Photovoltaic Cells Commercialization

NREL, in collaboration with industry, developed the materials needed to boost the feasibility—and marketability—of transparent, flexible, organic photovoltaic cells.

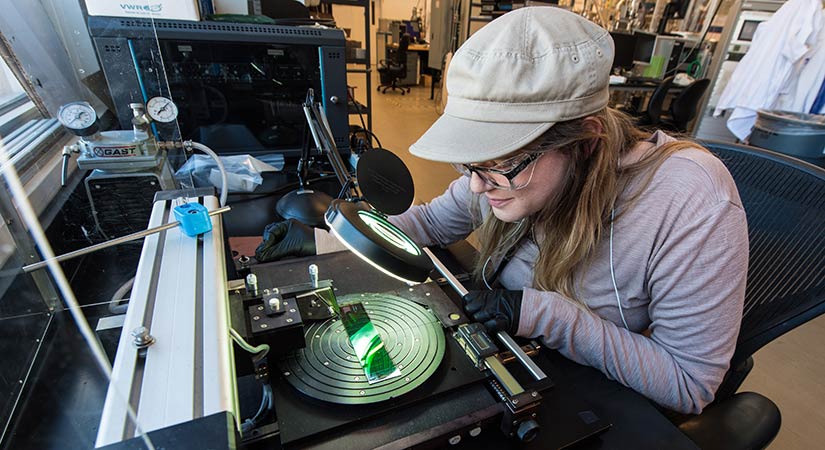

Using advanced manufacturing methods, NREL plays a role in pioneering flexible, thin-film photovoltaic cells for commercialization.

What would this look like? Well, take a look outside, and imagine viewing your surroundings through an electricity-generating window.

Through a cooperative research and development agreement, NREL helped SolarWindow Technologies Inc. develop new and improved coatings and technologies to:

- Lower costs

- Enhance scale, efficiency, and reliability

- Optimize processes to easily integrate technology into industry.

NREL executed a roll-to-roll manufacturing technique using laser technology as part of the manufacturing process of electricity-generating windows on flexible materials and other surfaces.

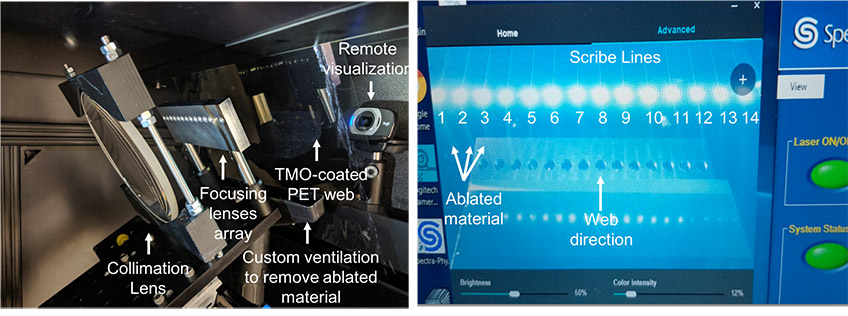

Laser scribing is a technique used to etch fine lines of specified patterns on the surface of each thin-film layer to enable monolithic interconnection between individual solar cells. A multiplexed laser scribing system developed by SolarWindow and NREL can scribe multiple parallel lines into a coated web.

These efforts were enabled by the U.S. Department of Energy's former Advanced Manufacturing Office.

Impact

Organic photovoltaic cells can be flexible and transparent and enable electricity generation on glass. As transparent solar panels are integrated into building exteriors and designs, city skylines become clean power generators without compromising building design or function.

Capabilities

NREL offers comprehensive organic photovoltaic research capabilities, which can help determine the feasibility of multiplexed laser scribing for scalable, high-throughput thin-film photovoltaic module production and commercialization.

Analysis Capabilities

Analytical tools have been developed for characterizing scribe line quality, as well as cell and module performance.

Device Fabrication

The multiplex laser scribing tool is designed to fabricate full modules, which NREL uses to fabricate flexible thin-film photovoltaic modules. Results are compared to modules made with a single-laser in a sheet-to-sheet processing tool.

Atmospheric Processing

NREL's Atmospheric Processing Platform has integrated tools for the depositing, processing, and characterizing of photovoltaic materials and manufacturing; specifically, NREL used the single beam scribing tool to optimize scribing parameters.

Roll-to-Roll Manufacturing

NREL's roll-to-roll processing capabilities are used to coat and laser process plastic substrates. Currently the coating and processing systems are separate, but in a commercial manufacturing environment they can be integrated to streamline production and throughput.

Partners

For this project, NREL worked with SolarWindow Technologies Inc. and received technical support of Argonne National Laboratory to help validate and optimize the scribe quality, uniformity, and stability.

Contact

Share