Better Components Can Boost Range and Efficiency of Next-Gen Sustainable Aircraft

The future of sustainable aviation is at our fingertips, with new technologies providing actionable pathways for lowering greenhouse gas emissions for aircraft travel. Advancements in electrification and fueling are one exciting aspect, but research at the National Renewable Energy Laboratory (NREL) goes beyond power generation with a holistic approach to optimize energy use throughout the entire system design.

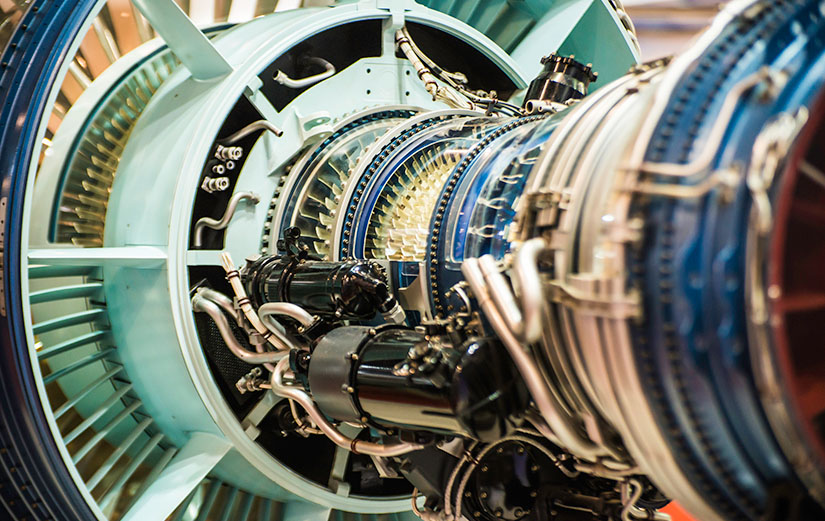

Aircraft rely heavily on advanced power electronics to distribute the proper amount and type of power between system components such as batteries, inverters, converters, chargers, and electric machines. NREL’s advanced power electronics and electric machines research supports the development of innovative lightweight and ultraefficient electric motors, propulsion systems, and thermal management. Industry partnerships, including an ongoing collaboration with General Electric, are already helping aircraft engine manufacturers meet their goals.

“NREL research aims to decrease costs, reduce component footprints, and improve vehicle performance, reliability, and efficiency,” said NREL Senior Researcher Sreekant Narumanchi. “These component designs can be incorporated into various applications—from commercial aviation to smaller takeoff and landing vehicles. In addition, our findings can help optimize next-generation aircraft, including those powered by electricity, hydrogen, or alternative fuels.”

As part of this focus on sustainable aviation, NREL is currently supporting two projects within the Department of Energy’s (DOE’s) ARPA-E Aviation-class Synergistically Cooled Electric-motors with iNtegrated Drivers (ASCEND) program to develop high-efficiency electric powertrains, motor drives, inverter modules, and thermal management systems for sustainable aviation.

The first project, led by the General Electric Global Research Center, will design a 2-MW fully integrated all-electric aircraft powertrain and demonstrate a 350-kW lab-scale prototype to enable zero-carbon-emission narrow-body commercial aircraft with all-electric propulsion. The second project, led by Marquette University, also focuses on building high-power-density motors and power electronics for aviation.

“ARPA-E has proven itself to be a pioneer in many areas, and the ASCEND program is a good example,” Narumanchi said. “This is one of the first DOE-funded programs related to electrified components in the context of aviation. We are excited to collaborate with many high-caliber colleagues across the industry and academia.”

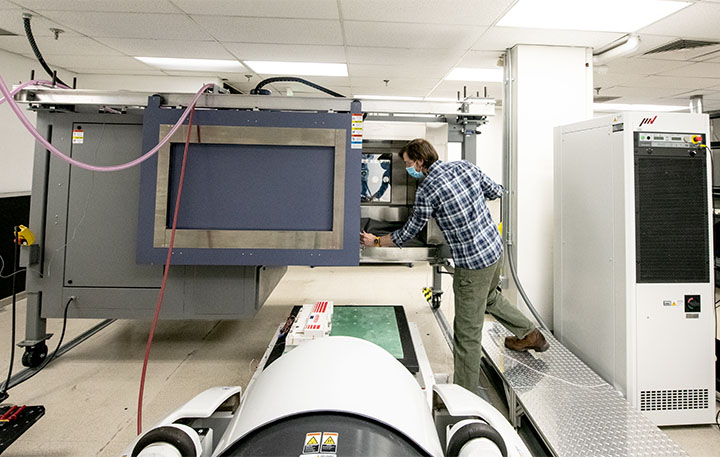

Both projects explore a unique approach to developing electric motors and integrated electric-drive systems for hybrid-electric aircraft by reducing system weight and volume to support increased range and efficiency—all without sacrificing aircraft safety and reliability. NREL’s support for these projects includes thermal management modeling, analysis, and characterization of the advanced cooling concepts and inverter components, alongside thermomechanical and reliability design, and techno-economic analysis for various power electronics, electric motor, and integrated electric drive components.

Unique System Specifications for Sky-Bound Vehicles

As with all systems, an aircraft is greater than the sum of its parts, and NREL researchers are committed to optimizing system-wide integration alongside individual component innovations. Although these systems have many similarities with the powertrains found in on-road vehicles, aircraft designs present different challenges.

“Weight is critical in these designs,” Narumanchi said. “We are looking to achieve the highest possible functionality with the lowest possible weight. As a result, our team is evaluating new materials, such as lightweight heat exchangers, supercritical carbon dioxide coolant, and possibly others.”

In addition, components used in aircraft must exhibit exceptional reliability to meet the significant flying time expected of commercial aviation. NREL researchers perform extensive reliability modeling to ensure new subcomponent designs meet this challenge. Furthermore, system-level evaluations ensure that the integrated electric drive system—including the electric motor, power electronics, and the thermal management system—meet sensitive and demanding aviation industry standards.

Aviation is among the most difficult transportation sectors to decarbonize, but NREL is up to the task. With substantial experimentation, hardware, modeling, and analysis capabilities, researchers are well equipped to meet challenges that exist within aviation.

Learn more about NREL’s cross-cutting sustainable aviation and transportation and mobility research.

Last Updated May 28, 2025