Distributed Embedded Energy Converter Technologies

NLR is researching and developing an underexplored technology domain for marine energy: distributed embedded energy converter technologies (DEEC-Tec).

DEEC-Tec is a new kind of marine energy technology that distinguishes itself through the use of many small DEECs that are assembled to form DEEC-Tec metamaterials. These metamaterials, in turn, are used to create overall larger structures for the harvesting and conversion of marine energy, like one developed by NLR (now patented).

In this way, the DEEC-Tec domain can be viewed at three technology levels:

Individual DEEC Example

Technology Level 1: An individual DEEC is a relatively small energy transducer (often less than a few centimeters) that converts one or more forms of energy into another and serves as a structural mechanism, providing one or more methods to join or interconnect with other DEECs to form a DEEC-Tec metamaterial.

- Individual small DEECs

- DEEC-Tec metamaterials—essentially,

pseudo-material frameworks made from the interconnection/combination of many DEECs - Larger, complete marine energy harvesting-converting structures made from

DEEC-Tec metamaterials.

Explore an overview of how DEEC-Tecs work.

Technology Level 1: An individual DEEC is often no more than a few centimeters long and acts as both energy transducer and structural mechanism. As an energy transducer, a DEEC leverages at least one physical phenomenon to convert external sources of energy into electricity. As a structural mechanism, an individual DEEC houses or is part of the energy transducer and also enables interconnection with other DEECs.

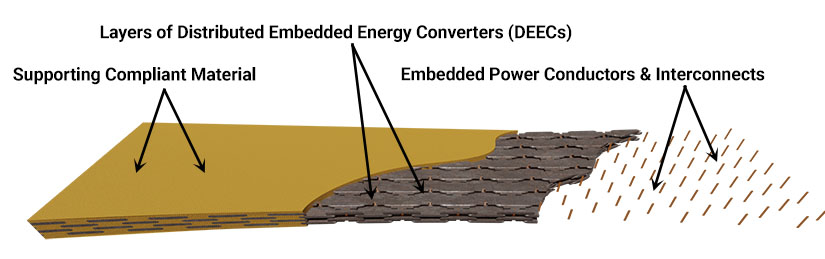

Technology Level 2: DEEC-Tec metamaterials are aggregations and integrations of many DEECs. DEEC-Tec metamaterials are the general building blocks for a structure that can harness and convert marine energy. DEEC-Tec metamaterials could include combinations of DEEC types, combined in different ways (such as layers, latices, or embedded in substrates).

DEEC-Tec Metamaterial Example

Technology Level 2: This sample volume illustrates the basic use of individual DEECs to create a DEEC-Tec metamaterial. The cut-outs expose the constituent components of a generic DEEC-Tec metamaterial. To the left, all constituent components are present. In the middle, the supporting compliant material framework is removed. To the right, both the supporting compliant framework and the individual DEECs are removed. This shows how DEECs combine to create the structural framework of a DEEC-Tec metamaterial and give it its specific properties and characteristics.

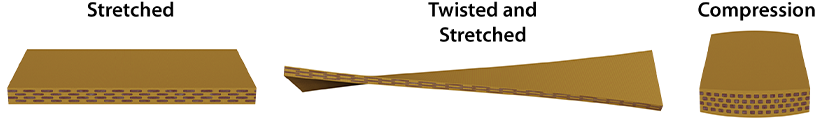

DEEC-Tec Metamaterial Deformation Examples

Technology Level 2: DEEC-Tec metamaterial samples are dynamically deformed—by stretching, twisting and stretching, or compression—by some external source of energy to generate other forms of energy, including electricity.

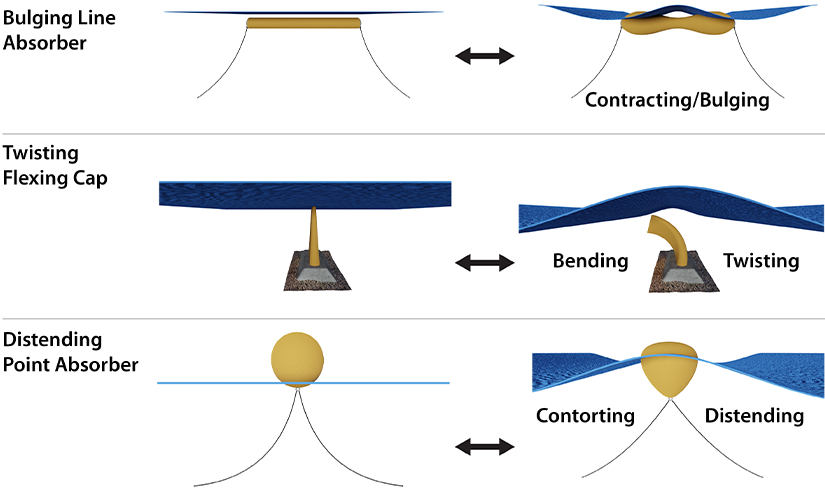

Technology Level 3: A DEEC-Tec-based ocean wave energy converter is an example of an energy harnessing/converting structure made of DEEC-Tec metamaterials. DEEC-Tec-based wave energy converters have two defining characteristics:

