Innovations for Mining, Industry, and Agriculture

NLR develops innovative platforms and microbial systems for energy-intensive industrial processes—such as cement production, mining, agriculture, and heat generation for chemical production—to reduce costs.

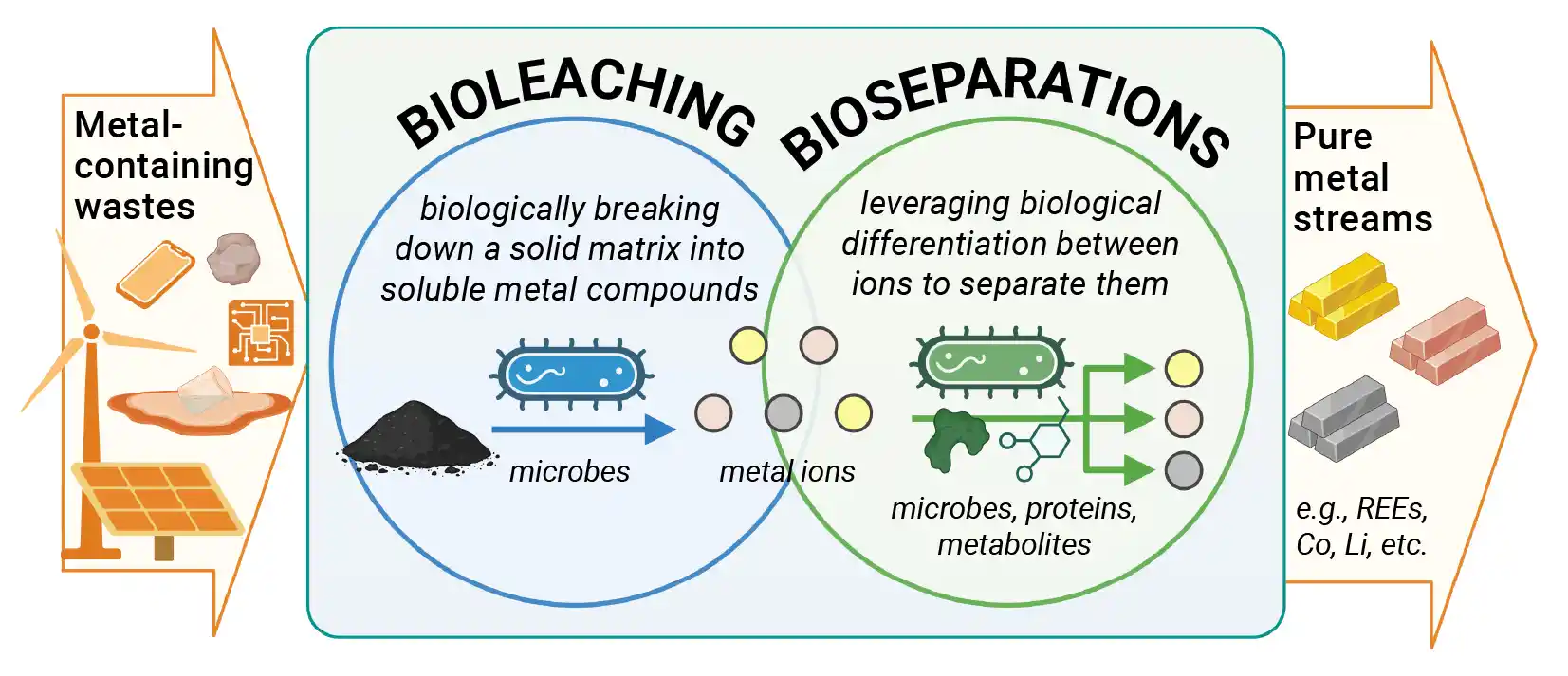

These innovations can provide robust bioleaching of metals in battery recycling, protein-based adsorbents that can concentrate or separate rare-earth elements, biomanufacturing food-quality protein, and biogenic calcium carbonate for high-performance building materials.

