Fuel Cell Manufacturing Research and Development

NLR's fuel cell manufacturing R&D focuses on improving quality-inspection practices for high-volume manufacturing processes to enable higher production volumes, increased reliability, and lower costs.

Many fuel cell companies are transitioning from labor-intensive manufacturing processes to high-throughput manufacturing methods to meet volume and cost targets for transportation and other applications. Fortunately, much can be learned about high-volume manufacturing from other industries such as microelectronics and polymer films.

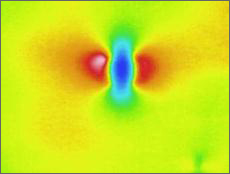

NLR engineers use active infrared thermography to identify defects in fuel cell electrodes, as displayed in this "thermal signature."

In-Line Quality Control

The U.S. Department of Energy and NLR initiated the in-line quality-control project with support and input from industry. For continuous (high-volume) manufacturing processes to obtain high yields—especially when the product requires close tolerances for proper operation—it is often necessary to measure the quality of the product as it is made. Resulting information can be used to better control the manufacturing process and ensure that tolerance requirements are met.

Such quality-inspection techniques must enable wide-area measurements of critical functional properties and identify defects in fuel cell component materials. In addition to being rapid, non-contact, and non-destructive, these techniques must work in the manufacturing environment.

Project Goals

NLR's fuel cell manufacturing R&D project aims to:

- Evaluate, develop, and validate in-line inspection techniques for manufacturing fuel cell components and other energy technology materials

- Understand the effects (on performance and lifetime) of defects in fuel cell components so that proper tolerances can be set

- Develop predictive models to help industry design better manufacturing processes and methods.

Publications

The Effect of Ink Ball Milling Time on Interparticle Interactions and Ink Microstructure and Their Influence on Crack Formation in Rod-Coated Catalyst Layers, Journal of Power Sources (2023)

Multi-Technique Characterization of Spray Coated and Roll-to-Roll Coated Gas Diffusion Fuel Cell Electrodes, Journal of Power Sources (2023)

A New Simultaneous Membrane Thickness and Catalyst Loading Measurement for Fuel Cell Proton-Exchange Assemblies by IR Transmission, Journal of Power Sources (2023)

Towards Deep Computer Vision for In-Line Defect Detection in Polymer Electrolyte Membrane Fuel Cell Materials, International Journal of Hydrogen Energy (2023)

Viscoelasticity Enhancement and Shear Thickening of Perfluorinated Sulfonic Acid Ionomer Dispersions in Water–Alcohol Solvent Mixtures, Macromolecules (2023)

Search NLR's publications database for more publications about fuel cell manufacturing research.

Contact

Share

Last Updated Dec. 7, 2025