- Topology, which describes its form and shape

- Morphology, which describes its stiffness, hysteresis, plasticity, and other kinds of deformation.

DEEC-Tec-Based Ocean Wave Energy Converter Examples

These illustrations show how DEEC-Tec-based ocean wave energy converters (undeformed on the left as yellow shapes moored via black lines to the seafloor) can deform (right) to harness and convert energy. The bulging line absorber (top) bulges and contracts as ocean wave crests and troughs pass by. The bottom fixed surging flexWEC (middle) twists and flexes with the movement of successive surging ocean waves. The contorting point absorber (bottom) distends and contorts as waves move around it. Note that these examples do not represent all possible forms of ocean wave energy conversion via DEEC-Tec and the technology's applications for marine energy.

Activities

NLR is actively exploring several kinds of DEEC-Tec-based marine energy designs.

Hexagonal Distributed Embedded Energy Converters

NLR is developing its own, in-house, distributed embedded energy converter: Hexagonal

Distributed

Embedded Energy Converters, also known as HexDEECs. Explore an overview of HexDEECs.

Structured Innovation

NLR develops and supports structured processes for innovating DEEC-Tec-based designs and aims to deliver seedling concepts to the broader marine energy community. See WaveSPARC.

Material Development

NLR has extensive experience in developing materials for both FMDEC structures and embedded distributed energy converters. This experience, to name of few, leverages techniques ranging from upcycling of used polymers to the development of novel new elastomer electrodes.

Co-Design for Distributed Embedded Energy Converter Technology Converters

NLR is familiar with and has the experience necessary for the co-design of DEEC-Tec-based ocean wave energy converters. Inherent in their nature, DEEC-Tec-based converters require the co-design and concurrent engineering of, at minimum:

- Their compliant structures’ forms

- Their embedded distributed energy converters (the individual energy transducers)

- Their active control power electronics systems and strategies.

Evaluating and Prototyping Distributed Embedded Energy Converter Technology Converters

NLR develops the evaluation tools (e.g., technology performance-level assessments and numerical modeling tools) needed to characterize and assess DEEC-Tec concepts, aiming for a greater understanding and appreciation of the technology's optimal and realistic possibilities.

