Pumped Storage Hydropower Cost Model

With NLR's cost model for pumped storage hydropower technologies, researchers and developers can calculate cost and performance for specific development sites.

Photo from Consumers Energy

Pumped storage hydropower (PSH) plants can store large quantities of energy equivalent to 8 or more hours of power production. These plants could play a key role in keeping the grid reliable and resilient. But without adequate data on PSH development costs or performance, it's difficult to compare PSH to other technologies to identify which could maximize grid performance and reliability.

What Is the Pumped Storage Hydropower Cost Model Tool?

NLR's open-source, bottom-up PSH cost model tool estimates how much new PSH projects might cost based on specific site specifications like geography, terrain, construction materials, and more. The tool integrates data from users—including assumptions about PSH reservoir, dam, and conveyance characteristics—along with other design decisions, like reservoir volume and assumptions about indirect costs.

Using these data points, along with physical relationships and component cost equations, the tool builds a cost estimate for individual PSH projects.

The cost model is available as a downloadable spreadsheet with all underlying data and formulas or as an easy-to-use web application. These formats let users choose how they want to interact with the tool.

How To Use the Cost Model Tool

The PSH cost model can calculate capital costs for a closed-loop PSH system that requires two new reservoirs. Users can remove, ignore, or substitute cost categories to suit their needs, or they can use default data representing a typical PSH facility. The spreadsheet tool has separate calculations for small (25 megawatts or less) and large PSH systems. The web application defaults to a large system and is fully integrated with the NRL PSH life cycle impacts assessment tool, enabling cost, impact, or combined analysis.

The cost model calculates the following:

- Performance specifications for PSH components, such as hydraulic head, power output, and discharge flow rates

- Component-level unit costs, total component costs, and total plant costs

- Estimated total direct and indirect construction costs for a PSH system.

The cost model includes key specifications for a wide range of PSH infrastructure and provides definitions for all input specifications, assumptions, and PSH site components.

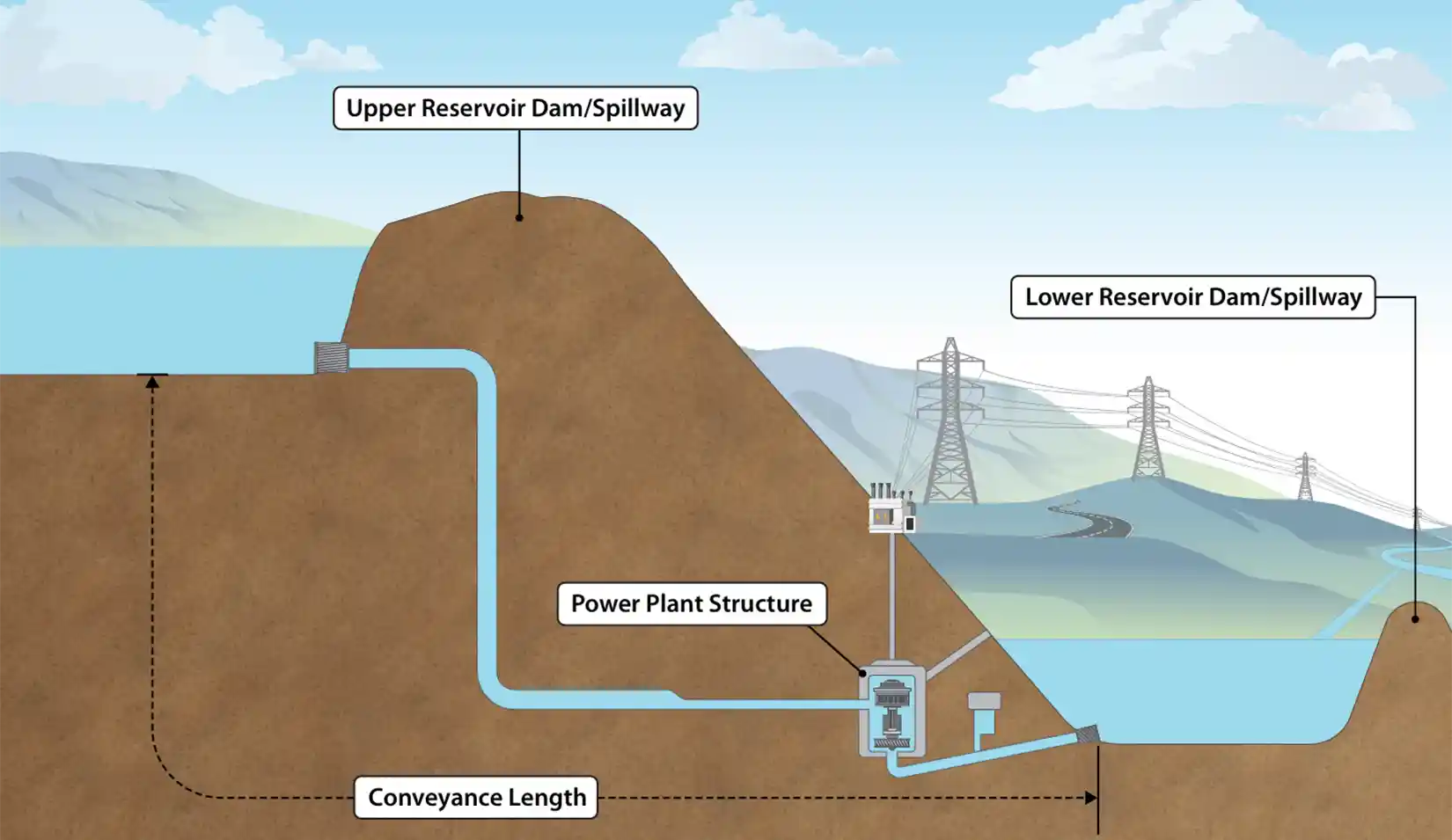

A simplified PSH system schematic shows key components included in NLR's PSH cost model, such as the dam/spillways, power plant structure, and water conveyance. Graphic by Besiki Kazaishvili, National Laboratory of the Rockies

The cost model calculates plant performance specifications using physical and empirical relationships along with representative PSH system assumptions. When users enter reservoir, dam, and conveyance characteristics, the tool then calculates dam material volume, reservoir volume, and tunnel characteristics.

