New NREL Method Reduces Uncertainty in Photovoltaic Module Calibrations

Jan. 29, 2018 by Dean Levi

To reliably calibrate the power of their modules, photovoltaic module manufacturers rely on calibration traceability to certified test laboratories. This reliable calibration, in turn, determines the selling price of the module. The financial impact of each additional 1% uncertainty in module power is up to $3.5 million USD for each 1 gigawatt of production at a module sales price of $0.35/watt.

In NREL’s Cell and Module Performance group, we recently developed a new procedure for measuring the power of commercial crystalline-silicon photovoltaic modules that reduces the uncertainty in module maximum power (Pmax) to ±1.1% (k=2 coverage factor). This value is the lowest reported Pmax uncertainty of any accredited test laboratory in the world.

Our NREL team coined the term "module self-reference," or MSR, for this new procedure. The two biggest factors contributing to uncertainty in module calibration are temperature uncertainty and spatial nonuniformity of the light source. The new procedure minimizes both of these factors by using the module itself as a thermometer and a reference device to set the light level of the simulator in the final measurement of module power.

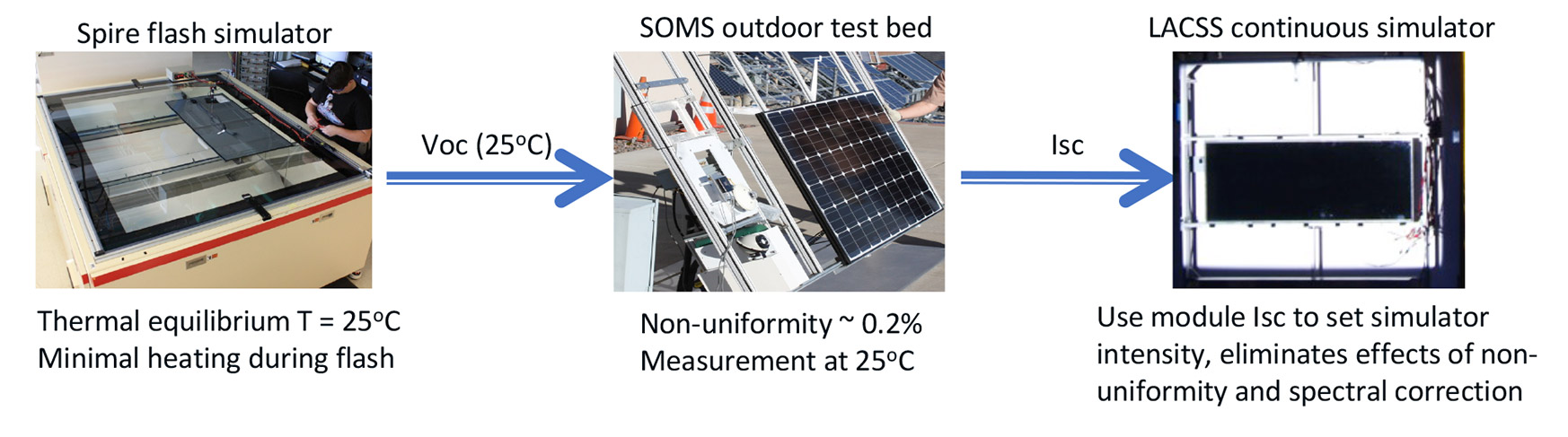

We summarize the procedure as follows:

- First, we calibrate module open-circuit voltage (Voc) vs. irradiance using a pulsed simulator with the module in thermal equilibrium at 25°C. This calibration provides a sensitive internal "thermometer" for subsequent measurements.

- Second, we cool the module to ~15°C, then mount it on an outdoor test bed and monitor Voc as the module heats. The current-voltage (IV) curve is measured when the module reaches 25°C, which provides a measure of short-circuit current (Isc) with minimal uncertainty because of the highly uniform irradiance of natural sunlight.

- Third, we again cool the module to ~15°C and mount it in a continuous simulator. Voc is monitored until the temperature reaches 25°C, and we use the module Isc from the outdoor measurement to set the light level on the simulator—thus eliminating errors due to spatial nonuniformity of the light source and spectral mismatch with the reference cell.

- Finally, we again cool the module to ~15°C, remount it on the continuous simulator, and monitor Voc until the temperature reaches 25°C. We then measure the IV curve, which provides an accurate measure of Pmax at 25°C and 1,000 W/m2.

Contact Dean Levi for more information.

Share