Industrialized Construction Innovation

NLR's industrialized construction innovation work advances manufacturing techniques to support scalable, cost-effective, and timely solutions to meet the evolving needs of next-generation buildings and energy infrastructure.

As energy demand across the country continues to grow, NLR's industrialized construction innovation team is supporting the construction and deployment of high-performance buildings by integrating advanced manufacturing techniques with optimized construction and design processes. Through methods such as off-site prefabrication, modular construction, and on-site automation, the team is working to streamline construction, reduce costs, and enable faster delivery.

These approaches not only improve energy efficiency and reliability but also help meet the evolving infrastructure needs of communities—especially those in extreme environments—while strengthening the U.S. construction workforce. Through strategies focused on both product and process optimization, the team is working to transform how such complex infrastructure is delivered.

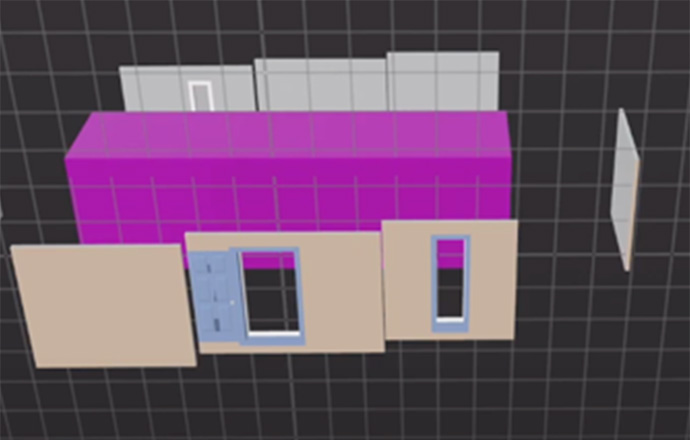

- Product optimization involves designing buildings and infrastructure systems specifically for manufacturing and assembly, making them well suited for quality-controlled, high-speed production using industrialized methods. This approach enables more efficient fabrication and construction of complex systems, ensuring consistency, scalability, and reliability across projects.

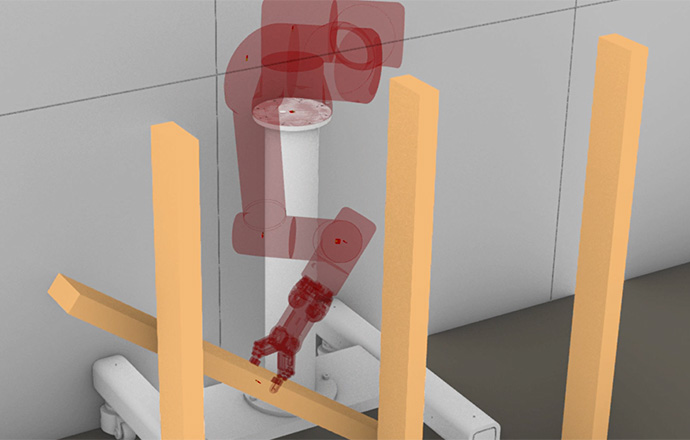

- Process optimization focuses on improving the efficiency of industrialized construction workflows—both off-site in factories and on-site through robotic construction. Advanced tools such as discrete event simulation, digital twins, and time-and-motion studies are employed to model, analyze, and streamline these processes. This data-driven approach enhances productivity, reduces waste, and supports faster, more predictable project delivery.

By integrating advanced manufacturing with optimized design and construction processes, NLR aims to enable scalable, cost-effective, and timely solutions to meet the evolving needs of next-generation buildings and energy infrastructure.

