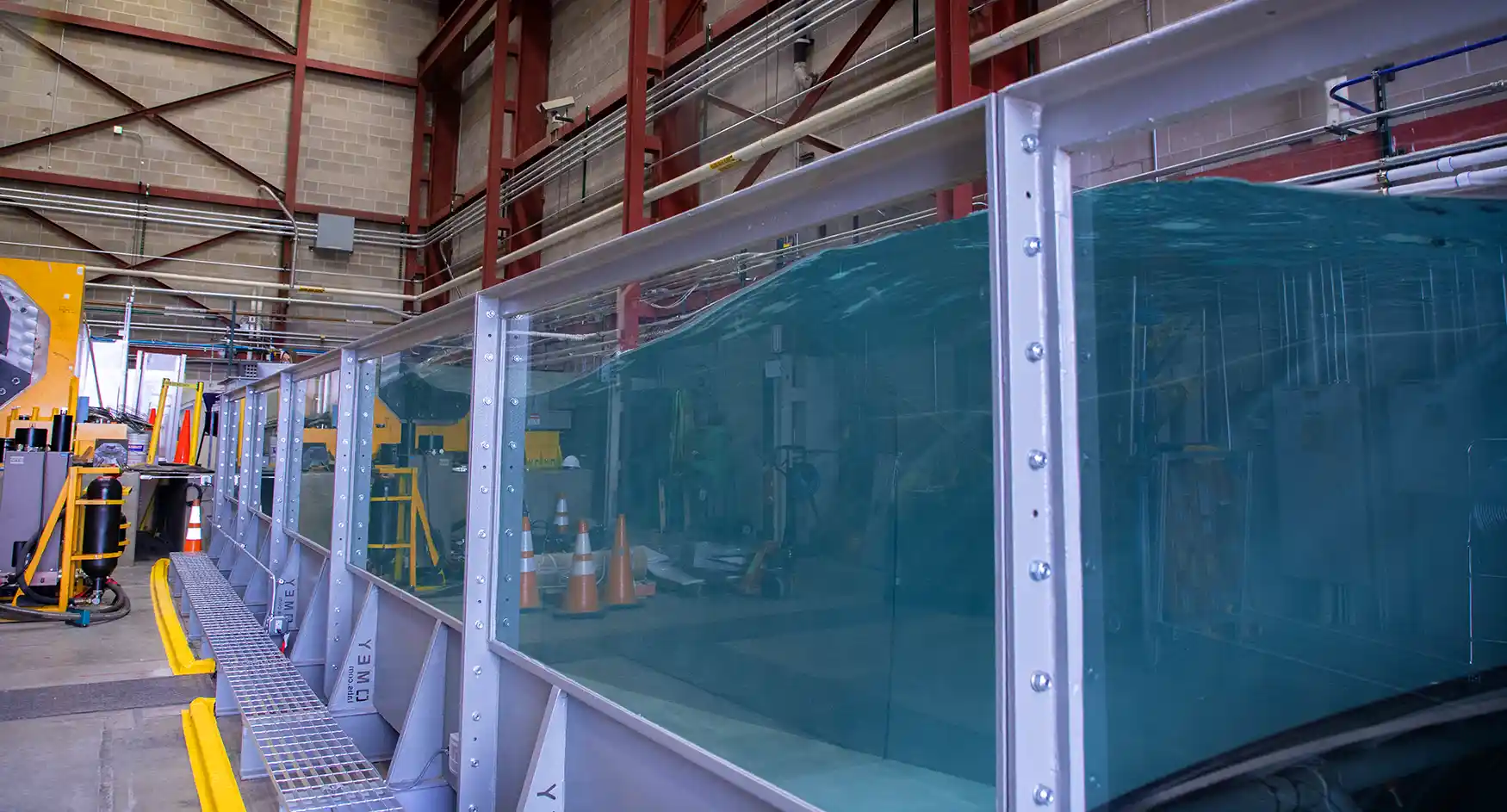

Wave Tank

NLR's wave tank, located in the Sea Wave Environmental Lab (SWEL) at the Flatirons Campus, is an ocean-simulation tool that can validate small- to large-scale wave and tidal energy technologies.

At the Flatirons Campus in Arvada, Colorado, developers working on marine energy devices receive comprehensive support to take their technology from abstract concept to the ocean and, eventually, the market and energy grid.

NLR's engineers and technicians are highly qualified to assist with rapid prototyping and validating technology designs. And SWEL's wave tank can emulate many of the conditions that ocean-bound devices may face at sea. Because open-water tests can come with high costs and risks, technology developers can use the wave tank to validate their small- and large-scale devices in a relatively low-risk environment and ensure they are well-prepared to succeed offshore.

Explore the tank's capabilities and specifications in the following sections or via the NLR wave tank fact sheet.

Capabilities

NLR's wave tank provides a versatile testing environment for marine energy research allowing for wet validation of small-scale devices that are approximately 1/75 the size of a full-scale device. One side of the tank is glass so developers can observe how technology, such as mooring equipment, functions beneath the water's surface.

Combined with NLR's simulation and advanced manufacturing capabilities, SWEL can enable rapid design, prototyping, and validation in one location. Technology developers can manufacture small-scale prototypes using NLR's 3D printers. Then, they can use the wave tank to gather data on how the device performs, make changes based on the results, manufacture a new prototype, and continue to quickly validate and upgrade their design.

Specifications

Wave tank users can access a National Instruments CompactRIO controller and software to precisely control their experiments and specify spectrum type, significant wave height, and wave period.

The OMEY Labs wave tank:

- Features a flap-type, 2D wave generator

- Is 14 meters long, 1.3 meters deep, and 2.5 meters wide

- Holds 13,000 gallons of fresh water

- Generates up to 0.2-meter-amplitude, linear waves at a variety of frequencies (0.5–5 seconds), which is 1:50- to 1:100-scale pitched to North Atlantic seas

- Offers a glass flume wall for external underwater observation and imaging

- Provides a robust mooring system capable of withstanding 500 pounds of hold force

- Has a wave absorber to minimize wave reflection.

The SWEL also has the following additional support instrumentation, which enables more robust device validation:

- Four motion tracking cameras to monitor device dynamics

- Four wireless ocean sensors

- Six resistive wave sensors

- Flow meters

- Accelerometers

- Pressure sensors

- Load cells.

NLR's wave tank allows researchers and developers to generate controlled regular and irregular ocean conditions, evaluate device performance, and rapidly iterate designs to advance water power technologies toward commercialization. Photo by Joe DelNero, National Laboratory of the Rockies

Opportunities for Collaboration

The lab welcomes new collaborations with internal NLR researchers and external developers who aim to validate their technology, integrate technologies, or perform facilities research.

Share

Last Updated Dec. 22, 2025