Coming Soon to a Grid Near You: Clean Energy (Batteries Not Included)

How Recycling Batteries Could Help Us Keep Up with the Decarbonization Race

Maybe you toss your spent batteries into a jar on your kitchen counter. Or maybe it is a corner of a junk drawer that slowly accumulates AA and D cells after your TV remotes, smoke alarms, and clocks drain their power. And maybe, if you are especially concerned about chemicals leaching into water supplies or trash fires, you are one of the few who sends these dormant metals to a recycling center.

If you are among the latter, kudos to you. But there are more batteries lurking in your life. Lithium-ion batteries run our smartphones and laptops, electric toothbrushes, and electric cars. Even if you do not recycle those potent batteries, the United States—and the world—will have to.

“We’re going to need a lot of batteries,” said Paul Gasper, a staff scientist for the Electrochemical Energy Storage group at the National Renewable Energy Laboratory (NREL). “We’re going to need a lot of them for both vehicles as well as storing energy from renewable generation methods, like solar or wind.”

As the country decarbonizes its electric grid, as well as all cars, trucks, trains, and even airplanes, Americans will need a battery of batteries to electrify those vehicles and store power when the sun does not shine and the winds do not blow.

But mining more metals to manufacture more batteries consumes huge amounts of energy and emits greenhouse gases. Plus, the Earth simply does not contain enough accessible metal for us to mine. We need another way to amass our energy storage cornucopia—one that provides cheaper, more powerful batteries with fewer environmental costs.

And that is exactly what a team of NREL researchers are investigating. Along with collaborators in the U.S. Department of Energy’s new ReCell Center, Gasper and colleagues are working to improve how the country manufactures, recycles, and reuses these powerful materials.

In short, they are rebuilding the battery.

“The number of batteries that we’re currently producing globally is growing very rapidly every year,” Gasper said. “We really need to make sure that those batteries are safe and last a long time and that we recover those valuable resources at the end.”

But recycling batteries is not a simple task.

Historically, the process took one of two forms. Spent batteries were either melted down in a furnace or dissolved in acid. The first option wastes a lot of energy, and neither option recovers all the precious materials.

Not all lithium-ion batteries are the same, either. A phone needs a different battery than an electric car. And each cell contains layers upon layers of metals, including lithium, as well as nickel, cobalt, and manganese, which do not always degrade in the same way. Some batteries can be crushed safely, but others cannot. Each defunct cell is its own recycling puzzle.

“The initial strategies that were used to recycle batteries are a bit more challenging when you think about the scale of the problem we’re dealing with,” said Kae Fink, a researcher in NREL’s Energy Conversion and Storage Systems Center.

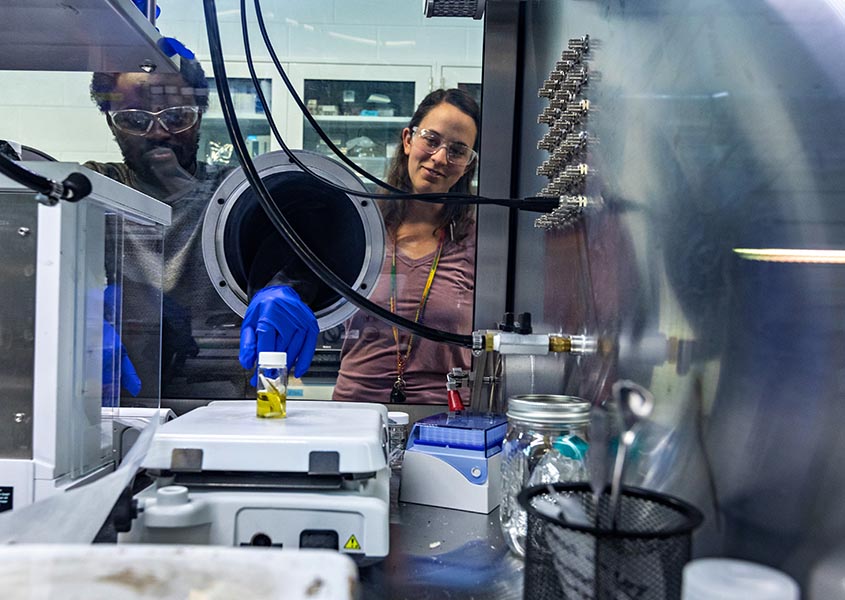

Fink and Gasper are investigating a relatively new way to recycle batteries, called direct recycling. With direct recycling, they can deconstruct a battery without breaking any of the metals’ chemical structures. This gentler process could help recover more materials compared to the previous, more destructive recycling methods.

