying the life cycles and environmental impacts of renewable energy technologies. This work—called life cycle assessment—is crucial for making sure energy technologies are as clean as they can be.

"A lot of what we do at NREL is designed to make the world better through cheaper, cleaner, more equitable, sustainable energy," said Rebecca Hanes, a researcher in NREL's Strategic Energy Analysis Center (SEAC), where most of the laboratory's life cycle assessment work takes place. "But we're also making sure energy technologies are not causing unintended consequences. By looking at the entire supply chain, we can determine if there are ways to lessen the impacts of these technologies."

Three Life Cycle Phases of Renewable Energy Technologies

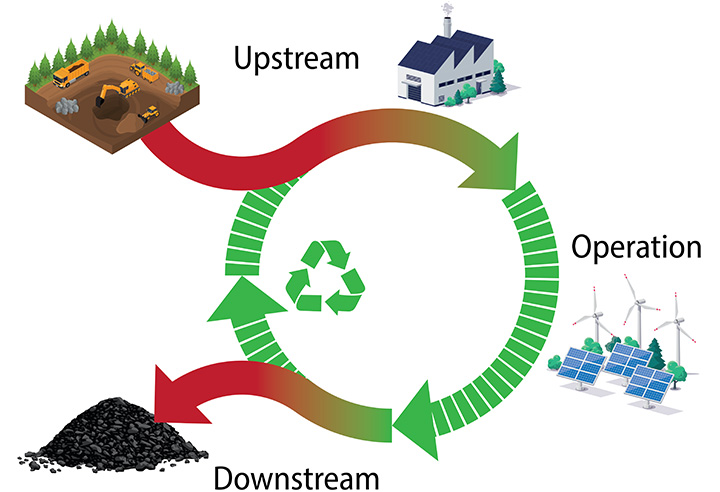

Life cycle assessment uses a "cradle-to-grave" evaluation of the environmental impacts of a product over three phases of its life:

- Upstream: Resource extraction, component and product manufacturing, and related transportation

- Operation: Product use and maintenance

- Downstream: Dismantling, decommissioning, and disposing or recycling at the end of the product's life.

Because renewable energy technologies like wind or solar do not produce emissions during use, most of their environmental impacts occur before and after operation. Life cycle assessment can track manufacturing materials and processes, model supply chain impacts, and evaluate circular economy strategies. These data can inform decisions about research, design, development, and deployment of renewable energy technologies.

For renewables, there's a heavy emphasis in life cycle assessment on the burdens coming from upstream—where materials are taken from the earth, processed, and manufactured into components that are then manufactured into full technologies.

— SEAC researcher Garvin Heath, who co-led the Life Cycle Assessment Harmonization Project, one of the first efforts at harmonizing life cycle assessment methods, data, and assumptions across studies.

A Niche in Code

Typically, life cycle assessment practitioners evaluate the phases of a product's life cycle using specific, fixed assumptions around inputs such as the type of power used. Often these assessments are conducted using software with graphical user interfaces that require each change to be done manually. However, with increasing interest in assessing technologies across changing conditions, NREL has shifted to more novel and scalable methods.

NREL is the only U.S. Department of Energy (DOE) national laboratory with a dedicated team of researchers working in code-based life cycle assessment, which scales traditional life cycle assessment to accommodate greater amounts of life cycle data, processes, and technologies. This approach creates a more comprehensive picture of a technology's impact across time and location.

"While code-based life cycle assessment encompasses all the methods and standards of typical, process-based life cycle assessment, it has the added benefit of automation," said SEAC researcher Patrick Lamers, who has spearheaded NREL's code-based life cycle assessment work. "We can now automatically account for system dynamics, like a changing economy or power sector, and we can do this over a series of environmental impacts and resource-use metrics at the same time."

A few years ago, he encouraged researchers within SEAC's life cycle assessment community of practice to go all-in on code-based life cycle assessment. The team needed a more comprehensive way to help NREL's primary client, DOE, make informed and equitable decisions on long-term renewable energy investments, ideally preemptively addressing possible adverse side effects for the environment and society.

Since Lamers launched the effort, NREL's code-based life cycle assessment practice has taken off.

"Once we saw what code-based life cycle assessment is capable of, more and more of my SEAC colleagues tried it out within their projects," he said. "Our work on code-based life cycle assessment is one of the most rewarding achievements of my career. What began as an idea led to a team of funded and highly motivated people working in a space where clients and NREL leadership are seeing huge value."

NREL's code-based life cycle assessment uses an open-source Python library that was originally created by researchers at the Swiss Federal Institute of Technology Zurich and the Paul Scherrer Institute. NREL is now collaborating with these researchers across several projects designed to advance open-source life cycle assessment code and data sets and to make them accessible to a larger community of users across the world.

