Battery Failure Databank

The Battery Failure Databank features data collected from hundreds of abuse tests conducted on commercial lithium-ion batteries. Methods of abuse include nail penetration, thermal abuse, and internal short-circuiting.

This databank provides the heat output from cells undergoing thermal runaway, the breakdown of heat from the cell casing and its ejected contents, as well as the mass of the cells before and after thermal runaway and the quantity of mass ejected from the cell. The databank also organizes the stored data for understanding test-to-test variability for each cell type and trigger mechanism combination.

Additionally, most tests feature associated high-speed X-ray radiography videos for review alongside the data.

Databank Contents

In the databank spreadsheet, each test is allocated a test identifier that includes:

- Synchrotron at which the test was conducted (ESRF for The European Synchrotron or DLS for Diamond Light Source Synchrotron)

- Month and year (Oct 18, Feb 19, etc.)

- Test number for that experimental session (Run001, etc.).

Note: Some experiments in the databank were not associated with a synchrotron experiment. Those tests were conducted at the Johnson Space Center and have a different test identifier.

Most synchrotron test IDs are hyperlinked to a corresponding X-ray video on YouTube. Imaging and test information (e.g., frame rates, type of cell, abuse method) are provided in the YouTube descriptions. Note: Tests that were conducted outside the synchrotron facilities do not have an associated X-ray video.

Also, the databank spreadsheet provides:

- Cell models and geometries in the Cell Description and Cell Format columns

- The type of abuse test (thermal, nail, or internal short-circuiting)

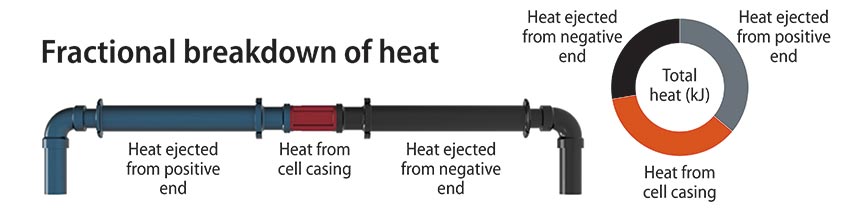

- The total heat output as the Corrected Total Energy Yield, followed by the fractions of this heat from the cell body, positive end, and negative end of the cells

- The average heating power applied to the calorimeter and length of time to trigger thermal runaway

- The post-test cell mass and the mass ejected from the positive and negative ends.

The databank spreadsheet has a "readme" tab that describes the contents of the columns in more detail.

Abuse Tests

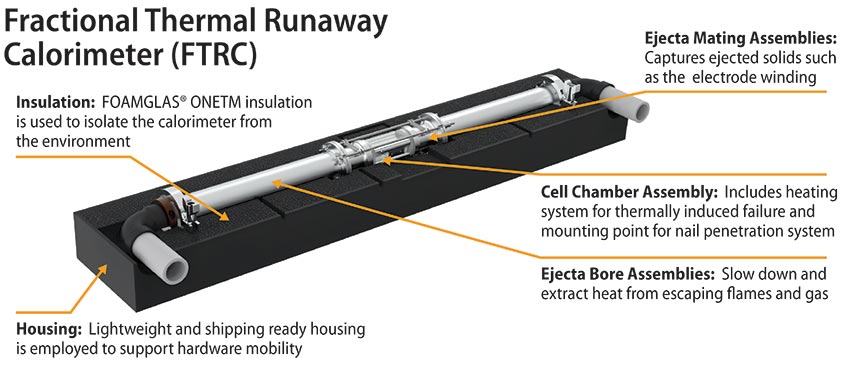

Abuse tests were conducted on several battery cell formats (18650, 21700, and D-cell) and for different models from various original equipment manufacturers. A fractional thermal runaway calorimeter (FTRC) was used for each test, which decouples the heat output from ejected materials (solid, liquid, and gas) and from that which is conducted through the casing of the cell itself. The FTRC data gives insight into the total heat generated and how much heat is ejected from each cell type for each abuse method.

The figure below shows a breakdown of tests in the Battery Failure Databank, where filenames correspond to the experimental time and location on the left of the figure.

Test Data from the Battery Failure Databank

Illustration showing the breakdown of experiments with test-location (left), cell model (middle), and trigger mechanism (right). View test data from the Battery Failure Databank.

Calorimetry and Mass Data

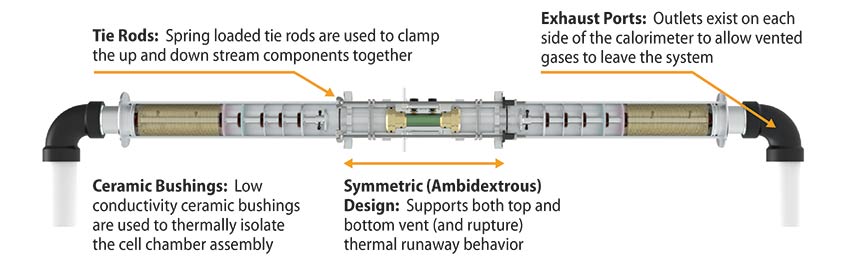

An FTRC was designed for quantifying the total heat output from cylindrical cells undergoing thermal runaway as well as distinctly quantifying the fraction of heat that was conducted through the casing of cells and from material ejected from the positive or negative ends of the cells. The mass of cells before thermal runaway, as well as mass of cells after thermal runaway, were recorded to facilitate the quantification of relationships between ejected mass and fractional heat output. An illustration of the FTRC is below. For more detailed information about the FTRC, read the Journal of Power Sources article. Also see the NASA presentation Enhancing Battery Safety with Fractional Thermal Runaway Calorimetry.

Illustration showing the components of the FTRC (top) as well as a color-coded image of the fractions of heat measured from the cell casing and its ejected contents (bottom).

Radiography Videos

For many of the tests, high-speed X-ray radiography of the thermal runaway was simultaneously recorded at a synchrotron facility. These videos are hyperlinked into the Battery Failure Databank spreadsheet, and details about the imaging conditions are provided in the descriptions of the individual videos on YouTube. The X-ray radiography videos provide insight into the rapid structural dynamics that occur within the cell during thermal runaway, facilitating linking internal events to the thermal response of cells.

Watch this video of time-stamped radiographs from a video showing the propagation of thermal runaway inside an 18650 cell. Here you can see the inside of the cell reacting to thermal triggers. Note: This video has no audio.

Publications

The Battery Failure Databank: Insights from an Open-Access Database of Thermal Runaway Behaviors of Li-Ion Cells and a Resource for Benchmarking Risks, Journal of Power Sources (2024)

Decoupling of Heat Generated from Ejected and Non-Ejected Contents of 18650-Format Lithium-Ion Cells Using Statistical Methods, Journal of Power Sources (2019)

Modelling and Experiments To Identify High-Risk Failure Scenarios for Testing the Safety of Lithium-Ion Cells, Journal of Power Sources (2019)

Characterising Thermal Runaway within Lithium-Ion Cells by Inducing and Monitoring Internal Short Circuits, Energy & Environmental Science (2017)

Identifying the Cause of Rupture of Li‐Ion Batteries during Thermal Runaway, Advanced Science (2017)

Tracking Internal Temperature and Structural Dynamics during Nail Penetration of Lithium-Ion Cells, Journal of the Electrochemical Society (2017)

Acknowledgments

This work was supported by NASA Johnson Space Center, University College London, and Oxford University. The radiography videos were acquired at beamline ID19 at ESRF – The European Synchrotron and beamline I12 at the Diamond Light Source Synchrotron.

Contact

Share

Last Updated Jan. 2, 2026