Gasper is also using machine learning to rapidly examine used batteries and assess their health. With that data, he can then triage those spent cells. Healthy cells, for example, could be reused in new applications; somewhat healthy cells could undergo direct recycling to extract their electrode materials; but the unhealthy cells might be unsalvageable without the original furnace or acid method.

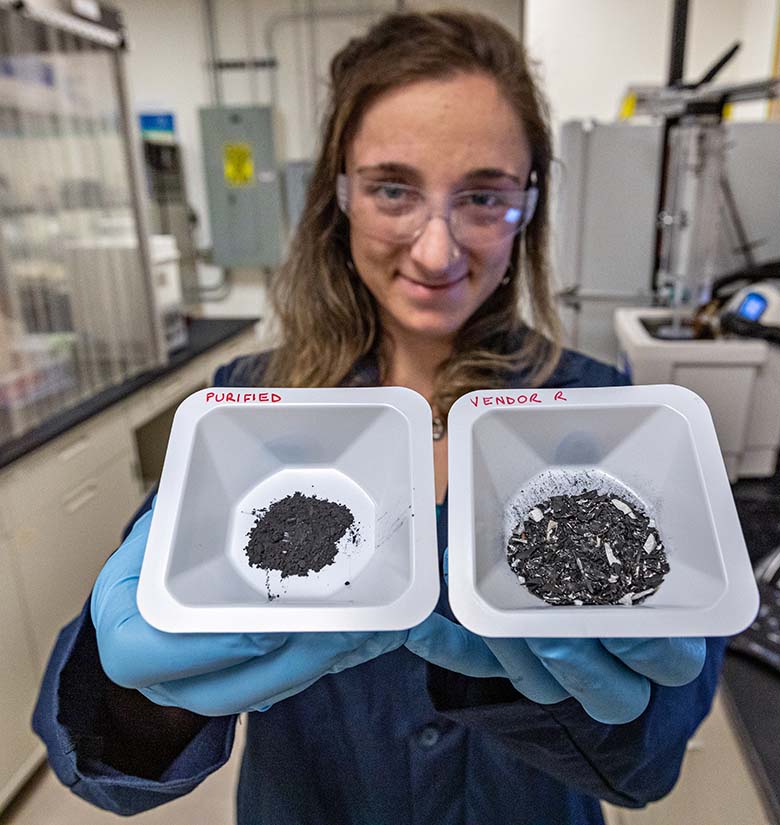

But Fink wants to do more than just recycle batteries. She wants to upcycle them.

“We’re thinking about how we can kind of skip a step or jump the gap and actually create a better engineered material from the recycled product that is even more advanced and can go into next-generation batteries,” she said.

Upcycling could give us more for less—more battery power for less money, materials, and energy.

And the next generation of batteries could depend less on lithium, too. Some future batteries could run on sulfur, which is more abundant and easier to get than lithium. But sulfur comes with its own challenges. Because the material reacts to oxygen, sulfur-based batteries would need to be manufactured in oxygen-free environments.

“How do you deal with that?” said Matt Keyser, senior researcher in the electrochemical energy storage group at NREL.

Keyser and his team are also exploring other potential new designs, like solid-state batteries. Solid-state batteries, which use solid instead of liquid electrodes and electrolytes, could pack more power into smaller cells, enabling electric vehicles to travel farther between charging points, and potentially lower their cost, too.

Kae Fink, NREL

But, even if Keyser calls solid-state batteries “the new revolution of the lithium-ion batteries,” these, too, are not challenge-free. They need high pressure to operate. Right now, NREL scientists are designing new manufacturing techniques to reduce that pressure demand from 10,000 PSI—or pounds of pressure per square inch—to 50 PSI (a car tire averages about 36 PSI).

“It’s a big difference,” Keyser said. “The auto manufacturers aren’t going to accept 10,000 PSI. There’s no way that they put that in a vehicle.”

No one would buy a vehicle that could go pop like a shaken can of soda.

If Keyser, Fink, Gasper, and the ReCell Center community succeed at building a new generation of safe, longer lasting, and cheaper batteries, that energy storage battalion could not only help make electronics, including electric vehicles, more affordable and accessible; they could also help the country build a reliable 100% clean energy grid.

“Everyone wants their cell phone to last longer. Everyone wants their tablet to last longer,” Keyser said.

Everyone wants their planet to last longer, too.

Learn more about how NREL researchers are remaking batteries and other energy storage technologies to manufacture a 100% clean energy future and spearheading battery recycling solutions with holistic and forward-thinking research.

Last Updated May 28, 2025