Additive Manufacturing Could Turn the Tides for Marine Energy Technologies—Here Is How

Milk and cookies. Peanut butter and jelly. Macaroni and cheese. All delightfully perfect pairs. Researchers at the National Renewable Energy Laboratory (NREL) discovered another promising pair: marine energy and additive manufacturing.

Since February 2022, researchers at NREL and the Pacific Northwest National Laboratory have been exploring how additive manufacturing could complement marine energy technologies. More commonly known as 3D printing, additive manufacturing is a process that uses thin layers of material (like polymers, metals, ceramics, or others) to create a physical object from a three-dimensional model. A model is created in a digital file, which transfers to the printer.

“In the very beginning, we quickly figured out that typical plastic additive manufacturing processes wouldn’t produce strong enough components to handle ocean forces,” said Paul Murdy, a mechanical engineer at NREL and principal investigator for the marine energy additive manufacturing study. “It became apparent that it would be impossible to design this structure without using metals.”

With support from the U.S. Department of Energy’s Water Power Technologies Office to advance foundational research and development for the Powering the Blue Economy™ initiative, the NREL team has been analyzing materials and printing methods for components that make up tidal turbine blades. Through their research, experts have determined that stainless steel (a corrosion-resistant material) and laser metal deposition (an additive manufacturing method) are the most promising options for fabricating tidal turbine spars.

But what exactly is a turbine spar? A spar acts as a backbone for the turbine blade, holding the structure in place—which means that it is a critical, load-bearing component. And these components need to be extra-durable for the ocean environment.

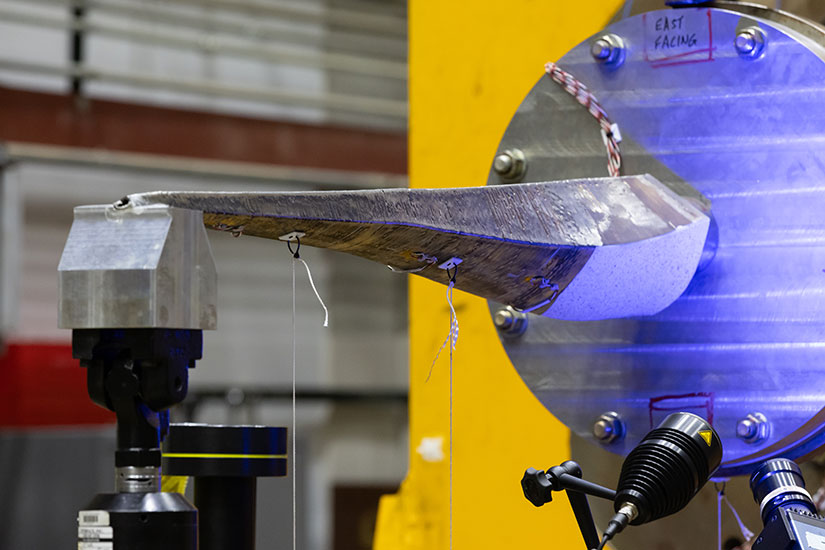

The 3D-printed stainless steel tidal turbine spar undergoes testing at NREL. Photo by Joe DelNero, NREL

“We’ve opened a really unique design space through 3D printing,” Murdy said. “This project has demonstrated that additive manufacturing has the potential to produce very strong, stiff structures that will be good for marine energy.”

Additive manufacturing could also address many of the challenges that marine energy faces, like lengthy manufacturing timelines and high costs. For example, additive manufacturing allows experts to design components with unique details—material can be added and easily taken away in different places without adding manufacturing steps or impacting timelines. Because of this, developers can test several unique designs within a much shorter time frame and with a significantly lower investment.

Miguel González-Montijo, a graduate intern at NREL who is earning a doctorate in civil engineering, designed the turbine’s spar.

“I was interested in the spar geometry and wanted to ensure that the spar’s shape, size, and geometric intricacies matched an existing marine turbine blade design,” González-Montijo said.

Miguel González-Montijo (left) and Paul Murdy (right) prepare the tidal turbine spar for lab testing. Photo by Joe DelNero, NREL

By designing a spar that can be used in existing tidal turbine technologies, the team hopes to enable rapid prototyping of marine energy devices. Having more prototypes would allow for more testing and design iterations, which would help researchers identify the most promising technologies for blue economy sectors, such as aquaculture or microgrids in coastal communities.

“For specific communities in particular places, marine energy could be a game changer,” González-Montijo said. “For example, my home, Puerto Rico, could benefit from an upgraded energy grid that incorporates renewable energy technologies like marine hydrokinetic energy. These technologies could help many small towns build energy resilience and independence while delivering locally sourced, renewable power.”

Using a combination of computer-aided design files (or CAD files) and state-of-the-art 3D-printing software, parts can be uniquely and specifically designed for different technologies and then printed to fit perfectly within the system. This technique not only allows researchers to plug and play, investigating which parts work best for certain scenarios, but it also makes marine energy much more accessible through widely used design tools (such as standard CAD software).

Say, for example, a coastal community installs a wave energy converter to help power a microgrid, but a component wears out. With access to a 3D printer, the local team maintaining the device could import a CAD file, print the part, and replace it. In other words, additive manufacturing could help build resilience and energy security in coastal regions by meeting a community’s needs quickly. Rather than depending on supply chains or driving long distances to get replacement parts, additive manufacturing could give communities much more control over their energy infrastructure.

Reaching the Testing Point

The NREL research team is now testing their 3D-printed spar to validate the design and the tools used to model and fabricate the spar.

“Structural validation is critical to ensuring that the spar will react to real-life forces in the way that our models predict,” Murdy said. “It also helps us understand how the novel additive manufacturing process differs from conventional steel manufacturing techniques and how we can account for it in future designs.”

The team plans to perform load testing by gradually increasing the amount of force and weight on the spar—maxing out at 1,900 pounds, which is 50% more than what the spar is designed to handle. Researchers will also perform fatigue testing (i.e., repeating stresses and strains) to understand how long the spar would hold up to the intensities of the ocean environment.

The team sets up the tidal turbine on a hydraulic actuator (a system that uses hydraulic power to generate linear, rotary, or oscillatory motion). Photo by Joe DelNero, NREL

“This test is the final piece for our research and will bring the project full circle,” Murdy said. “We’ve been able to take an all-encompassing approach with this project: From theoretical modeling to materialized testing, we’ve exercised all of our capabilities.”

The NREL team relied on Ai-Build to fabricate the spar itself (which took about a week to print). However, this project proved that having the capability to 3D-print these types of components would benefit the laboratory’s marine energy and water power research at large. Soon, NREL researchers will have access to a 3D printer that can fabricate similar components using metal and other innovative materials.

Once testing is complete, the NREL team will synthesize the results and continue iterating on the spar design. They will also investigate other areas where this method can further marine energy technologies.

Learn more about NREL's marine energy research. And subscribe to the NREL water power newsletter, The Current, to make sure you do not miss a water power update.

Last Updated Jan. 22, 2026