Research Interests

Jessica Olstad has been with the National Renewable Energy Laboratory (NREL) since 2009. She has experience in materials characterization, analytical method development, and materials development and testing for concentrating solar applications, and she has worked on various bench-scale systems in the past, including micro-activity test systems and fluidized bed reactors, to study the effects of feedstocks and catalysts on gasification products. She is currently the lead engineer on the Davison Circulating Riser (DCR) unit, a subsystem of NREL's pilot-scale vapor-phase upgrading unit (VPU).

Vapor-Phase Upgrading

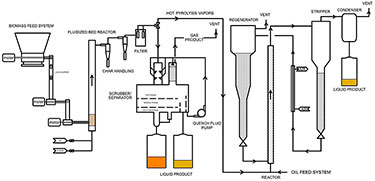

This research focuses on the integration of bio-based feedstocks with the existing petroleum refining infrastructure. The current petroleum infrastructure has difficulty incorporating bio-based liquid products (such as bio-oil) due to the high oxygen content, high viscosity, and immiscibility with petroleum feedstocks. A potential method of integrating these resources is by using bio-based vapors as feedstocks. NREL's VPU is composed of a pyrolyzer system and a DCR, a pilot-scale fluid catalyst cracking system. Each system can be run independently, but each is also configured to run as a single system. When the systems are connected, uncondensed vapors from the pryolyzer are sent to the DCR, where they are catalytically upgraded, and the products are condensed to produce a gasoline-like liquid fuel.

Olstad is very interested in studying the effects of feeding bio-vapors into the DCR system. Feeding vapors has the potential to change DCR operating parameters, which in turn change the overall product slate. Part of the challenge is figuring out how to work around the issues that arise from using the vapor feedstock, which she enjoys doing. Additionally, she is excited to study modified catalysts that are more suited for biomass-derived compounds to see how they affect the system and products.

Education

-

B.S., Chemical and Biochemical Engineering, Colorado School of Mines, 2009

Professional Experience

-

Staff Engineer, NREL, National Bioenergy Center, Thermochemical Sciences, 2009–present

-

Staff Engineer, NREL, Buildings and Thermal Systems, Concentrating Power Storage Systems and High-Temperature Fluids Development, 2009–2011

Featured Publications

-

"Regenerable Manganese-Based Sorbent for Cleanup of Simulated Biomass-Derived Syngas," Energy and Fuels (2011)

-

"Comparison of Sodium and Potassium Carbonates as Lithium Zirconate Modifiers for High-Temperature Carbon Dioxide Capture from Biomass-Derived Synthesis Gas," Journal of Undergraduate Research (2009)

View all NREL Publications for Jessica Olstad.

Share