Q&A With Mou Paul: Artist Making Better Fuel Cells, Water Treatment Systems, and Cheese

Manufacturing Masterminds Series

If someone asked a 10-year-old Mou Paul what she wanted to be when she grew up, she would have said, “A great writer and a great scientist, too.” Little did she know how much more she would achieve.

Today, Paul’s impressive achievements include publishing more than 40 publications, winning several high-profile awards, and earning more than 50 patents for her scientific inventions. She also writes fictional short stories—mostly in her native tongue, Bengali—paints, draws, and sings while playing the harmonium, an instrument that looks like a piano-accordion mash-up and is common in Paul’s native country, India.

For Paul, making something—whether that is a painting or a complex molecule, like a polymer—comes with both mystery and joy. “In both painting and science, sometimes you just probe,” she said.

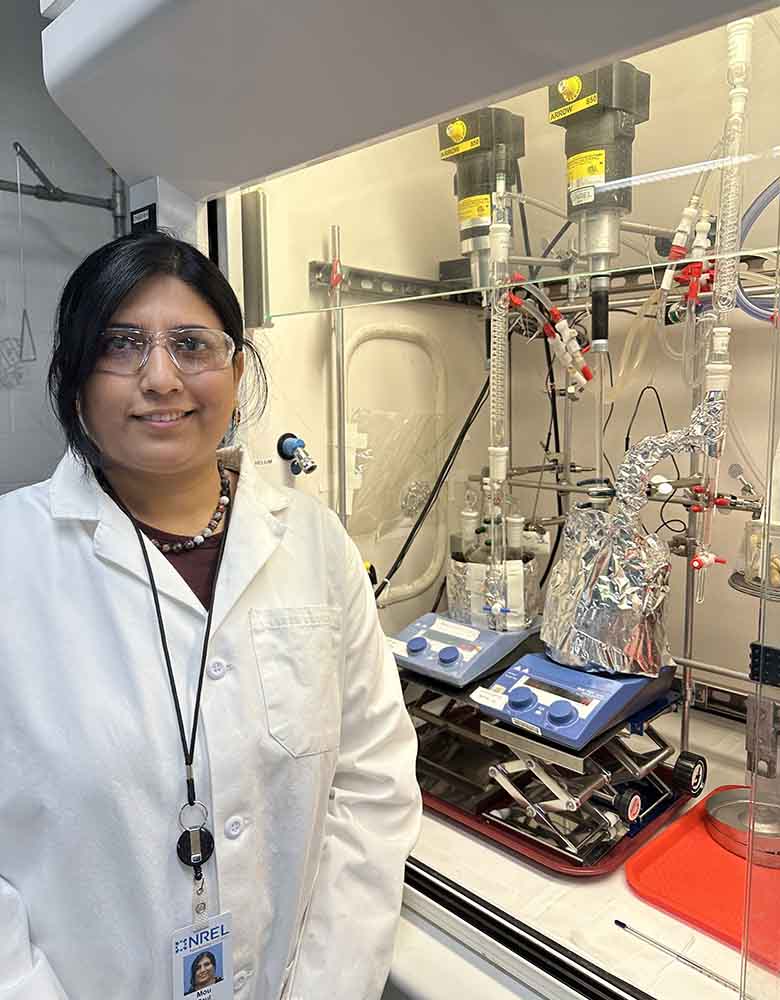

Now, as a senior staff scientist at the National Renewable Energy Laboratory (NREL), which she joined in 2021, Paul is probing polymer membranes—semipermeable barriers that block some molecules from passing while letting others slide by. These tweakable membranes are used to purify water and separate unwanted molecules to make more flavorful cheeses, for example. But they can also be used in carbon-capture technologies and fuel cells—clean alternatives to traditional automobile engines or other electricity generators.

And while cheese is great, Paul is far more passionate about designing more efficient fuel cells that even big trucks could use to drive millions of miles without emitting anything but water.

“We are still generating a lot of carbon dioxide, and global warming is increasing; the evidence of that is mounting and mounting,” Paul said. “I have seen what pollution can do.”

When she visits India in the winter, smog sits heavily above the cities, the sky perpetually shadowed by smoke. Air pollution is now considered the biggest risk factor in early death and contributes to more than 6 million premature deaths per year.

“We need to do something,” Paul said. And she is—still holding on to the mystery and joy as she probes for solutions to such a grim challenge.

In the latest Manufacturing Masterminds Q&A, Paul talks about the visual appeal of chemistry, the many ways her membranes are used, and what haunts her about the future. This interview has been edited for clarity and length.

So, you liked both math and art. How did you end up studying chemistry?

When I was in seventh grade, we experimented with phenolphthalein, which changes color to indicate if a liquid is an acid or a base. I thought that was so cool. You can see, visually, what is happening with the chemistry, water, and molecules. Math and physical science were so abstract, whereas with chemistry, you could see the effects instantly.

You went on to earn your bachelor’s degree in chemistry from the University of Calcutta in Kolkata, India. But you started to shift toward polymer science—the study of synthetic materials built from smaller parts.

Polymer science was, of course, a chemistry thing. But it involves big molecules, like the ones that build plastics. Today, polymers are omnipresent and touch every aspect of human life—clothing, medication, nutrition, transportation, communication, etc. Polymer science can help provide solutions for critical problems such as energy, water, food, and health. The field was also new and growing at that time in India. When I was growing up there, we always used newspaper for packaging; plastic bags and different forms of plastic food packaging were not yet a thing there.

