Life Cycle Assessment and Photovoltaic (PV) Recycling: Designing a More Sustainable Energy System

April 19, 2016 by Brandon Kiger

What happens to solar panels and materials after their useful life? What role does recycling play in the lifecycle of photovoltaic (PV) systems? Is it possible to design PV in a “cradle to cradle”[1] approach so that materials are designed with the purpose of being reused, upcycled, or recycled to a safe and useable material instead of ending up in landfills? From 2010 to the 2nd-quarter of 2015, the U.S. has cumulatively installed 19,884 MWdc of PV in the residential, non-residential, and utility markets[2] Given the growth in solar installations over the last five years, exploring these questions is prudent for designing a more sustainable energy system.

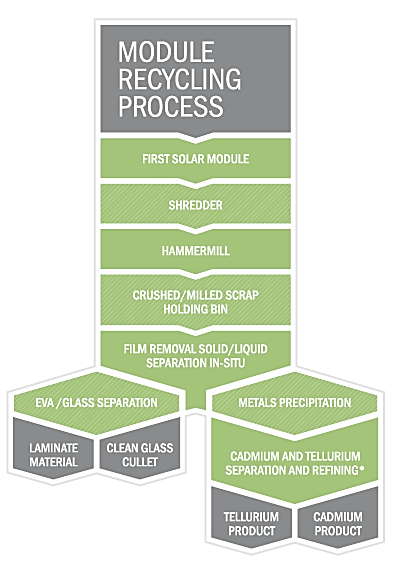

The National Renewable Energy Laboratory (NREL) estimates the useful life of PV systems to be approximately 25 to 40 years[3] depending on various factors such as environmental conditions. The stages in a PV system’s life cycle are illustrated below (Fig. 1). Note the many stages before and after the energy-producing portion of the life cycle.

Figure 1. Flow of life cycle stages for PV Systems

In conducting a life cycle assessment (LCA), researchers quantify the energy, greenhouse gas (GHG) emissions, and other impacts of each stage in a product’s existence. LCAs are also known as carbon footprints[4]and these footprints of technologies vary over time based on many factors such as material availability, the transportation of materials, and extracting materials. LCAs account for both the energy produced and environmental externalities (e.g., GHG emissions) throughout the life cycle of the technology. For example, the International Energy Agency (IEA) uses impact metrics such as Energy Payback Times, GHG, SO2, NOX and heavy metal emissions in conducting LCAs of various technologies.[5] More specifically, NREL has been contributing to the growing literature of PV LCAs. The NREL Life Cycle Assessment Harmonization Project found when comparing PV technology studies (crystalline silicon and thin film) to coal technology studies (e.g., sub- and supercritical, integrated gasification combined cycle, and fluidized bed) that approximately 40 grams of carbon dioxide equivalents per kilowatt hour (g CO2e/kWh) are released through the many stages of PV as compared to coal, which produces approximately 1,000 g CO2e/kWh.[6]

By quantifying PV life cycle stages, we can identify the role PV recycling may play in reducing GHG emissions as opposed to the energy-intensive process of extracting raw virgin materials for manufacturing. PV recycling systems vary depending on the type of PV panels (e.g., mono- or multi-crystalline Si, CdTe thin film, CIGS, etc.) as well as the construction of the panels and supporting materials. The economic values of the materials and the economics of recycling can fluctuate depending on market demand. For example, the value of glass may be as little as $0.07/kg while germanium may bring as much as $1,200/kg.[7] Moreover, these values vary in time. Bloomberg Business reports the spot price for silicon has been as high as $475/kg in 2008 while in 2015 it fell to less than $15/kg.[8]

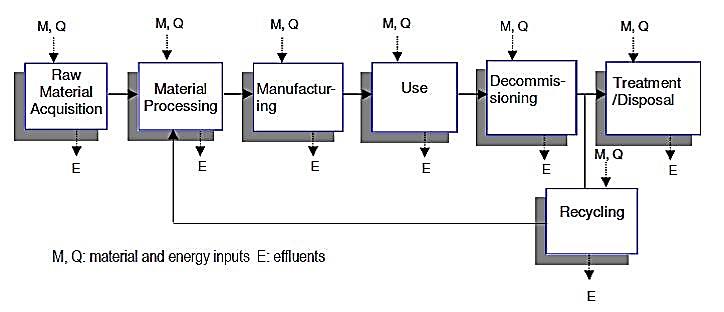

Some solar companies are taking the lead and benefiting from recycling PV panels and other PV system components such as racking (i.e., the components (typically made of aluminum) used for mounting roof or ground PV systems). For example, First Solar established the first global and comprehensive PV recycling program in 2005 (Fig. 2). According to First Solar, its “state-of-the-art recycling process achieves high recovery rates; up to 90% of the semiconductor material can be reused in new modules and 90% of the glass can be reused in new glass products.”[9]

While the PV recycling market continues to develop, customers can track the sustainability of the solar industry by visiting the Silicon Valley Toxics Coalition (SVTC) annual scorecard and website. SVTC identifies solar companies that consider the ‘full’ lifecycle of their products and have a high percentage of PV recycling or recovery.

Fig. 2. First Solar’s Module Recycling Process.

*Cadmium and tellurium separation and refining are conducted by a third party.

[1] Braungart, M. & McDonough, W. (2002). Cradle to cradle: Remaking the way we make things. New York: North Point Press.

[2] Greentech Media Inc. (GTM) and Solar Energy Industry Association (SEIA). 2015. U.S. Solar Market Insight Report. Quarter Two.

[3] http://www.nrel.gov/analysis/tech-footprint.html

[4]Retrieved from http://www.parliament.uk/documents/post/postpn_383-carbon-footprint-electricity-generation.pdf.

[5]International Energy Agency (2015). Life cycle inventories and life cycle assessments of photovoltaic systems. Retrieved from http://www.iea-pvps.org/index.php?id=315 .

[6]Retrieved from https://www.nrel.gov/docs/fy13osti/56487.pdf .

[7]Center for Life Cycle Analysis, Columbia University and Photovoltaics Environmental Research Center, Brookhaven National Laboratory (2014). PV life cycle management and recycling: Overview and prospects. Presentation retrieved from http://iea-pvps.org/fileadmin/dam/public/workshop/02_Vasilis_FTHENAKIS.pdf .

[8]Retrieved from http://www.bloomberg.com/news/articles/2015-11-13/solar-power-is-booming-and-its-biggest-component-is-dirt-cheap.

[9] Retrieved from http://www.firstsolar.com/en/Technologies-and-Capabilities/Recycling-Services.aspx.

Share