Wave Energy Devices Will Soon Head to New Testing Facility—But They Need Something First

New Study Identifies Cost-Effective Options To Tether Devices to Ocean Floor

Which is cheaper: a semi-taut spread or a catenary weight-float?

No, this is not the start of a sphinx’s riddle. But that question—and others like it—did launch a recent study on mooring systems, the anchor-line combinations that keep ships, buoys, and other floating objects from drifting away on the waves. The goal of the study was to assess performance and cost tradeoffs for mooring systems, including, potentially, the sci-fi-sounding semi-taut spread and catenary weight-float, for a new wave energy test site.

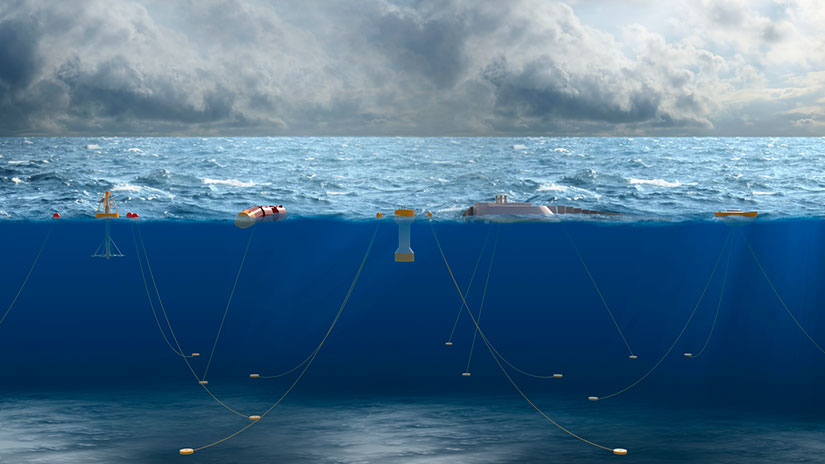

If this still seems like a sphinx’s riddle, here is why this cost conundrum matters: In 2025, the new PacWave South Test Site is expected to open its berths to wave energy technology developers for the first time. There, just off the Oregon coast, developers will be able to test their promising prototypes in actual ocean waves, an essential step to determine whether these devices can weather a rambunctious ocean. But developers need one crucial component to run such tests: They need mooring systems.

“The mooring systems’ main goal is to keep the device where you want it and not let it float away or bump into anything else,” said Stein Housner, a naval architect and marine engineer at the National Renewable Energy Laboratory (NREL) and one of the authors of the WPTO-funded study. “The question was, would it be beneficial for PacWave to own mooring components or to have developers design and acquire them?”

That question might sound simple, but it is not. No two wave energy converters—the devices that turn ocean waves into electricity—are the same. That means no single mooring system would easily integrate with every prototype that tests at PacWave. Some wave energy converters are as small as buoys. Others are as big as floatplanes designed to land on water and require more than one tether. And some need a tough chain while others perform better with a pliable rope that lets them bob in the waves.

If each company buys its own mooring system, customized to suit its bespoke design, that would significantly increase the test’s cost. “If a technology developer is only testing a device for a couple months, why spend all that money for just one test?” Housner said.

But if PacWave can identify a few generic mooring systems that could serve most—if not all—wave energy converters, the facility could buy in bulk and save everyone money. So, Housner, along with study co-author Senu Sirnivas, a mechanical engineer at NREL, set out to determine what kind of generic mooring systems could get the job done and how much those systems might cost.

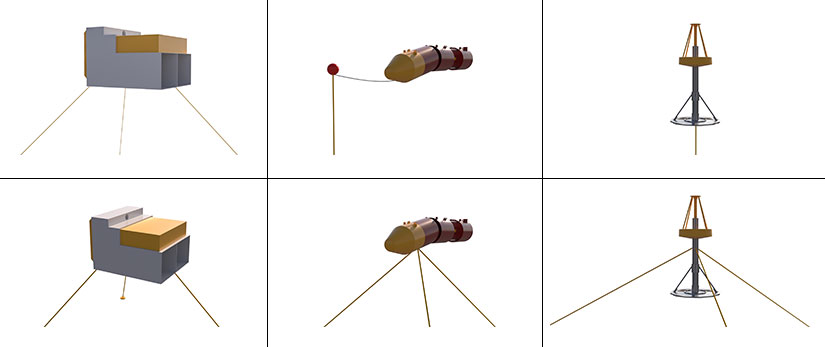

But first, Housner and Sirnivas’ colleagues at the Pacific Northwest National Laboratory put together a list of all the potential wave energy devices that could test their mettle at PacWave. Based on that, the team categorized the devices into three main types: point absorbers (which look like pistons that have a buoyant bit that bobs in the waves), attenuators (which are snake-like and, essentially, ride the waves), and oscillating water columns (which are big chambers that harness wave energy as water surges in and out).

Based on those three wave energy device types, Housner and Sirnivas concocted a list of potential mooring systems that could work well for each. They came up with 43 different mooring designs that use different combinations of materials (like metal chain versus synthetic or wire rope), diameters, lengths, footprints, and more.

“Then the question was, how do we determine the total cost of buying mooring system components for PacWave?” Housner said. “Do we say, ‘Order five of these mooring lines from X company,’ and that’s all you need? How do you then select how many of each mooring system to acquire for devices that may or may not be tested at PacWave?”

To solve this puzzle, Housner and Sirnivas considered how the already-established U.S. Navy Wave Energy Test Site in Hawaii handled its mooring systems. “The mooring system was preinstalled in the water,” Sirnivas said. “So, people can come in and hook up to the existing system that’s already there.”

But leaving mooring systems submerged in salty, energetic waters can cause them to degrade quickly. Instead, Sirnivas and Housner recommend that PacWave purchase mooring components and store them on shore. When a device finishes its ocean trial, PacWave would then retain the mooring system components. Eventually, they could accrue a diverse enough set to serve almost any wave energy device.

“It’s like a menu,” Housner said.

Although wave energy devices come in many shapes and sizes, most come in one of the three flavors pictured here: oscillating water column (left), attenuator (middle), and point absorber (right). For their mooring study, the researchers identified generic systems that could serve all three. Illustrations by Josh Bauer, NREL

Once Housner and Sirnivas identified the most practical way to purchase the mooring systems, they could finally track down the most cost-effective versions of those systems. Based on those estimates, Housner said, if PacWave bought one mooring system for each of their four berths—the designated areas where devices can anchor without bumping into one another—that would likely cost around $2 million. If they bought enough mooring systems to fit as many wave energy devices as their waters could hold, that might come to around $9 to $10 million, but the site does not need to do that—at least not yet.

Once PacWave South opens, likely in late 2024, the site will be the first grid-connected wave energy test facility that is both pre-permitted, meaning developers won’t need to acquire a separate permit, and accredited. The first wave energy devices—and their mooring systems—are expected to hit the water in 2025.

(By the way, if you guessed the semi-taut spread is cheaper, you were right. The sphinx will let you pass.)

The PacWave Anchoring and Mooring Study is intended to offer guidance to the U.S. Department of Energy’s Water Power Technologies Office, the PacWave team at Oregon State University, and wave energy developers that plan to pursue ocean trials at the PacWave wave energy test site.

Want more details on moorings? Check out the full PacWave Anchoring and Mooring Study. And subscribe to the NREL water power newsletter, The Current, to make sure you do not miss a water power update.

Last Updated May 28, 2025