Oxide Electronic Devices for Extreme Operating Environments

NREL leads a three-party collaboration in developing oxide electronic devices for extreme operating environments.

NREL's state-of-the-art materials science capabilities are leveraged to advance high-temperature electronic devices. Photo by Dennis Schroeder, NREL

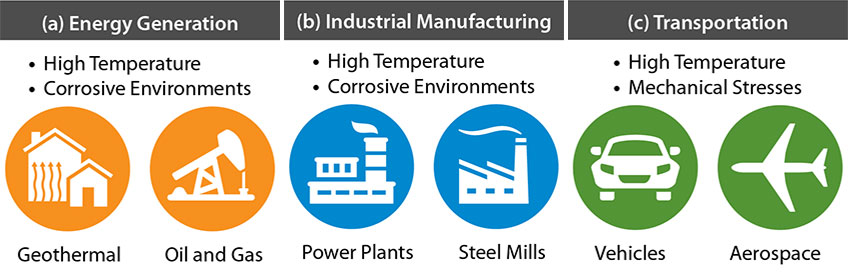

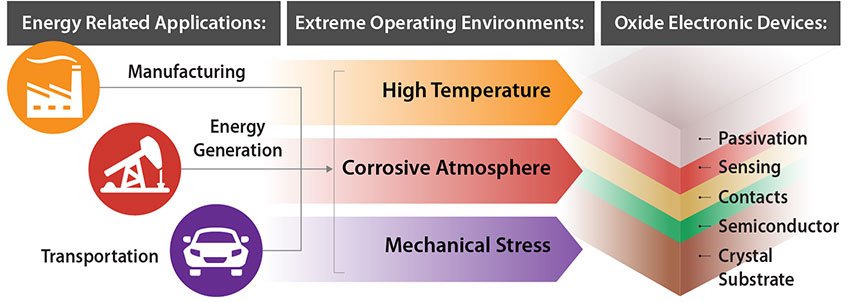

Electronic devices that can operate in extreme environments with coupled mechanical, thermal, and chemical stresses could significantly advance energy-conversion technologies, industrial manufacturing processes, and part of the transportation sector.

NREL is working to demonstrate oxide electronic devices suitable for extreme operating environments, including high temperatures, corrosive atmospheres, and mechanical stresses.

To achieve this goal, the project team is working to:

- Improve manufacturing of gallium oxide single-crystal wafers

- Use the improved wafers to fabricate oxide semiconductors devices and sensors

- Evaluate the device performance and reliability under extreme conditions.

Compared to established silicon and emerging wide-bandgap semiconductors such as silicon carbide and gallium nitride, high-temperature gallium oxide electronic devices have the potential for:

- Lower costs

- Better performance

- Higher energy efficiency

- Increased reliability.

The U.S. Department of Energy's Advanced Materials and Manufacturing Technologies Office provides funding and facilities support to these efforts.

Impact

NREL's research addresses technology gaps to make reliable and inexpensive high-temperature electronic devices for energy related applications

This research is increasing the operating temperature and service lifetime of electronic devices while maintaining performance and reducing the manufacturing costs. Once validated, these electronic devices could significantly improve many energy technologies and manufacturing processes like geothermal energy extraction, aluminum alloy plants, and next-generation vehicles.

Capabilities

Compared to ambient-temperature applications, extreme operating environments require advanced material manufacturing, device fabrication, and corresponding analysis. NREL and project partners offer a variety of capabilities to support this work.

Materials Science Technologies

Related to material synthesis and characterization, various materials science technologies are being leveraged at NREL. Material synthesis would involve both high-quality growth methods such as molecular beam epitaxy for gallium oxide, and other methods for novel contact materials. NREL's state-of-the-art measurement facilities are being used to characterize single crystals manufactured at Luxium Technologies, such as high-resolution and correlative microscopy, secondary ion mass spectrometry and so on, with a goal to perform advanced defect characterization.

Learn more about NREL's materials science research.

Device Fabrication and Validation

The team is working to fabricate gallium oxide-based electronic devices and measure their performance as a function of temperature and mechanical stress using NREL's facilities. Complementary electronic devices characterization capabilities at the Colorado School of Mines will be used to evaluate impact of temperature and corrosive environments on the device performance and reliability.

Modeling and Simulation

A comprehensive computational simulation effort will be conducted including:

- First principal stability, defect, and interface calculations

- Electro-thermal and thermo-mechanical device modeling

- Techno-economic analysis of wafers manufacturing cost.

Partners

This project combines knowledge from academia, industry, and national laboratories. Led by NREL, this project includes the expertise of the Metallurgical and Materials Engineering Department at the Colorado School of Mines and Luxium Technologies, a company with crystal growth facilities. These partnerships leverage several diverse backgrounds in oxide electronic components:

- NREL's core competence oxide semiconductor materials and novel electronic devices

- Luxium Technologies' experience with gallium oxide single crystal wafer manufacturing

- Colorado School of Mines expertise in high-temperature measurements of oxide ionic devices.

Publications

Projected Cost of Gallium Oxide Wafers From Edge-Defined Film-Fed Crystal Growth, Crystal Growth & Design (2022)

Gallium Oxide Heterojunction Diodes for Improved High-Temperature Performance, arXiv:2204.00112 (2022)

Computational Fermi Level Engineering and Doping-Type Conversion of Mg:Ga2O3 via Three-Step Synthesis Process, Journal of Applied Physics (2021)

Performance and Reliability of β-Ga2O3 Schottky Barrier Diodes at High Temperature, Journal of Vacuum Science and Technology A (2021)

Growth and Characterization of Homoepitaxial β-Ga2O3 Layers, Journal of Physics D: Applied Physics (2020)

How Much Will Gallium Oxide Power Electronics Cost?, Joule Volume 3 (2019)

Contact

Share