NREL Research Pushes Perovskites Closer to Market

Newest solar technology proves nearly 23% efficient

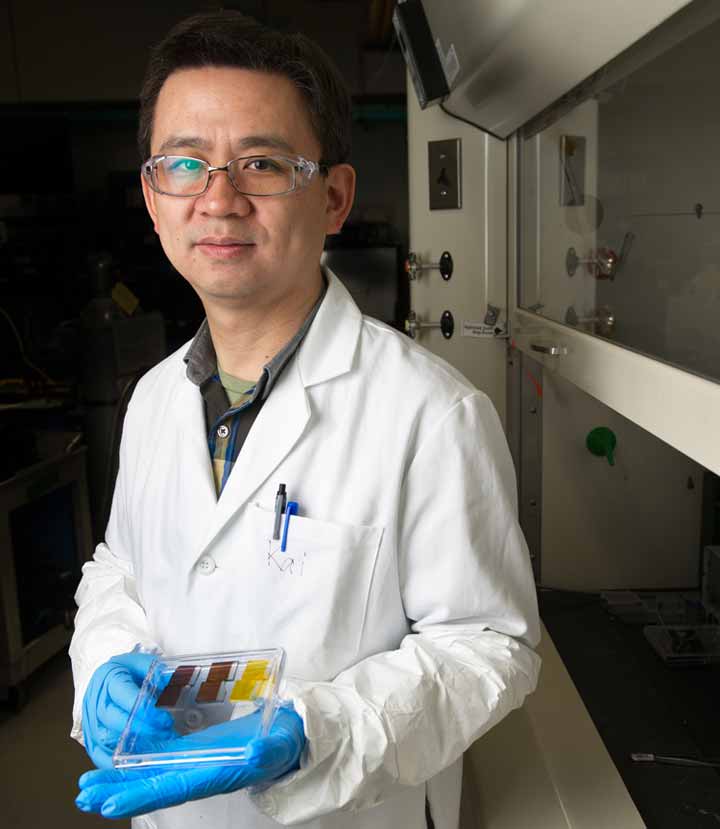

An NREL scientist holds a container of a perovskite ink formulation that can be painted onto a surface to create a solar cell. Photo by Dennis Schroeder/NREL

Kai Zhu, a researcher at the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL), spent a decade trying to wrest the highest possible efficiencies from dye-sensitized solar cells. “Work on the traditional dye cell was not going well,” he recalled. “It was relatively flat in terms of performance. People in the field were frustrated.”

Initially able to convert 7% of sunlight into electricity, dye cells ticked upward to about 11% in 2004 and held fast. Despite the best efforts of scientists around the world, the dye cell couldn’t catch up—or even get close—to the above-20% efficiencies dominated by silicon solar panels.

Kai Zhu has been conducting perovskite research at NREL since 2012. Photo by Dennis Schroeder/NREL

Then, because research requires thinking about problems differently, some scientists tried supplementing the dye cells with organic-inorganic hybrid crystalline materials: perovskites. The combination captured more of the sun’s energies but increased the efficiency only by a few percentage points. Other scientists discovered perovskites alone were highly effective at absorbing sunlight. Initial published research showed a perovskite solar cell with an efficiency of approximately 3% in 2009. That number more than doubled within two years and more than tripled by 2012, when Zhu and other NREL researchers shifted their efforts.

“Perovskites were unstable and there were all kinds of problems—but you could clearly see in all the measurements that these were high-quality semiconductors,” said Jao van de Lagemaat, director of NREL’s Chemistry and Nanoscience Center. “We saw where efficiency records were broken day after day after day. We realized this is not something we should be ignoring.”

Scientists are continually testing the use of new materials, including for solar cells, “but no one really cares unless you come up with an exciting benchmark,” said NREL Senior Scientist Joseph Luther, “and that’s what happened with perovskites.” It wasn’t until the publication of the third or fourth paper on perovskite research—the 2012 paper that revealed more than 10% efficiency—that the scientific community began paying attention. “It had to gain momentum,” Luther added.

Manufacturing Price Pales Next to Cost of Silicon

Zhu, Luther, and others at the laboratory convinced NREL in 2014 to construct an environmental chamber where they could research perovskites. They already knew moisture made perovskites unstable, so being able to control humidity was vitally important. They also knew perovskites could be made by a chemical solution and manufactured by a roll-to-roll process similar to how newspapers are printed.

“The cost is very low,” said Zhu, who joined NREL in 2004 as a postdoctoral researcher and became a staff scientist three years later. “That’s a selling point for this.”

Perovskites have a couple of major benefits over silicon solar panels. The silicon technology requires a high-temperature manufacturing process, whereas the perovskite process is simpler: chemicals are applied to a substrate, either by deposition or roll-to-roll printing. When dry, the residue leaves crystals that serve as excellent semiconductors. This means perovskite panels are more flexible than rigid silicon panels, making them ideal for applications such as solar panels that are built into backpacks or that power drones.

