Battery Microstructures Library

Use this library of three-dimensional lithium-ion (Li-ion) battery electrode microstructures for microstructure characterization and microstructure modeling.

The library features a variety of Li-ion cathode (nickel manganese cobalt [NMC]) and anode (graphite) electrode data samples, calendered and uncalendered with different loadings.

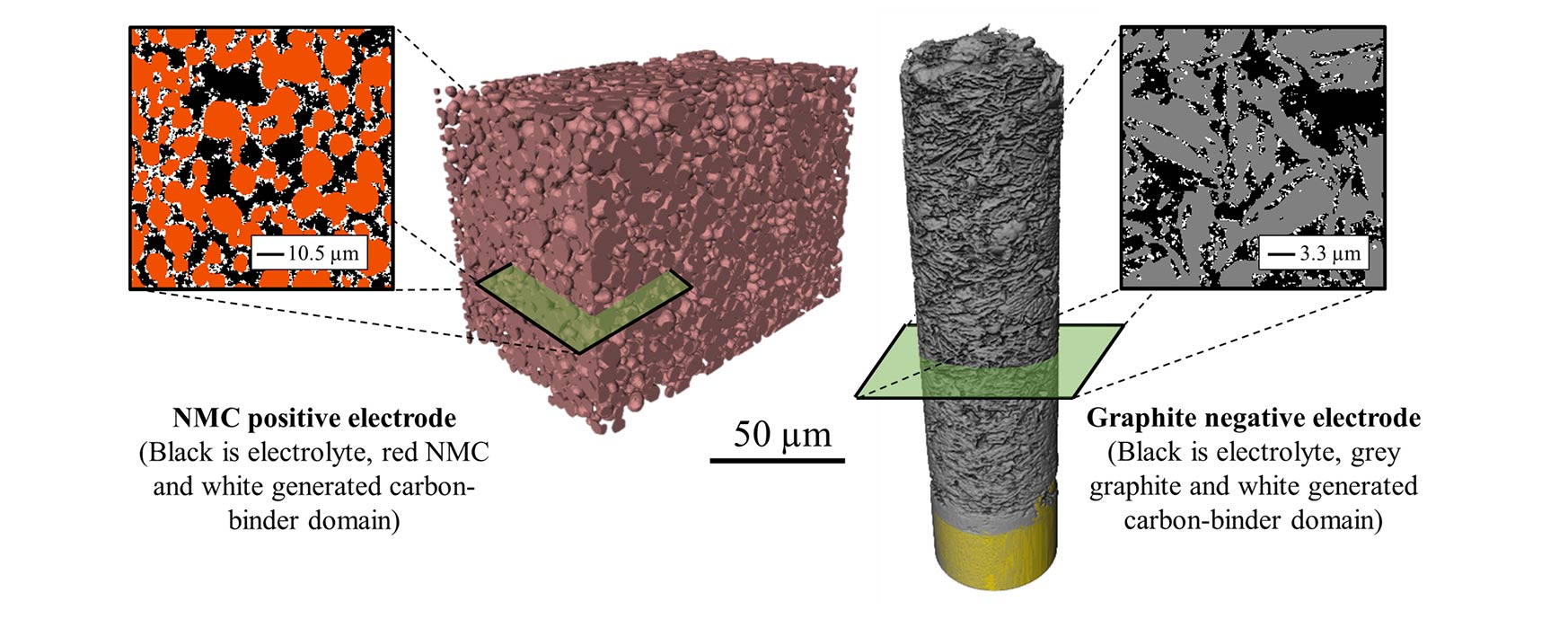

Example segmented volumes of three-dimensional electrodes.

Nickel Manganese Cobalt and

Graphite Data Samples

Samples available in the library for download include both grey-level and segmented, three-dimensional volumes.

A variety of Li-ion cathode (NMC) and anode (graphite) electrode samples, calendered and uncalendered with different loadings were fabricated by the Cell Analysis, Modeling and Prototyping facility at Argonne National Laboratory. University College London then imaged the electrodes with X-ray tomography. Since X-ray tomography is unable to distinguish the carbon-binder inert phases from the pore, a physics-based approach developed by Purdue University has been used to numerically generate the carbon-binder domain. For more information about how the data was collected, segmented and analyzed, see Resolving the Discrepancy in Tortuosity Factor Estimation for Li-ion Battery Electrodes through Micro-Macro Modeling and Experiment.

Li-ion battery performance is strongly correlated with microstructure morphology. Physics-based battery models most often use porous electrode theory and macro-homogeneous assumptions to predict electrochemical response. In these models, microstructural heterogeneity of battery composite electrodes is abstracted in terms of effective (or macroscopic) properties, such as particle diameter, porosity, specific surface area, and tortuosity. Fine determination of these parameters is essential to accurately predict electrode performance and degradation.

Publications

Resolving the Discrepancy in Tortuosity Factor Estimation for Li-ion Battery Electrodes Through Micro-Macro Modeling and Experiment, Journal of The Electrochemical Society (2018)

Quantitative Microstructure Characterization of an NMC Electrode, ECS Transactions (2017)

Share

Last Updated Nov. 17, 2025