Key Capabilities

Our key research capabilities focus on:

- Biohydrometallurgical metal extraction or separations using engineered proteins and microorganisms where energy input and toxic wastes can be reduced

- Production of biogenic calcium carbonate (CaCO3) and high-value co-products from calciferous microalgae to produce Portland limestone cement

- Biomanufacturing of food protein from biogenic waste carbon

- Modeling of inductive thermocatalysis to selectively heat specially designed catalysts that reduce energy consumption in the production of large volume chemicals

- Improvement of nutrient recovery in wastewater treatment.

Note: This video was produced when the laboratory operated as the National Renewable Energy Laboratory (NREL). The laboratory is now the National Laboratory of the Rockies (NLR).

Flagship Projects

Although U.S. virgin metal reserves are limited, unconventional and waste feedstocks represent an untapped but promising resource to secure the nation’s critical mineral supply chains. NLR is developing a suite of bio-enabled technologies to extract ("bioleach") and separate metals from unconventional feedstocks, such as end-of-life electronics, mining wastes, and coal byproducts.

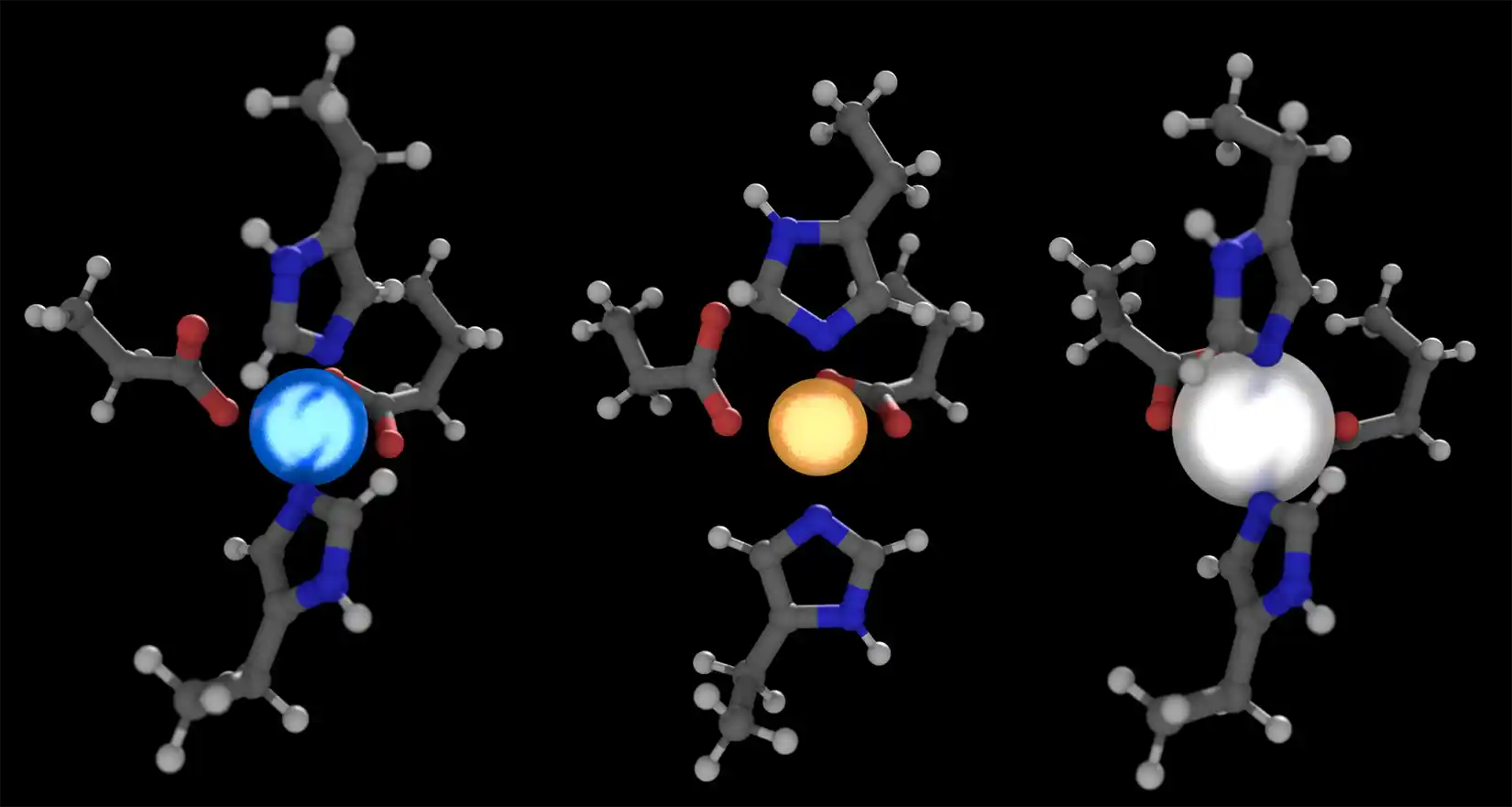

Our work is guided by process modeling, techno-economic analysis, and life cycle assessment, which has emphasized the importance of reducing the intensive chemical and solvent demand needed for today's metal separations. In one example, we have developed a novel chemical resin, which enables efficient extraction of lithium from brine, in collaboration with industry. In another example, we are leveraging computational modeling and machine learning to understand the fundamental principles determining protein–metal selectivity, ultimately toward designing bespoke protein adsorbents that could concentrate or separate target metals in aqueous solutions.

NLR's approaches leverage its bioeconomy interdisciplinary expertise and cutting-edge capabilities in synthetic biology, protein engineering, bioprocess development, separation sciences, computational modeling, and techno-economic and life cycle analysis.

Bioleaching and bioseparations can help recover critical minerals from unconventional feedstocks. Illustration by Allison Werner, NLR

Energy-optimized structures of protein active sites with different metals.

Contacts: Allison Werner and Peter Ciesielski

Cement production accounts for more than 7% of global carbon discharge, most of which is due to calcination of quarried limestone. Use of biogenic CaCO3 derived from calciferous microalgae (coccolithophores) has the potential to drastically reduce the energy intensity of production of Portland limestone cement. Partnering with the University of Colorado, Boulder, University of North Carolina Wilmington, and Minus Materials, NLR is establishing a platform for the production and conversion of coccolithophore-derived CaCO3 and high-value coproducts derived from the biomass organic fraction.

