Solar Manufacturing Cost Analysis

NLR analyzes manufacturing costs associated with photovoltaic (PV) cell and module technologies and solar-coupled energy storage technologies.

These manufacturing cost analyses focus on specific PV and energy storage technologies—including crystalline silicon, cadmium telluride, copper indium gallium diselenide, perovskite, and III-V solar cells—and energy storage components, including inverters and batteries.

These analyses are often based on bottom-up cost models for multiple components along the supply chain, offering a detailed look at cost drivers. The key outputs of these analyses are:

- Minimum sustainable prices

- Step-by-step and total manufacturing costs for a given process, to identify cost drivers

- Roadmaps identifying potential pathways for cost reduction.

Minimum Sustainable Price

Many NLR manufacturing cost analyses use a bottom-up modeling approach. The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled. Input data for this analysis method are collected through primary interviews with PV manufacturers and material and equipment suppliers.

This approach enables NLR to estimate step-by-step costs and identify cost drivers for a given material and production process.

Bottom-Up Manufacturing Cost Modeling

Many NLR manufacturing cost analyses use a bottom-up modeling approach. The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled. Input data for this analysis method are collected through primary interviews with PV manufacturers and material and equipment suppliers.

This approach enables NLR to estimate step-by-step costs and identify cost drivers for a given material and production process.

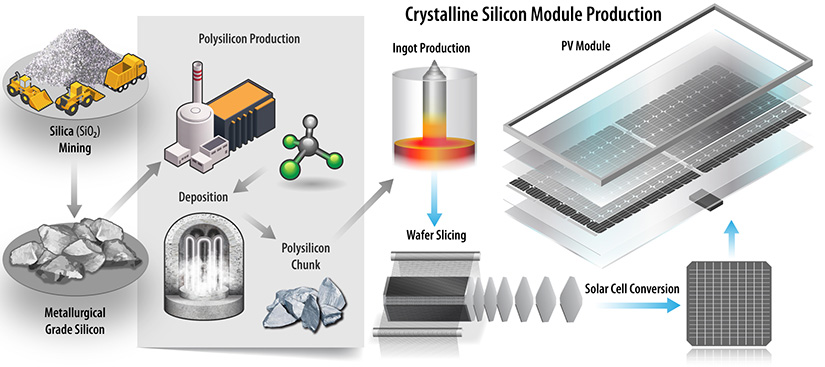

NLR researchers consider the full production processes of solar cells and modules when conducting bottom-up cost modeling.

Historical and Future Cost Modeling

Since 2010, NLR has been conducting bottom-up manufacturing cost analysis for certain technologies—with new technologies added periodically—to provide insights into the factors that drive PV cost reductions over time.

NLR also creates roadmaps that illustrate how innovations, increased production volume, and other factors could drive future cost reductions.

View the Historical Cost Model Results for Solar PV Module Manufacturing chart on Tableau.

Detailed Costs Analysis Model

The Detailed Costs Analysis Model (DCAM) on Open EI is a cloud-based tool for calculating the costs to manufacture components and install energy systems. DCAM underpins many of NLR’s solar manufacturing cost analyses.

Publications

Photovoltaic (PV) Module Technologies: 2020 Benchmark Costs and Technology Evolution Framework Results, NLR Technical Report (2021)

Research and Development Priorities to Advance Solar Photovoltaic Lifecycle Costs and Performance, NLR Technical Report (2021)

Crystalline Silicon Photovoltaic Module Manufacturing Costs and Sustainable Pricing: 1H 2018 Benchmark and Cost Reduction Road Map, NLR Technical Report (2020)

III-V-Based Optoelectronics with Low-Cost Dynamic Hydride Vapor Phase Epitaxy, Crystals (2019)

Find more solar manufacturing cost analysis publications.

Tutorials

Watch these videos to learn about NLR's techno-economic analysis (TEA) approach and cost modeling for PV technologies. They're part of NLR's Solar TEA Tutorials video series.

Approach and Methodology for Techno-Economic Analysis of PV Modules

Cost Modeling for Specific PV Technologies

Contact

Project Lead, Energy Technologies, Economics, and Policy Analysis

Share

Last Updated Jan. 28, 2026