Copper Indium Gallium Diselenide Solar Cells

NLR has significant capabilities in copper indium gallium diselenide (CIGS) thin-film photovoltaic research and device development.

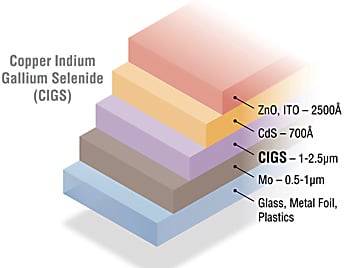

CIGS-based thin-film solar modules represent a high-efficiency alternative for large-scale, commercial solar modules. CIGS is a versatile material that can be fabricated by multiple processes and implemented in different form factors. For example, CIGS can be deposited on substrates such as glass, metal foils, and polymers. Metal foils and polymers allow for applications that require lighter-weight or flexible modules.

Over 20-plus years of research, NLR CIGS scientists developed several advances in the technology, including the "three-stage process" for fabricating the CIGS absorber layer. This process enables the formation of a CIGS thin-film layer that is of the proper composition and structure to allow the photo-generated charge carriers to exist long enough in the CIGS layer of the device so that they can be separated and collected at the front and back contacts. This separation and collection is critical for demonstrating high conversion efficiency.

Our Expertise

We have expertise in:

- Fabrication of all CIGS solar cell layers

- Co-evaporation of CIGS absorber layers

- Three-stage process

- Evaporation + selenization

- Bandgap grading

- Alkali incorporation

- Materials characterization

- Device modeling and characterization

- Cell-level reliability.

Research Areas

Our primary research areas include:

CIGS alkali treatments

Alkali post-deposition treatments have been instrumental in dramatic voltage improvements that have increased small-area CIGS device efficiencies from 20% to beyond 23%. We are using NLR’s unique capability to study CIGS surfaces without air exposure to gain a fundamental understanding of alkali treatments for high-efficiency thin-film solar cells.Cell-level reliability

Most reliability testing is done at the module level. We also use research-scale samples to document and solve issues such as reversible metastability, potential-induced degradation, and shading-induced damage.Effects of material and process choices

NLR scientists have been key in helping industry understand how cost-effective, industrially relevant process choices can impact the ultimate performance and reliability of CIGS modules.Cell reliability for advanced device designs

Although present CIGS designs can meet reliability goals for rigid modules, new CIGS products and markets (e.g., flexible products) may require a higher level of reliability. NLR is pursuing new materials for inclusion into the cell structure that will meet these requirements.

Tools and Capabilities

NLR has the ability to deposit all layers of CIGS thin-film solar cells, from 1.5-by-1.5-in. to 6-by-6in. sample sizes. We can fabricate novel materials and device structures and also perform advanced characterization and device modeling. We commonly use the following in our CIGS thin-film cell research and development:

- Sputtering systems for Mo back contacts

- Co-evaporators with electron-impact ionization spectrometer rate control for CIGS deposition

- Precursor or post-deposition treatments of NaF, KF, and other alkali-containing compounds

- Chemical bath deposition of CdS and Zn(O,S)

- Sputter systems for Zn(O,S), Cd2SnO4, Zn2SnO4, In2SnO5, and CdS deposition

- 12-by-12-in. system for ZnO and ZnO:Al deposition

- E-beam evaporation

- Suite of cell testing techniques, including current-voltage and quantum efficiency testing

- Extensive collaboration with NLR groups involved in measurements and characterization as well as materials theory to study functionality of existing materials and devices

- CIGS cluster tool, a co-evaporator tool with up to 6-by-6-in. deposition area that is integrated with sputtering and analysis capabilities to study interface formation and industrially relevant processes.

Contact

Share

Last Updated Dec. 6, 2025