"This work includes years of relationship building with the Swiss entities, now our partners—making NREL a front-runner in code-based life cycle assessment both internationally and within the DOE laboratory system," Lamers said.

Present-Day Technologies at Scale, in a Future Context

Code-based life cycle assessment uses spatial data sets that enable users to directly compare different technologies over time, space, and specific metrics. Following are two examples of this type of code-based life cycle assessment work.

- Evaluating two promising direct air capture technologies across a series of climate

change mitigation scenarios while considering structural changes of the power sector:

Results of this work revealed that electricity sector decarbonization and direct air capture technologies are both indispensable to avoid environmental problem shifting (that is, when solving one environmental problem, another emerges). Decarbonizing the electricity sector improves carbon storage efficiency, but the environmental impact of direct air capture varies across regions, highlighting the importance of smart energy-system siting and integration. - Comparing two power-to-hydrogen technologies across a series of future decarbonization

scenarios while accounting for structural changes in the cement, steel, fuel, and

power sectors:

In this study, researchers deciphered the nonlinear relationships between future technology and energy system dynamics over time and determined which of these changes had the strongest influence on the technology's environmental impacts.

NREL researchers have also linked their life cycle assessments to NREL flagship tools, such as the Regional Energy Deployment System (ReEDS), which simulates the evolution of the bulk power system from present day through 2050 or later. By integrating with tools like ReEDS, NREL can assess a technology in any region of the future U.S. power system over time. An example of this type of analysis showed that closed-loop pumped storage hydropower systems are the most climate-friendly method for storing energy when accounting for the full impacts of materials, construction, operation, maintenance, and decommissioning over the systems' assumed 80-year lifetime.

The Future of NREL's Code-Based Life Cycle Assessment

Another leading NREL figure in this space is Tapajyoti "TJ" Ghosh, who has been working side by side with Lamers over the past three years.

"Code-based life cycle assessment represents a tectonic shift in the way we analyze renewable energy technology materials, processes, and impacts," Ghosh said. "By moving to a code-based platform that utilizes NREL's high-performance computer, we can reveal a wealth of insights that would have taken us much longer to achieve in any other fashion."

Lamers and Ghosh predict that in five years, all of NREL's core life cycle assessment work will be code based. They are actively working on several open-source prospective life cycle assessment tools, enabling the analysis of new technologies under projected energy, economy, land, and/or climate scenarios. The tools share the same platform—the Life-cycle Assessment Integration into Scalable Open-source Numerical models (LiAISON)—yet allow for single or multisector dynamics, such as changing the regional energy or electricity mix (e.g., LiAISON-ReEDS) or larger climate and economic contexts (e.g., LiAISON-Global Change Analysis Model [GCAM]).

"Code-based life cycle assessment provides the platform that's needed to assess present-day technologies at scale in a future context," Lamers said. "It also ensures that we can make investment decisions in renewable energy technology options today more confidently, knowing that we have evaluated possible trade-offs of such technologies across the various possible system contexts of tomorrow."

NREL has developed a variety of life cycle assessment tools that provide industry practitioners, lenders, utility executives, and lawmakers with the best information about greenhouse gas emissions from various sources of energy.

Cambium: An annually updated, publicly available data set, Cambium includes modeled hourly emission, cost, and operational metrics for a range of possible futures of the U.S. electricity sector through 2050. Cambium helps answer life cycle assessment questions about the transition to more reliable, resilient, low-carbon power systems, enabling better decisions by the people planning the grid and grid-connected systems.

Circular Economy Lifecycle Assessment and Visualization (CELAVI): This code-based circular supply chain simulator models the impacts of renewable energy supply chains as they transition toward circularity by reusing, recycling, and upcycling materials, resulting in environmental, social, and economic benefits or drawbacks. In addition to incorporating life cycle assessment, CELAVI also breaks down environmental impacts by materials and processes over time and space.

LiAISON: An open-source, prospective life cycle assessment framework, Life-cycle Assessment Integration into Scalable Open-source Numerical models (LiAISON) enables the life cycle analysis of present-day new technologies under different future energy-economy-land-climate system contexts. This enables the assessment of novel technologies at scale in various contexts to preemptively evaluate potential trade-offs over metrics, time, and regions.

Materials Flows through Industry (MFI): This open-source, process-based life cycle assessment tool helps inform the manufacturing process from resource extraction to the factory gate ("cradle to gate"). By creating an inventory of the energy and materials used in the initial manufacturing stages through final production, MFI can model the energy use and greenhouse gas impacts of a range of manufacturing scenarios, including the effects of changes in production technology, increases in industrial energy efficiency, and supply chains.

Learn more about NREL's life cycle assessment work, and subscribe to receive updates on NREL energy analysis, including our quarterly newsletter.