Contact: Mike Guarnieri

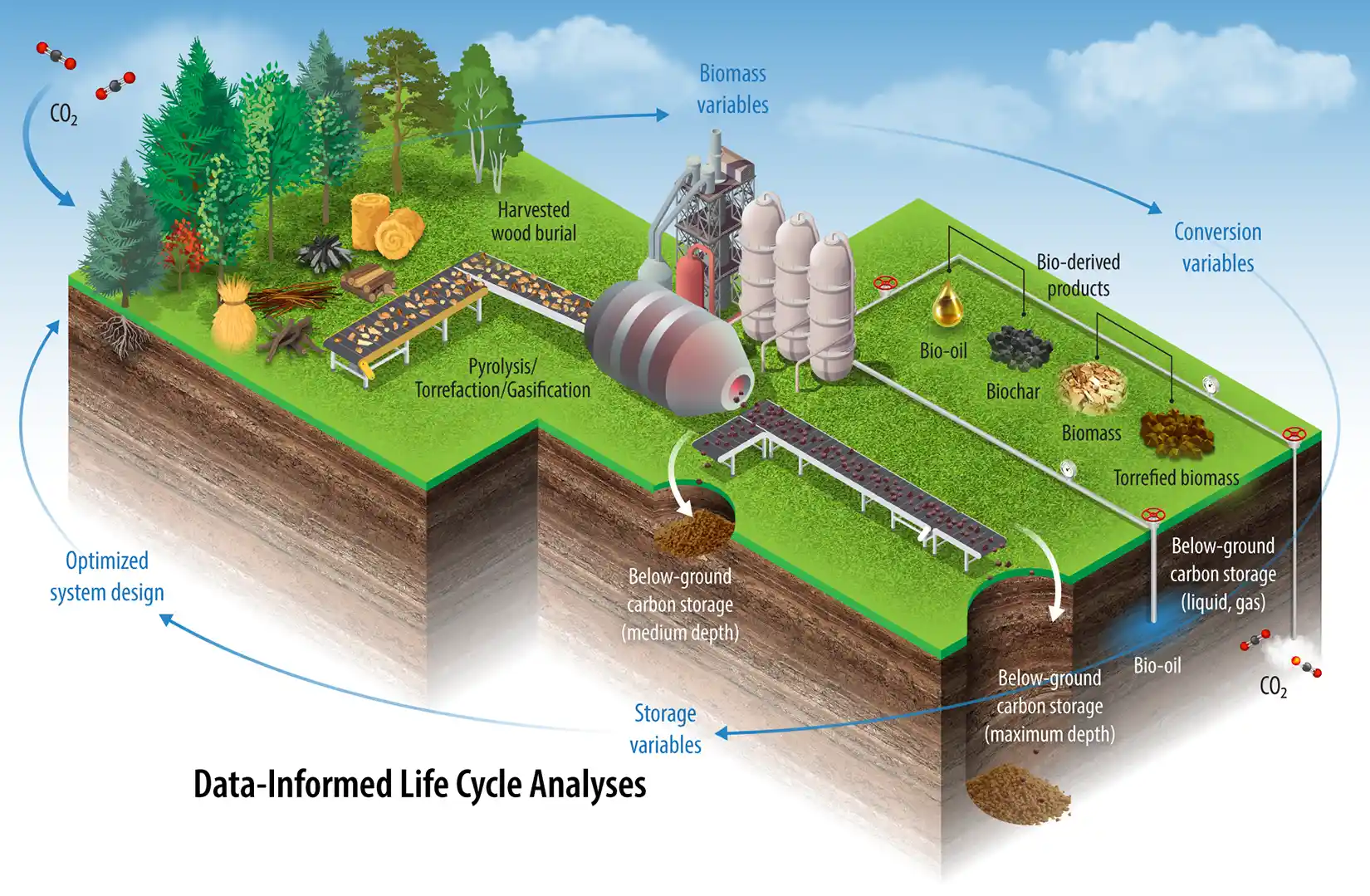

NLR has broad expertise in feedstock sourcing, biomass and bio-product characterization, process knowledge, and process design, as well as life cycle analysis, with dynamic baselines.

Our research addresses scientific knowledge gaps and verification challenges regarding the durability of bio-derived products and conditions to generate critical data for our industry partners.

Through this partnership across the biomass carbon removal and storage (BiCRS) value chain, NLR's vertically integrated project creates a framework using experimental data to develop tools, models and measuring, monitoring, reporting, and verification best practices for research and industrial BiCRS applications.