The tool estimates head, discharge, and power output at minimum, mean, and maximum power output conditions while incorporating empirical head loss from pipe friction as well as component efficiencies. The resulting quantities define the PSH facility's power production and energy storage potential. The user's assumed storage duration governs the relationship between power production and storage.

After the tool determines key PSH plant specifications, the model:

- Calculates direct component costs as a unit cost* (e.g., cost per foot or per kilowatt)

- Multiplies the unit cost by the estimated unit quantity (e.g., number of feet or kilowatts) and any applicable cost adjustment factors like inflation, locational differences, and non-inflation market rates.

After calculating direct costs, the model determines the indirect costs using markup rates for each indirect cost component (e.g., tax, contingency). The total plant cost is then the sum of direct and indirect costs.

* Unit costs are calculated using data provided by industry consultants or parametric relationships adapted from the Electric Power Research Institute's "Pumped-Storage Planning and Evaluation Guide." NLR researchers digitized the report's data and methods by extracting points from report figures and fitting them with regression models.

To validate the cost model, NLR researchers consulted with hydropower industry representatives and compared the tool's cost estimates to publicly available costs associated with several proposed projects, including the Eagle Mountain Project (California), Goldendale (Washington), Gordon Butte (Montana), Seminoe (Wyoming), Swan Lake (Oregon), White Pine (Nevada), and Lewis Ridge (Kentucky).

Although component costs vary depending on cost categorization, design details, and indirect cost assumptions, modeled total cost projections are well within the expected uncertainty range of the cost modeling tool (−30% to +50% or greater). The NLR team will continue to validate and adjust default assumptions in the model based on data collected from real projects that are currently in development and continued consultation from industry professionals.

Given the uncertainty in cost estimates, the model is set up to allow rapid sensitivity analysis to explore alternative input assumptions and their impact on costs. In addition to simple manual updates to individual inputs, the spreadsheet tool includes a macro-enabled parametric simulation feature that enables users to quickly explore several key input assumptions at a time.

The current PSH cost model has several limitations (some of which could be addressed in future versions):

- The model is useful for screening and for determining study feasibility, which implies an accuracy no better than −30% to +50% at both the component and total cost level (this is due to the inherent uncertainty in PSH design and construction).

- The model may be highly sensitive to atypical PSH project specifications that fall outside the bounds of the cost model equations.

- The model does not yet include additional component disaggregation, such as within the power station, which could improve cost estimates.

- Market adjustments are used in the model to create cost relationships, which could have limited accuracy (particularly those from the 1990 Electric Power Research Institute report), and users might choose alternative adjustment factors based on their

market knowledge.

- The model makes no estimation about how costs might change in the future based on technological improvements or other factors.

- The model exclusively estimates capital costs and does not include fixed or variable operations and maintenance costs.

- The model does not include any policy or financial considerations. These must be incorporated by the user as adjustments on the cost model result.

The first-generation cost model uses methods described in a 2023 NLR technical report.

The second-generation cost model released in December 2025 includes several enhancements and additions. Alternative dam materials like rockfill and roller-compacted concrete are now available using methods described in a 2025 NLR technical report. An option to select variable-speed pumps is now available that increases pump-turbine costs by 20% and powerhouse costs by 5% based on industry consultation. A liner cost component has been added, with the liner area calculated as the minimum required area if both the reservoir surface and the dam form isosceles triangles. Unit costs for geomembrane liners are derived from Oak Ridge National Laboratory's geomembrane cost model for a moderate-cost configuration (single-liner) and a high-cost configuration (double-liner with leak detection), and other liner materials use a conservative cost estimate based on available industry data. The material/equipment cost percentage is now used only for sales tax calculations and updated indirect cost definitions are more descriptive. Lastly, the market adjustment factors now use a combination of industry-supplied factors that adjust costs through 2022 and data from U.S. Bureau of Reclamation Construction Cost Trends to adjust to subsequent years. This approach allows market adjustment factors to be updated annually as U.S. Bureau of Reclamation Construction Cost Trends data are published.

References

A Component-Level Bottom-Up Cost Model for Pumped Storage Hydropower, NLR Technical Report (2023)

Methods for Assessing Ring-Dam Pumped Storage Hydropower Opportunities, NLR Technical Report (2025)

NLR’s Pumped Storage Hydropower Cost Model Spreadsheet Tool, YouTube

Learn more about PSH and other hydropower and marine energy technologies at NLR's REDi Island, and watch a YouTube video about PSH operation.

View all NLR publications about PSH and hydropower.

Partnerships

The NLR PSH cost model was developed in consultation with HDR Inc. and Small Hydro Consulting LLC, which provided data, validation, advice, and review of the tool. These two industry partners provided perspectives across a range of potential PSH project sizes, which enables unique cost model characteristics for larger versus smaller PSH systems.

Contact

Share

Last Updated Dec. 24, 2025