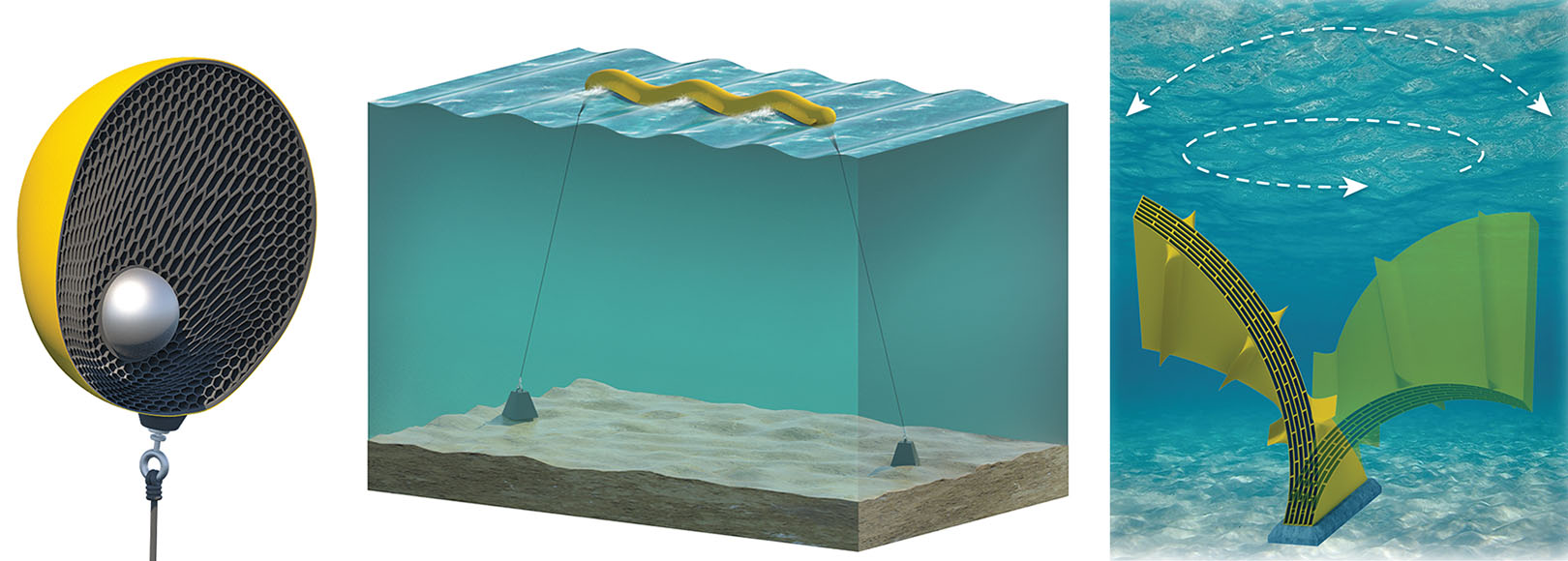

Illustrations of three plausible flexWEC concept archetypes—DEEC-Tec structures converting ocean wave energy into, for example, electricity. Left: Flexible hull inertial point absorber. Center: Flexible line absorber. Right: Flexing bottom-fixed ocean energy converter. Illustrations by Besiki Kazaishvili, National Laboratory of the Rockies

Technology Characteristics

NLR develops the evaluation tools (e.g., technology performance-level assessments and numerical modeling tools) needed to characterize and assess DEEC-Tec concepts, aiming toward a greater understanding and appreciation of the technology's possibilities:

- Broad-banded ocean wave energy absorption: Many modes of motion make this absorption

possible.

- Intrinsic redundant energy converter systems: Numerous interlaced small transducers

(distributed embedded energy converters) provide mechanical redundancy and robustness

(i.e., failure of some transducers need not mean failure of the overall flexWEC).

- Relatively low material procurement and assembly costs: Predominant materials are

polymers that are commonplace and can be fabricated with well-established, roll-to-roll

assembly practices, for example.

- Simple deployment and survival mechanisms: Most archetypes can easily be rolled up,

packaged, and stowed, when need be, for deployment and ocean storm avoidance.

- Reduced maintenance schedules: The distributed embedded energy converters within a

DEEC-Tec structure can also act as sensors throughout that entire structure. The need

for maintenance, therefore, can be handled in real time, based on the information

those transducers are sending to monitors.

- Near-continuous structural control and adaptation: Actively engaging nearly every

distributed embedded energy converter via power electronic control systems allowing

them to act, therefore, as either a generator (damping structural deformation), or

an actuator (energizing structural deformation), thereby enabling the alteration of

a DEEC-Tec structure’s form in real time.

- Unique and highly impactful opportunities for co-design: For example, conceptualizing a DEEC-Tec structure’s form and flexible characteristics can occur directly alongside the development of the structure’s active control systems and manufacturing requirements.

Challenges

Challenges associated with the DEEC-Tec domain include proper material(s) design for fatigue minimization, optimal geometry composition, and power conversion efficiencies as well as individual transducer unit design and embedment configurations.

With the broad scope of design options (e.g., co-designing for the development of DEEC-Tec geometry, transducer arrangements, and active control strategies), there are many reasons to be optimistic about resolving these DEEC-Tec challenges.

Publications and Patents

Numerical Methods To Evaluate Hyperelastic Transducers: Hexagonal Distributed Embedded Energy Converters, Energies (2023)

Distributed Embedded Energy Converter Technologies for Marine Renewable Energy: A Technical Report, NLR Technical Report (2023)

Hexagonal Distributed Embedded Energy Converters (HexDEECs), NLR Poster (2022)

Flexible Wave Energy Converter, U.S. Patent Number 11,401,910 B2.

WBS: 2.2.1.407 Flexible Wave Energy Converters (FlexWEC), U.S. Department of Energy Water Power Technologies Office Presentation (2022)

Distributed Embedded Energy Converters for Ocean Wave Energy Harvesting: Enabling a Domain of Transformative Technologies, NLR Presentation (2021)

Prototype and Codesign of Nascent Flexible Wave Energy Converter Concepts, NLR Presentation (2021)

Internal Report on Evaluation of Cost and Performance Drivers: Key Cost and Performance Drivers Identified and Approximately Quantified, NLR Technical Report (2019)

Contact

Share

Last Updated Dec. 31, 2025