Eventually, you would come full circle and study how to recycle those plastics. But first, you became enamored with fuel cells, right?

During my undergraduate studies in the early 2000s, we were told to give a seminar on any topic; I chose fuel cells. The fuel cell concept rose in popularity in the 1960s with NASA spacecraft, but it was not yet in full gear. Later, I was fortunate to join Jim McGrath and Judy Riffle’s labs at Virginia Tech where I worked on fuel cell membranes. Those membranes allow hydrogen and oxygen to interact to produce electricity—and water is their only byproduct. I was looking for an advanced technology where I could apply my fundamental skill set—polymer science—that could also solve global issues. Fuel cells ticked all the boxes.

After graduating, you spent about 13 years at Dow Chemical (or Dow, for short). What was that like?

A lot of my research was creating what the customer needed. They might say, “I need a membrane that has this much permeability or rejection.” But while you’re doing that, you might also find out what membrane structure is responsible for that property. The customer doesn't care. But that kind of discovery is why I like science. It’s like when you look at an empty canvas: You might have some colors in mind but still not know what will happen when you’re finally finished. That’s the mystery of the unknown. And then sometimes you have to do what your customer wants, which can happen in painting, too.

Why leave industry and come to a national lab like NREL?

When I was at Virginia Tech, the membranes I built could be used for fuel cells but also water desalination—removing minerals and other impurities from water. Dow had a water business at that time, so I joined them. Later, I also worked on recycling plastics at Dow.

When the NREL opportunity came up, I saw that I could work in fuel cells, water, and plastics waste through the Bio-Optimized Technologies to keep Thermoplastics out of Landfills and the Environment consortium, or BOTTLE™ for short. Everything I liked—renewables, membrane research, and plastics recycling—is at NREL. I have a lot of freedom at NREL compared to industry. I also wanted to challenge myself by broadening my experiences and progressing my career. That’s why I made the decision.

Now, at NREL, you’re working with fuel cells, water purification, sustainable packaging, waste, plastics recycling, and more. That’s a lot.

My work is at the nexus of food, energy, and water. In the energy area, that means fuel cells or electrolyzers, which are used to split water to create hydrogen for fuel cells. The same membranes can also be used for carbon capture, which could reduce carbon dioxide pollution quite a lot. It’s really difficult to directly capture carbon dioxide from the air; the technologies are still in the nascent phase. But another form, called point-source carbon capture, can be used in industrial facilities, like those that produce cement and steel, to prevent some carbon dioxide emissions.

OK. That's energy. How about water and food?

Membranes are not only used to remove salts from water. For example, in the dairy industry, we can demineralize whey to make whey powder and proteins for cheese. You can decolorize soft drinks with membranes. The pharmaceutical industry uses them to recover catalysts for making medicine. And you can separate and recycle solvents with membranes, too. At NREL, we’re using membranes to recover critical materials from wastewater and recycle minerals, waste (which can be used to create energy), and water.

There are so, so many applications! Is there a specific part of your membrane work that excites you most?

I’m a polymer chemist, so I’m interested in fine-tuning membrane chemistry so you can control which molecules can pass through.

You’re like a polymer gatekeeper.

Yes! I’m also excited about electrolysis and green hydrogen production—improving the efficiency of the water-splitting process through membrane chemistry and by developing novel polymers.

Mou Paul (left) and her husband, Abhishek Roy (right), are both senior staff research scientists at NREL, and their twin boys, Anush and Aharshi, are 9 years old. Paul is motivated to reduce pollution in our air and waterways, in part so her twin boys will inherit a cleaner Earth. Photo from Mou Paul, NREL

For folks who may be unfamiliar with green hydrogen, why is this important?

Hydrogen is a clean fuel source, but you still have to produce it without generating a big carbon footprint. That’s why producing hydrogen with electrolyzers and renewable energy is very important. We also need to rethink the whole supply chain from raw material extraction to transportation and manufacturing.

In an ideal world, what would you hope to achieve or change?

As a scientist, I think about pollution. India has some of the most polluted cities in the world, and a lot of cancers and other diseases are increasing, possibly due to pollution. As a woman, I want to see more women in Science Technology Engineering and Mathematics, or STEM. The disparity isn’t as big as it used to be, but we still don’t see a lot of women engineers or chemists.

Is that why you’re involved in mentoring both women and the younger generation?

Yes—so I feel like I can help in some way. I’m part of the National Alliance for Water Innovation’s NextGen Leadership program, which supports young professionals in the water industry.

What advice would you give to the next generation following in your footsteps?

First, I’d say renewable energy is a great research area. Come and join us! This is what the world needs.

Second, focus on your individual research but also on collaboration and team building. If you don’t network, you won’t know the many opportunities lying around. Many young professionals are unsure whether to join academia or industry. Because I’ve seen both, I would say academic labs are great for exploring fundamental research, but industry gives you a unique opportunity to see what it takes to manufacture something. It can work great on your bench top, but that doesn’t mean it will work when you are out in the world. In industry, you get to see if your invention is meaningful, sustainable, and actually works, whereas in academia, you get more flexibility and freedom for your research. Balancing both perspectives can strengthen your vision and research career.

Interested in building a clean energy future? Read other Q&As from NREL researchers in advanced manufacturing, and browse open positions to see what it is like to work at NREL.

Last Updated Jan. 22, 2026