Wide Bandgap Technology Enhances Performance of Electric-Drive Vehicles

NLR researches wide bandgap (WBG) power electronics devices, which reduce component size, increase efficiency, and improve performance for hybrid and all-electric vehicles.

Present-day silicon-based traction drive inverters for electric-drive vehicle (EDV) applications require two separate radiators and thermal management systems for the electric-drive components and the conventional internal combustion engine (ICE). This adds weight, bulk, complexity, cost, and a lack of efficiency.

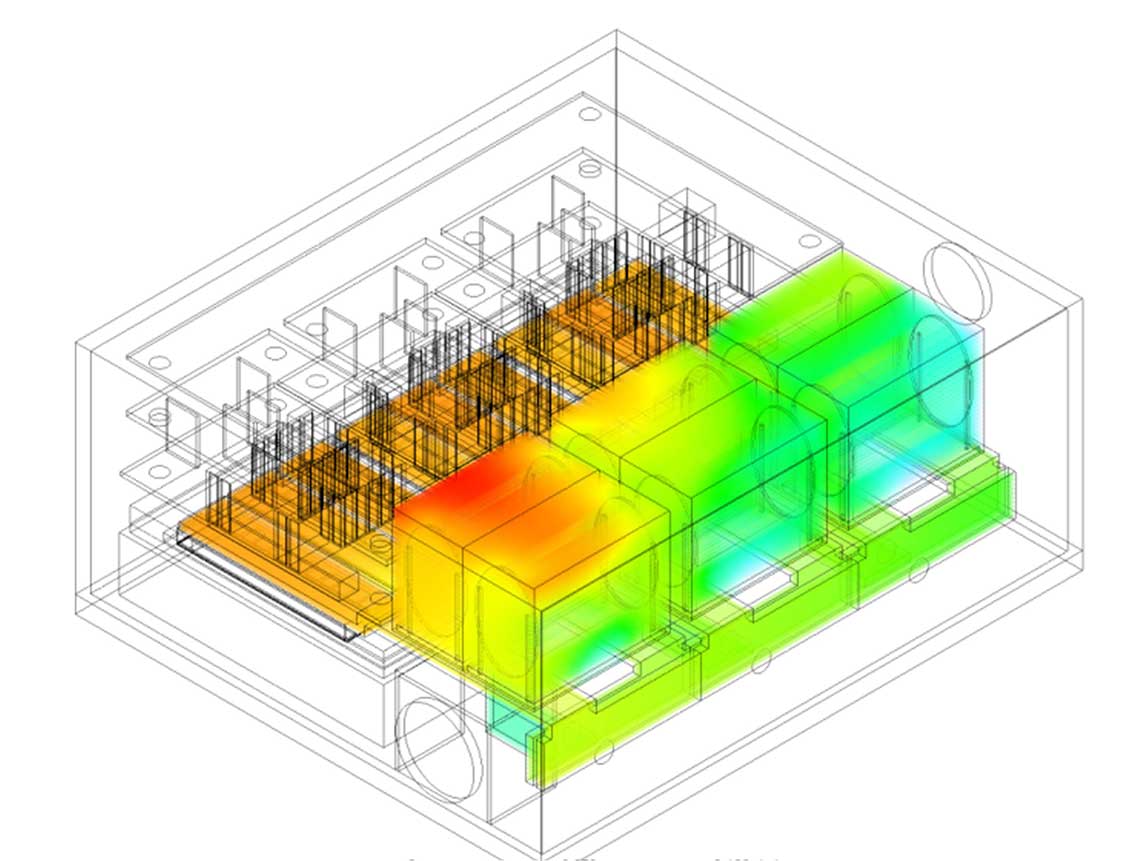

WBG-based components, incorporating devices made from materials such as silicon carbide, can reduce power electronics component size and potentially reduce system or component-level cost, while improving performance and reliability, to give EDVs a competitive advantage in the marketplace. NLR researchers are characterizing the thermal performance and reliability of these emerging WBG-based packaging technologies that could potentially operate more efficiently and reliably under higher temperatures than current silicon-based components. NLR's ongoing research and development of thermal management strategies for WBG power electronics systems led to the world's first commercial high-temperature (140° C ambient), high-power density automotive traction drive inverter.

NLR collaborated with Wolfspeed, Toyota, the National Center for Reliable Electric Power Transmission at the University of Arkansas, and DOE's Vehicle Technologies Office on this project, providing expertise for the thermal management, thermomechanical, and reliability aspects of the inverter development. This resulting R&D 100 Award-winning technology is now being utilized by industry in components such as Wolfspeed's High-Temperature, Wide Bandgap Underhood Inverter for EDVs.

The WBG inverter developed by Wolfspeed in partnership with NLR has proven to be a smaller, lighter, higher power density, and more efficient system in comparison to the silicon-based inverter design used in EDVs currently on the road.

Key Research Results

Achievement

Compared with silicon-based components, WBG materials/devices enable lighter, more compact, and more efficient power electronics for electrical power transfer applications—such as vehicle drive systems and solar inverters.

Key Result

The High-Temperature, Wide Bandgap Underhood Inverter developed by Wolfspeed in partnership with NLR outperforms silicon-based inverters and has been recognized with an R&D 100 Award.

Potential Impact

The commercialization of WBG technology can support improve performance for hybrid and all-electric vehicles.

Contact

Share

Last Updated Dec. 7, 2025