Outdoor Test Facility and Related Facilities

Outdoor Test Facility (OTF) researchers study advanced and emerging photovoltaic (PV) technologies under simulated, accelerated indoor and outdoor, and prevailing outdoor conditions.

The Outdoor Test Facility is used to evaluate prototype, pre-commercial, and commercial PV modules.

Researchers at the OTF work with industry to develop uniform and consensus standards and codes for testing PV devices. Researchers also calibrate primary reference cells for in-house use and use by other national laboratories, calibration and testing labs, and PV manufacturers.

Indoor Testing

We use an assortment of indoor equipment, described below, to test modules and systems under simulated and accelerated conditions as well as to perform module packaging R&D. Our equipment is housed in several laboratories in buildings across NLR, including the OTF, the Field Test Laboratory Building (FTLB), and the Solar Energy Research Facility (SERF).

High-Bay Accelerated Testing Laboratory (OTF)

The Atlas 260 is one of several accelerated-testing chambers in the high-bay laboratory at OTF.

The OTF High-Bay Laboratory houses the OTF accelerated testing equipment, which can be used to weather PV modules in environments with controlled temperature, ultraviolet (UV) exposure, and relative humidity.

The OTF High-Bay Laboratory houses the OTF accelerated testing equipment, which can be used to weather PV modules in environments with controlled temperature, ultraviolet (UV) exposure, and relative humidity.

- Atlas XR260 – Accelerated Xenon weathering system (2.5-suns full spectrum; temperature-humidity cycling; light soaking; 6' x 4' module capacity)

- UV exposure unit – UVA fluorescent light-soaking (4' x 8' test plane)

- Environmental chambers (5) – Temperature-humidity cycling; electrical module biasing during cycling; range of sizes and temperature ranges.

Failure Analysis (OTF)

This laboratory contains additional testing and evaluation equipment.

- Module leakage current testing – "Hi-pot" testing; modules tested either dry or immersed in wetting solution while high voltage is applied.

- Infrared (IR) Camera – Takes IR photographs of systems or modules to pinpoint which areas are malfunctioning.

Optical Mechanical Characterization Laboratory (FTLB/158-01)

The Optical Mechanical Characterization Laboratory is at the center of our research on module packaging R&D.

Optical Characterization Equipment

The equipment described below is useful in measuring the optical properties of test samples—their ability to reflect or transmit light.

- Lambda 9 Spectrophotometer – Versatile, high-performance double-beam, double-monochrometer UV-visible-NIR spectrophotometer with integrating-sphere attachments; can measure the hemispherical reflectance and transmittance of samples compared with secondary reflectance standard; the absolute reflectance to be measured as per ASTM E903-82 for wavelengths, 250 to 2,500 nm for reflectance and 200 to 2,600 nm for transmittance

- D&S Instruments Portable Specular Reflectometer 15R – Field and laboratory measurements of specular reflectance (non-scattered) on curved or flat samples; 660 nm LED and collimating optics produce 10-mm diameter source beam, which is focused through three-thumbwheel selectable aperture; standard acceptance angles are 7, 15, and 25 milliradians

- Microscopes accessorized with digital imagery

- Meteorological monitoring/recording station – Currently used to monitor/record local conditions at the Golden, CO outdoor test site

Mechanical Characterization Equipment

We use the equipment described below to characterize the mechanical properties of test samples—strength, adhesion, and ability to keep out moisture and oxygen.

Researchers use a variety of equipment to test cells and modules.

- Instron 5500R – Electromechanical test instrument; computer system allows dynamic

testing; tabletop load-frame for maximum load of 0.5 kN; performs the following mechanical

tests for metals, wood, polymers, and other materials at -150°C to 600°C:

- Compression – Yield strength, yield point, elastic limit, and compressive strength

- Tensile – Ultimate tensile strength, modulus of elasticity, or Young's modulus

- Modulus of elasticity in shear, yield shear strength, ultimate shear strength, modulus of rupture in shear, and ductility

- Creep properties and stress relaxation, fatigue, flexure, impact – Ductile or brittle

- Pull testing – 90° and 180° pull test, elongation at break, peel strength, butt joint, and lap-shear adhesion

- Hot water baths – Used to condition absorber materials in hot water before being pulled on Instron 5500R

- Sebastian Quad Pin-Pull – Adhesion or material-strength measurements (Sebastian quad, pin-pull, etc.)

- Mocon Permatran W 3/31 – Measures the amount of moisture that diffuses across polymers; blows dry air along one side of polymer membrane and humidified air along the other side, measuring the transient water-vapor transmission rate; diffusivity, solubility, permeability of a tested polymer can be determined by fitting measurements to theoretical modules; measurements are made 20°C to 85°C, 100% relative humidity

- Thermogravimetric analyzer – Directly measures water up-take in a sample to analyze water diffusivity in samples (in progress)

- Mocon OxTran-100 – Measures the oxygen transmission rate through synthetic film, coated papers, and other flexible or semi-rigid packaging materials; oxygen flows on one side of the barrier and an oxygen-free carrier gas flows on the other side, carrier gas conveys the oxygen that diffuses through the barrier to oxygen-specific coulometric detector; measurements are made ambient to 70°C, 0% to 100% relative humidity

- TABER® Abraser (Abrader) Test – Measures abrasion resistance for accelerated wear testing

- Rockwell or Vickers hardness testing—Tests sample hardness by applying force on a sample using a diamond stylus; measures the amount of indentation to calculate hardness

Accelerated Exposure Testing Laboratory (FTLB/158-03)

We use these temperature- and humidity-controlled chambers to test for weathering durability, corrosion on mirrors, delamination of polymers under controlled conditions, and other research. The conditions listed along with the equipment represent current tests.