Illustration by Al Hicks, NLR

Contact: Liz Ware

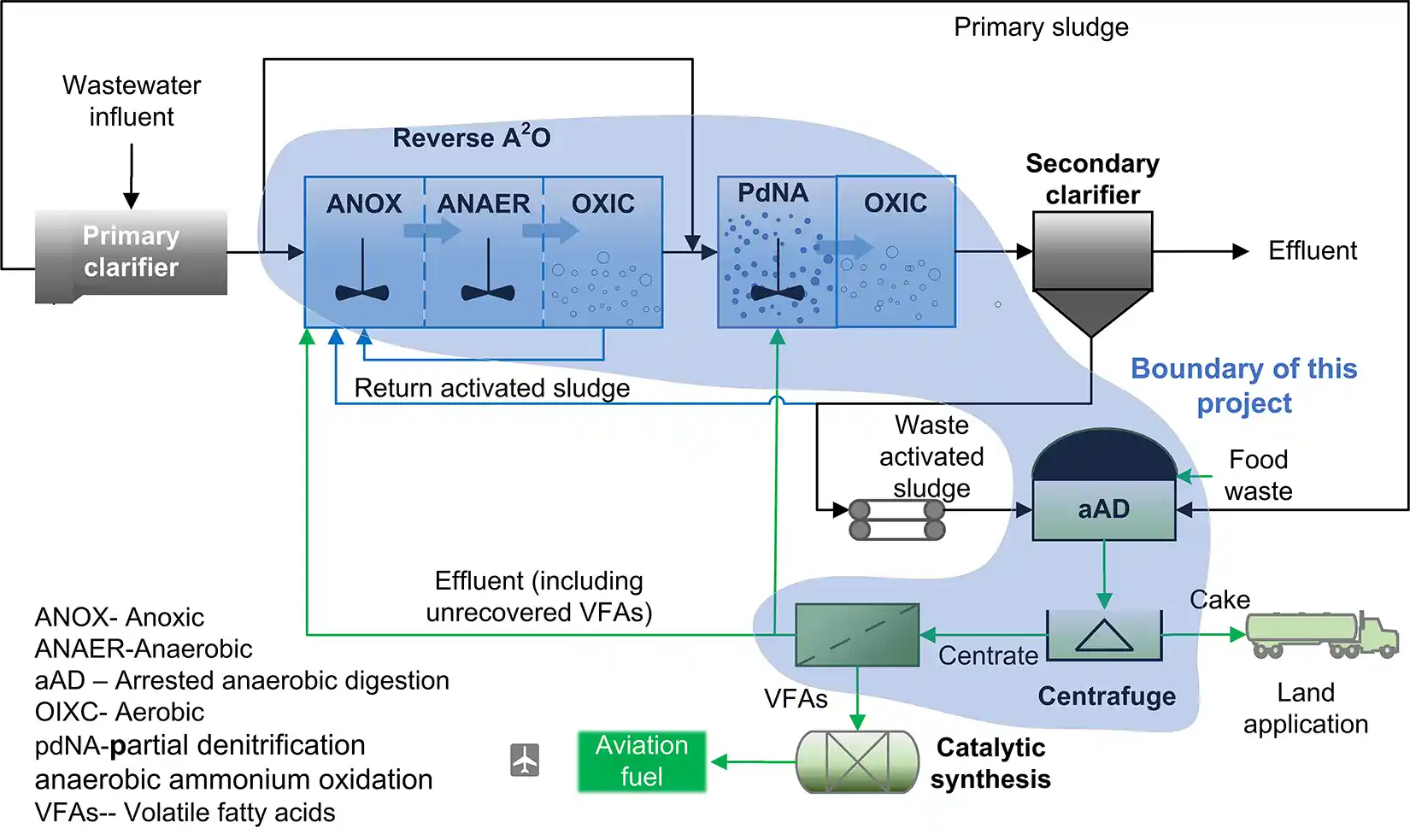

Using a novel approach in water resource recovery facilities (WRRFs), this project aims to enhance WRRFs by implementing an integrated wastewater treatment and resources recovery system through: retrofitting the conventional five-stage Bardenpho basin to reduce aeration and mixing, liquid recirculation demand; developing arrested anaerobic digestion (AAD) and separation technologies to produce volatile fatty acids (VFAs); and recirculating the residual VFAs produced from AAD as a carbon source to improve nutrient removal.

Graphic from the U.S. Department of Energy Industrial Technologies Office

Contact: Violeta Sanchez i Nogue

Significance and Impacts

NLR's novel approaches and breakthroughs in biomanufacturing and biocatalysis are applied across economic sectors to reduce costs while expanding domestic energy production.

Contact

Share

Last Updated Jan. 26, 2026