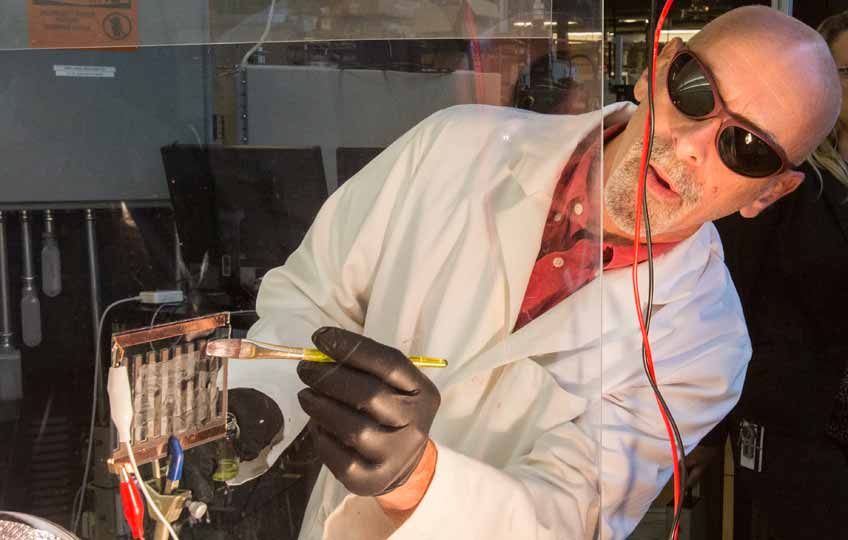

“I don’t see anything that stands in the way of commercialization of perovskites,” said David Moore, a staff scientist at NREL who has pioneered a way to apply perovskites onto a surface as a paint. “There are a couple of challenges left. We need to make sure they’re going to last 30 years. But the strides we’re making in those areas are just as rapid as the progress we made with efficiency in the first five years. Just based on the progression of both of those things, there’s every reason to believe that we’ll continue on that path to solve those problems and you’ll start to see perovskite solar cells that you can buy.”

The record efficiency for a perovskite solar cell, certified by NREL last summer, now stands at 22.7%. The laboratory regularly charts the efficiencies of perovskites and other solar technologies. Moore said photovoltaic (PV) materials typically follow the same path: a steep climb up the chart, then a decade or more during which efficiency plateaus and only small improvements are made as researchers discover and solve fundamental problems. When those challenges are overcome, the technology tends to take another steep, upward turn on the efficiency chart.

“Perovskite has only had one slope and it’s been very steep,” Moore said. “Its first entry on the NREL chart was higher than most of the other technologies had after 10 years. It started high and its slope has also been high. That’s why people are so excited.”

Pioneering Cutting-Edge Research

In a solar cell, perovskites absorb energy from the sun, which knocks electrons free. As the electrons move back toward their original locations, they generate electricity while traveling through layers above and below the perovskite. The laws of physics put the theoretical maximum efficiency for a single-junction solar cell at 33%—about a third of energy from the sun can be converted into electricity. Another third is lost to heat and the rest to other processes. Carrying a charge, the electrons reach a higher temperature than their surroundings but these “hot carriers” revert to normal in a matter of femtoseconds. NREL Emeritus Researcher Arthur Nozik theorized decades ago that the energy lost to heat instead could be recaptured to double the maximum efficiency of a solar cell.

“We found out these hot carriers can live much longer than anything we’ve seen before and that perovskites are somehow special in this sense,” van de Lagemaat said. “This could lead—if we figure out a way to exploit this phenomenon—to very high-efficiency solar cells.”

He and other NREL researchers determined that hot carriers encounter a bottleneck where heat-carrying particles called phonons reheat the charge carriers, thereby drastically slowing the cooling process and allowing the carriers to retain much more of their initial energy for significantly longer periods of time.

Over the past year, NREL scientists delving into perovskites also:

- Devised a method to make perovskite solar cells more efficient and reliable. Coating a low-quality perovskite film with a specific chemical solution improved its efficiency and stability.

- Discovered a way to improve the quality of perovskites. A critical stage in the creation of perovskites requires the addition of an antisolvent that extracts precursor chemicals. The window for this step opens and closes within seconds, but NREL researchers were able to keep it open for as long as eight minutes.

- Determined a polycrystalline perovskite solar cell functions better than its single-crystal counterpart. Electrons moving through the cell can encounter defects and slip into a non-productive state known as recombination, but the recombination must occur slowly for the cell to be most efficient. Recombination in the single-crystal sample was almost 10 times faster than in its polycrystalline counterpart.

- Examined potentially scalable methods to deposit perovskite ink onto substrates. Efficiency in a perovskite solar cell declines as the cell and module area increases. A combination of factors is attributed to the decline, including the non-uniform coating of chemicals in the cell, so it’s important to find the best technique.

Luther, along with colleague Jeffrey Christians, also found that changing the layers that sandwich the perovskite within a solar cell was enough to drastically improve performance. Instead of an immediate decline in performance, their experiments revealed that using the different materials allowed the cell to continuously generate power for more than 1,000 hours. The first cell they tested recorded an 18% efficiency in its brief life, but efficiency was sacrificed for stability and the efficiency of the cell with different layers maxed out at 15%. “Now that we know we can make it more stable when we change this layer out for another,” Luther said, “let’s get the performance back up as high as we can possibly get it, knowing that in the future we’re going to want this combination of materials.”

Luther presented the results of his research at a conference in Malta in October—the 10th Annual International Summit on Stability of Organic and Perovskite Solar Cells—which drew more than 100 participants from 35 countries. One debate revolved around the best way to measure how long a perovskite solar cell might last, although the gathering ended without a consensus. “Which cell is better? The one that was measured at no humidity for 1,000 hours, or the one that was measured at ambient conditions for 500 hours?” asked Luther, who sits on the conference’s international scientific committee.

But researchers can’t wait for 1,000 hours or longer to test the stability of a perovskite solar cell. They need the answers sooner. “We would like to make a measurement that in 10 minutes would tell if our solar cell would last 30 years,” Luther said. “But that’s a very challenging thing to develop.”

“Although there are still many obstacles, many challenges, if you wait until all challenges are cleared up and then start to work on it, by that time that will be too late,” Zhu said. “That’s a risk factor you have to consider when you invest in new technology. The next three to five years will be very exciting.”

Learn more about NREL’s PV research.

Last Updated Jan. 22, 2026