- Blue M Temperature/Humidity Oven (85°C, 85% relative humidity)

- Bench-top Blue M temperature-only ovens (2)

- Lab-line vacuum oven (85°C with nitrogen purge)

- Q-Panel QUV – Thermal moisture cycles (UV at 50°C; dark cycle at 30°C with condensation)

- Atlas CI-65 – Accelerated weathering machine (1 sun, 60°C and 60% relative humidity)

- Oriel 1000W Solar Simulator – Accelerated weathering machine (70°C, 70% relative humidity)

- Oriel 1400W Solar Simulator – Accelerated weathering machine 8-chamber system; half exposed to UV light, the other half dark; can do four combinations of temperature (high or low) and relative humidity (high or low)

- Atlas CI 5000 – Accelerated weathering machine (2 suns or equivalent of six times outdoors; 60°C, 60% relative humidity)

- Atlas Suntest Chambers (2) – Accelerated weathering chambers (1.3 suns, ambient relative humidity, 75°C, 40°C)

Researchers use equipment in SERF/E216 to prepare, evaluate, and test samples.

PV Module Encapsulation Research Laboratory (SERF/E216)

Sample Preparation Equipment

The equipment described below aids in sample preparation.

- U.S. Stoneware Roll Mill – Blends or roll-mixes polymer pellets with formulation additives using controllable speed

- Carver Model 3393 Lab Press/Watlow Series 981 Temperature Controller – Thermal pressing or treatment of film samples

- C.W. Brabender Bench-top Film Extruder – Used to extrude polymeric encapsulant films from the formulated polymer pellets that are developed and tested as new encapsulant films

- C.W. Brabender Polymer Extrusion System – Heats and extrudes polymer encapsulant films from formulated polymer pellets; achieves controlled thicknesses; used to prepare new films for testing

- Custom-Built Double-Bag Vacuum Laminator (Astro Power LM-404) – Laminates solar cell devices (glass/encapsulants/backing materials) and cures encapsulant films for lab-scale specimens up to 16" × 16"

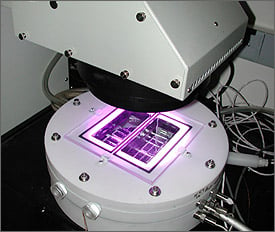

Accelerated Exposure Systems

We use these temperature- and humidity-controlled chambers to test samples under simulated and accelerated conditions.

- UV Solar Simulators (2) – Accelerated exposure of samples in UV range to 450 nm with an integrated 300 to 400 nm intensity of 5 UV suns

- Full-spectrum Solar Simulator – Xenon arc; exposure in UV-visible to IR range with integrated 300 to 400 nm intensity of 5 to 7 UV suns; light-exposing area is 6" × 6"

- Light source – Condensable light beam for variable intensity

- DSET 1.8-kW Suntest Table-top Exposure Chambers (2) – Exposure of samples under an intensity of 1 to 1.2 UV suns

- Atlas Ci4000 – Xenon arc accelerated environmental weathering chamber (6,500 cm2 exposure area, 2-sun irradiance, 40° to 115°C, 10% to 75% relative humidity, simulated rain/condensation sprays

Additional Equipment

The equipment described below rounds out the capabilities of the laboratory.

- Omnimark Mark 4 Moisture Analyzer – Quantifies water content in samples using thermal heating methods

- Rame-Hart Goniometer – Measures contact angle

- Lab-Line Duo-Vac and Squaroid Duo-Vac ovens – Controlled ovens for dark sample exposure at elevated temperatures; useful for contrasting/comparing dark/heat vs. light/heat stress effects; dries sample preparations with or without vacuum

Outdoor Testing

The Outdoor Test Facility forms the backbone of our field-testing capabilities.

Nearly 40 test beds surround the OTF building. These test beds allow researchers to characterize the electrical output performance of modules under outdoor conditions, test the long-term performance and stability of PV modules and systems under standard and accelerated outdoor conditions, and measure the performance of hybrid systems. Systems used for PV measurement include Standard Outdoor Module Characterization, Long-Term Module Outdoor Performance and Stability, and Grid-Tied PV Systems Testing.

Standard Outdoor Module Characterization

Researchers use two I-V measurement systems to measure the electrical output performance of PV modules under outdoor conditions that are as close to possible to standard test conditions. One system is the Standard Outdoor Measurement System, a fixed system on which modules are placed for testing and can track the sun. We attempt to make these measurements under a clear sky, with the irradiance between 950 and 1050 W/m2, and as close to 25°C as possible. For each measurement, we use a pyranometer and a silicon reference cell in a module package to determine the total irradiance, and a spectroradiometer to determine spectral content of the sunlight between 350 and 1,100 nm. Once the operator has set the parameters, the system measures the I-V characteristics and the temperature, and calculates other performance characteristics.

The other system is a portable one used in the field to measure output characteristics of modules or strings.

Modules undergoing Performance and Energy Rating Testbed testing.

Long-Term Module Outdoor Performance and Stability

Long-term module performance testing is conducted on the Performance and Energy Rating Testbed, located on the roof of the OTF, and in the array field. The Performance and Energy Rating Testbed is used to continuously monitor modules of various technologies for performance under various weather conditions. In the adjacent array field, test beds are used to conduct outdoor exposure and stability tests on more than 50 PV modules.

Grid-Tied PV Systems Testing

Grid-tied, 1- to 3-kW PV systems are installed at the OTF. These systems employ various PV module technologies, including copper indium diselenide, cadmium telluride, and crystalline silicon. These systems are monitored for long-term performance and reliability.

Share

Last Updated Dec. 6, 2025