III-V Single-Junction and Multijunction Solar Cells

We develop advanced III-V solar cell technology and share our results by publishing in high-impact journals and transferring the resulting intellectual property to industry.

We have a distinguished record of accomplishment in the field, including the invention of the original gallium indium phosphide/gallium arsenide (GaInP/GaAs) multijunction cell, its transfer to the high-efficiency cell industry, and the invention and development of inverted metamorphic multijunction (IMM) cell technology.

Our Expertise

We have expertise in:

- Developing advanced III-V solar cell architectures for terrestrial and space applications

- Epitaxial growth and processing of ultrahigh-efficiency III-V multijunction solar cells

- Metamorphic materials science and engineering

- Growth of challenging new III-V alloys

- Characterizing and analyzing multijunction photovoltaics

- Developing and applying experimentally grounded device physics models of multijunction cell performance

- Numerical modeling of cell performance, including effects of luminescent coupling, inhomogeneous illumination, cell heating, and three-dimensional flow of electrical current

- Developing III-V photovoltaics for high-temperature operation, photoelectrochemical hydrogen production, and thermophotovoltaic structures for energy storage applications.

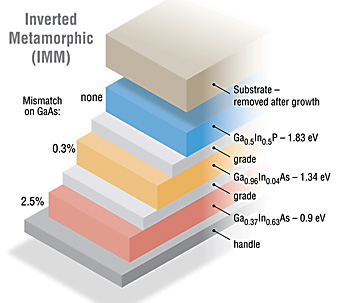

In this three-junction IMM solar cell, high-performance subcells are realized by: (1) inverting the usual growth order, growing mismatched cells last, (2) engineering a transparent buffer layer to mitigate dislocations, and (3) removing the primary substrate/attachment to the secondary "handle."

Research Areas

The efficiency and concentration of III-V multijunction solar cells can be highly leveraged to reduce the cost of high-concentration photovoltaic systems. In 2015, we demonstrated ~46% efficiency with a four-junction IMM solar cell using a compositionally graded buffer to incorporate nearly perfect single-crystal layers with different crystal lattice parameters. More recently, we extended the concept to a six-junction IMM solar cell with three lattice-matched and three mismatched subcells, demonstrating 47.1% efficiency at 143 suns. These devices contain more than 100 independent layers of varied alloy content and are arguably the most complex optoelectronic devices in the world. The research advances the scientific understanding of dislocation nucleation and glide in III-V alloys to achieve low threading-dislocation densities in ternary and quaternary junctions. We are also studying techniques to grow metastable compositions of quaternary III-V alloys and mitigate oxygen-related defects in aluminum-containing alloys. Our work improves the understanding of the physics of the complex optoelectronic multijunction solar cell devices concerning light emission, relatively high light-injection levels associated with high concentration, and small device sizes.

Standard III-V epitaxy is limited to materials with nearly the same lattice constant as the host substrate. Through early thermophotovoltaic work and more recent IMM development, NLR has become a leader in the field of metamorphic epitaxy, or the deposition of materials with lattice constants other than the host substrate. In theory, metamorphic epitaxy opens the available palette of III-V materials considerably, enabling solar cells with wide-ranging bandgaps such as those demanded by the six-junction IMM solar cell or emitters with wide-ranging emission wavelengths such as LEDs and lasers. Controlling dislocation behavior and confinement of dislocations to inactive layers within the solar cell is critical, and research involves studying dislocation nucleation and glide, interaction with material properties, and their impact on device performance.

Solar cell efficiencies can be pushed toward thermodynamic limits by reducing parasitic optical losses, extending the range of photon absorption, and minimizing nonradiative recombination. We are developing two-junction GaInP/GaAs cells with highly transparent carrier confinement layers that also include two-dimensional quantum nanostructures to extend the range of photon absorption. Three-junction GaInP/GaAs/GaInAs IMM cells will include a thin graded buffer and a ~1.0-eV third junction, with a goal of demonstrating >40% efficiency.

III-V multijunction cells can generate sufficient voltage and current to spontaneously split water, thereby producing hydrogen that can be stored. The original GaInP/GaAs photoelectrochemical cell was developed at NLR, and we have continued to improve efficiencies by using IMM and quantum well architectures. Our work is funded through the DOE HydroGEN Advanced Water Splitting Materials consortium, and we have several academic partnerships investigating methods for improving the stability, durability, and efficiency of these devices.

III-V multijunction solar cells power the majority of satellites. NLR has played a role in the development of space solar cells by transferring GaInP/GaAs multijunction technology and developing radiation-tolerant III-V solar cell components. NLR has the unique ability to create challenging III-V materials and has expertise in a suite of characterization tools for analyzing proton and electron radiation effects, such as deep-level transient spectroscopy and admittance spectroscopy.

Excess electricity can be stored in the form of very high-temperature heat and recovered by means of thermophotovoltaic cells. With external partners, we are developing GaAs, GaInAs, and tandem IMM cells for energy storage applications, funded by ARPA-E

and Shell/GCxN. In addition to high photovoltaic efficiency, the cells are designed to have very high sub-bandgap reflectance to boost the thermophotovoltaic system efficiency to >50%. We also develop cells for other thermophotovoltaic applications,

including as the heat-to-electricity converter in power generation systems and for the conversion of waste process heat to electricity.

To learn more about thermophotovoltaic cells, read The Right Resources To Develop Thermophotovoltaic Technologies.

NLR has extensive expertise and capabilities for the development, fabrication, characterization, and analysis of photovoltaic cells with optimal bandgaps for power-beaming receivers. We develop PV receiver cell architectures with extremely high performance over a range of bandgaps from 0.6–2.1 eV (wavelengths from 600 to 2000 nm) and beyond, and irradiances as high as 100 W/cm2. We also have extensive capabilities for optoelectronic characterization and analysis of these PV cells, including testing under high-irradiance illumination.

To learn more about optical power beaming, read Reliable Power for Remote Applications.

Tools and Capabilities

We use the following as we develop and transfer multijunction cell technology:

- Cluster tool, which comprises a metal-organic vapor-phase epitaxy growth system connected via load locks to a molecular-beam epitaxy growth system and an analytical chamber

- Two stand-alone metal-organic vapor-phase epitaxy growth systems

- Stand-alone molecular-beam epitaxy growth system

- Cleanroom in which epitaxial wafers can be processed into full devices

- Suite of cell testing techniques, including current-voltage and quantum efficiency testing of full multijunction cells

- Numerical modeling of cell performance issues relevant for incorporation into real-world systems, including inhomogeneous illumination, cell heating, and three-dimensional flow of electrical current.

Contact

Share

Last Updated Dec. 6, 2025