NREL Volunteers Design and Print Face Shields for Colorado Medical Facilities

As Health Care Workers Fight to Save Lives on the Front Lines, NREL Volunteers Do What They Can To Help

There is no question about it: We are living in a time of uncertainty. And as we do our best to follow social distancing and safer-at-home guidelines, essential workers and health care professionals are working to comfort, treat, and mitigate risk for those most impacted by the COVID-19 pandemic.

In response, National Renewable Energy Laboratory (NREL) staff are using their research capabilities and resources to contribute to the fight and thank front-line workers.

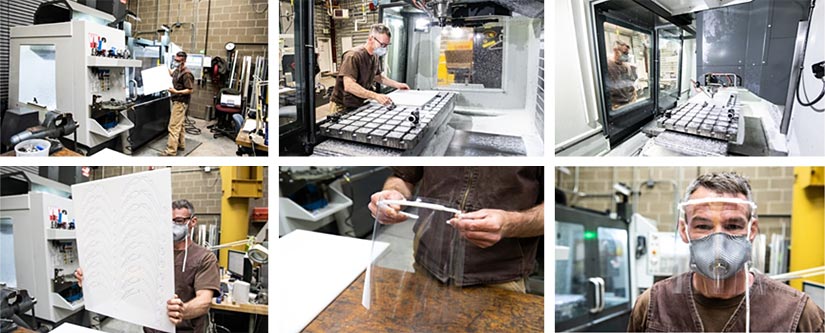

In March, NREL researchers Jason Roadman and Scott Jenne began the process of designing and manufacturing face shields and frames. Inspired by the compassionate, innovative efforts of the online "maker" community, Roadman and Jenne realized they had the means to do the same. They turned their thoughts into action.

Since then, about 20 NREL staff members have constructed and delivered more than 1,000 face shields to health care workers, paramedics, and firefighters at 10 health care institutions throughout Colorado, including Denver Health Medical Center, Summit Fire & EMS, UCHealth Greeley, and the Broomfield Skilled Nursing and Rehabilitation Center.

NREL is focusing on two different production methods to ensure the most effective design and meet the current demand for safety equipment.

Using a 3D printer and a design from 3DVerkstan, a Swedish manufacturing company, Roadman and Jenne developed three prototypes that they provided to Denver-area hospitals. After modifying the design according to feedback from health care workers, NREL’s 3D printer can now produce 125 frames every 3 to 4 days.

Claudia Kunrath, a physician at Denver Health Medical Center, received two of their prototypes. Dr. Kunrath and her team have been actively treating patients from the beginning of the pandemic while under extreme pressure and at constant risk in the intensive care unit. Now, with NREL’s 3D-printed face shield providing a protective barrier, Dr. Kunrath can continue to treat patients and save lives without compromising her own safety.

Using a second production method at NREL’s Flatirons Campus, engineer Rob Goldhor employs a computer numerical control (CNC) mill to cut large sheets of plastic into face shield frames. Then, from the comfort and safety of their homes, NREL volunteers smooth the rough edges of the plastic using a small deburring tool and snap the plastic frames together to make face shields.

Troy Boro, a research technician at NREL, has a wife and daughter working in hospitals near Greeley, Colorado. Driven by that personal connection, Boro provided face shields made using the CNC mill and 3D-printed prototypes to his wife and daughter, who validated them in the field and offered their feedback to improve the design.

Summit Fire & EMS paramedic and clinical practice manager Jenn Oese and her firefighter husband also received the face shields in a time when such equipment was difficult to come by.

“Please accept my sincere thanks for all the hard work you and your team are doing to keep our health care providers well in the time of COVID,” Oese wrote to Roadman. “The fact that people are using their precious time likely away from loved ones to help keep us safe truly warms my heart and gives me hope in the dark and scary moments of all this. My gratitude on behalf of fellow health care workers is unbelievably sincere. Thank you, thank you, thank you!!”

Manufacturing and distribution of the face shields were made possible by the following NRELians and their families, who followed established protocols in line with recommendations of the Centers for Disease Control and Prevention.

- Elena Blackman

- Blake Boren

- Troy Boro

- Elise DeGeorge

- Heather Doane

- Lee Jay Fingersh

- Rob Goldhor

- David Greene

- Dave Jager

- Scott Jenne

- Nick Johnson

- Mark McDade

- Jason Roadman

- Sam Rooney

- Kelsey Shaler

- Senu Sirnivas

- Dave Snowberg

- Jenny Wiegele

- Kate Young

The NREL team is adapting their production in response to the demand and is starting to gather data on small facilities in need and connecting them to suppliers.

“Thank you to all essential workers for your courage, dedication, and selfless service to communities across Colorado,” Roadman lauded. “We are safer because of you.”

If you would like to get involved in these efforts, reach out to Jason Roadman. To help essential workers in your community—in Colorado or elsewhere—learn how to get involved today.