Focus Areas

Design for Manufacturing and Assembly

Utilizing advanced manufacturing and product design strategies to reduce cost and maximize productivity

Discrete Event Simulation

Utilizing process modeling to streamline offsite and onsite construction processes

Building Performance Evaluation

Maximizing performance of modular units through prototype evaluation

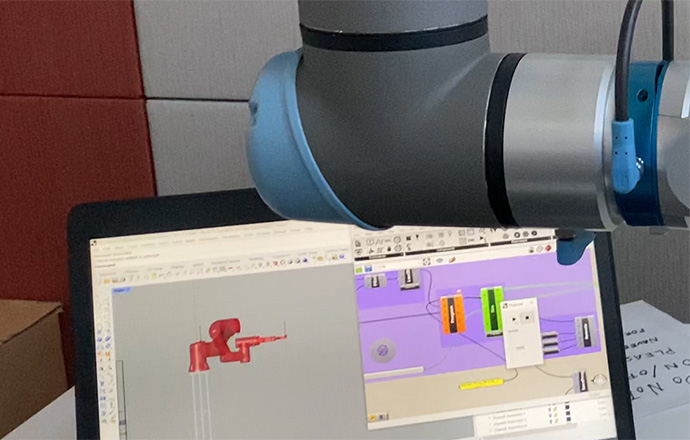

Robotics Software Development

Research and development focused on software development for simulation and control of robotic apparatus for industrialized construction

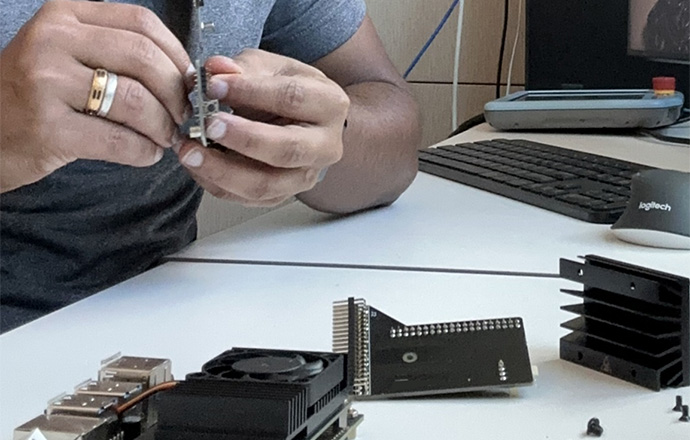

Robotics Hardware Development

Research and development focused on robotic apparatus hardware for industrialized construction

Robotic Level of Autonomy Research and Development

Research and development focused on varying levels of autonomy appropriate for different types of industrialized construction tasks

Robotics Field Evaluation

Research and development focused on field deployment of robotic apparatus for industrialized construction

Field Evaluation

Demonstrating time and performance benefits of industrialized construction solutions by using digital twin representations of products and processes

Field Evaluation in Extreme Environments

Demonstrating time and performance benefits of industrialized construction through evaluation of unitized systems to address unique labor constraints associated with extreme environments

Capabilities

- Insight center for visualizing industrialized construction processes

- High-performance computing for artificial intelligence training of autonomous construction robots

- Machine shop for fabrication of industrialized construction components

- Modular factory pilot line for industrialized construction

- Modular research block for industrialized construction field data collection

- Alaska facility for applied research for communities in extreme environments

Publications

Robotics for Systems Integration in Buildings—Pilot Study of Viable Approaches to Install Hygrothermal and Rigid Electrical Systems, NREL Conference Paper (2024)

Automated Assembly Progress Monitoring in Modular Construction Factories Using Computer Vision-Based Instance Segmentation, American Society of Civil Engineers Conference on Computing in Civil Engineering (2023)

The Energy in Modular Buildings Method: A Guide to Energy-Efficient Design for Industrialized Construction of Modular Buildings, NREL Technical Paper (2022)

Industrialized and Robotic Construction Advances in Terrestrial Construction and Opportunities in Space Construction, NASA Marshall Space Flight Center Tech Talk (2022)

Simulating Off-Site Construction Factories to Deliver Energy Efficient Modular Buildings, The AnyLogic Conference (2021)

View all NREL publications about industrialized construction research.

Contact

Share

Last Updated Dec. 24, 2025