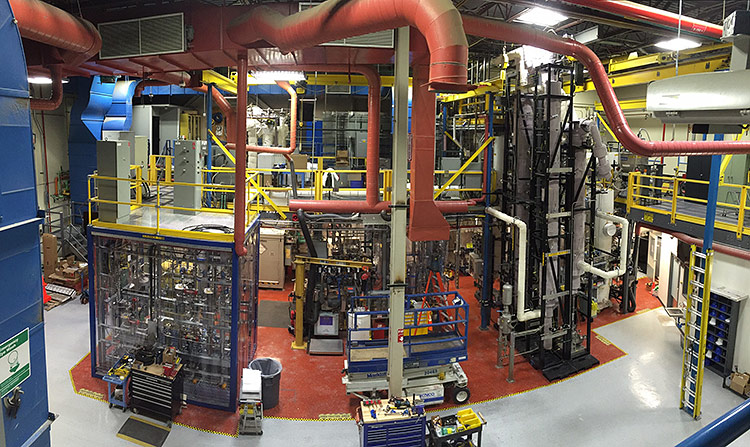

NREL’s Thermal and Catalytic Process Development Unit can process 1/2 ton per day of biomass via fast pyrolysis or steam gasification. The new catalytic riser reactor system can be used for ex situ vapor-phase upgrading or steam reforming with continuous catalyst regeneration. Get more information about NREL’s Thermochemical Processes.

Research Interests

- Integration and scale up of biomass to fuels and chemicals

Affiliated Research Programs

Areas of Expertise

-

Fabrication of pilot-scale reactors, vessels, piping, and tubing

-

Welding—metal inert gas (MIG), tungsten inert gas (TIG), and orbital

-

Electrical wiring (AC and DC)

-

Tube bending and long tubing runs

-

Pipe fitting

-

Plant operations

-

Sampling and sample handling

-

Hoisting and rigging

-

Auto CAD

-

SolidWorks

-

Microsoft Office

Education

-

B.S., Business Management, University of Colorado, 2007

-

A.A., Colorado Mountain College, 2004

Professional Experience

-

Research Technician, National Renewable Energy Laboratory, 2014–present

-

Metallurgical Technician, Hazen Research, 2013–2014

-

Lead Technician, Phillips Enterprises, LLC, 2008–2013

Share

Last Updated Nov. 17, 2023